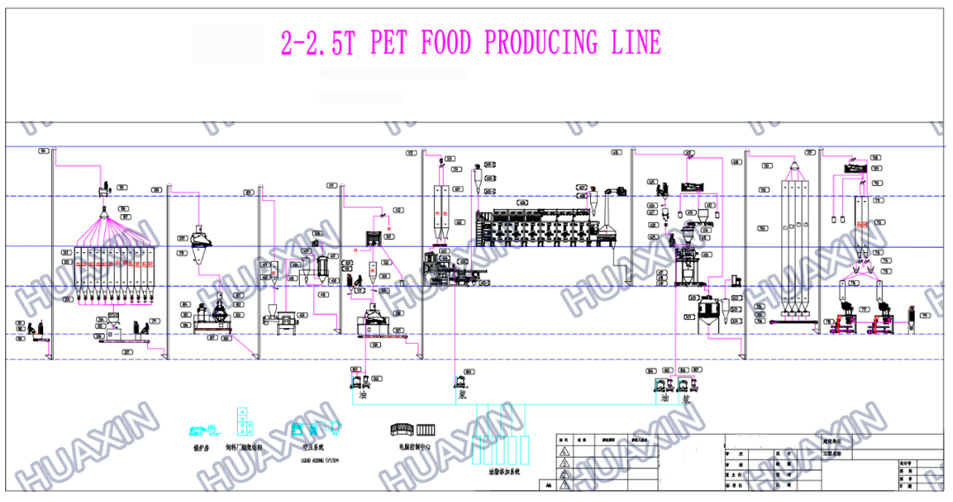

2-2.5T/h pet food production line process characteristics

The process characteristics of 2-2.5T/h pet food production line, because the customer is an open space construction, our company first considers the smooth process of the design, humanized layout in the design, adopts 4-layer steel structure design, and the workshop construction height is 19 meters.

the pet food production line process uses twice mixing, twice crushing, twin-screw extruder, vacuum spraying, countercurrent cooling, product color mixing, packaging and palletizing, etc. All automatic lines. The batching bin adopts 12 bins to meet the requirements of various formula ingredients, and the batching software adopts the Buhler system. The ingredients are stable, and a variety of formulas can be stored. The ingredient records can be kept in the file for query. The raw materials are mixed using a double-shaft paddle mixer, and the mixing uniformity is ≥98%. The twin shaft mixer has low discharge residue, which can ensure the uniformity of mixing of each batch of raw materials. The pulverizer process uses coarse powder and fine powder, and batch pulverization. Avoid the sedimentation layer caused by the sieving problem of different raw materials entering the pulverizer. For coarse crushing, a horizontal hammer mill is used, with a crushing fineness of 20 meshes and high output. The fine powder uses Ultrafine pulverizer, and the cutter head uses tungsten carbide steel, which has high hardness. The crushing fineness is 80 mesh and the sieving rate is 95%. Ensure that the molding surface of the product is smooth and free of concave and convex particles. Add trace elements and a certain proportion of oil in the secondary mixing to increase the oil content of the product. The extruder uses a twin-screw extruder, the product is stable, the drying adopts low temperature belt drying, the heat loss of trace elements is low, the spraying uses vacuum spraying, and the oil is added by 30%. The use of a counter-flow cooler with a flap has a good cooling effect. It is equipped with 4 temporary storage bins, which can store 4 different colors of products. Each bin can store products with a puffing capacity of 6 hours. Four colors can be mixed at the same time. In terms of packaging, automatic packaging scales, automatic palletizers, and belt-feeding packaging machines can be configured. The packaging specifications of 500g-25kg are all realized.