Advantages of twin screw extruder

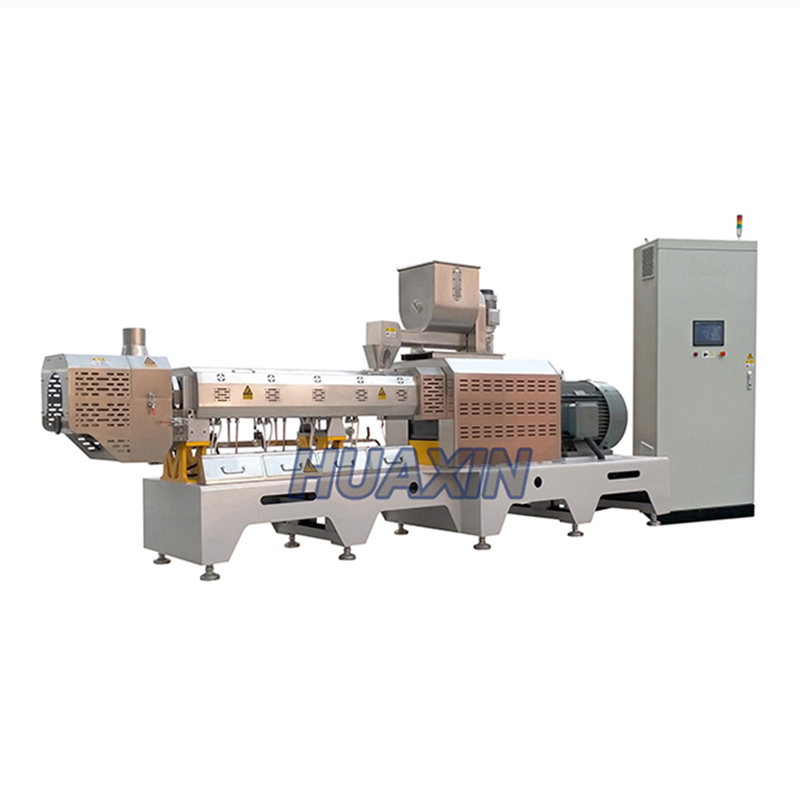

Twin screw extruder produced by our company consists of several parts, including the feeding system, extrusion system, heating system, transmission system, rotary cutting system, and control system. The material is fed into the feeding machine, and the barrel undergoes high temperature, high pressure, and high shear to expand the material to meet the required quality requirements such as organizational state.

The main features of the twin screw extruder are:

1. The feeding, rotary cutting, and main drive all adopt a frequency conversion speed control system, which has strong power, smooth operation, and saves energy.

2. The screw is made of alloy material through special processes, with a long service life; Segmented combination screw, suitable for a wide range of raw materials and a wider range of products.

3. The automatic lubrication system reduces mechanical energy consumption and extends service life.

4. The feeding system adopts double spiral forced feeding, which ensures uniform and extensive feeding.

5. Linear bearing tool adjustment system, accurate and fast tool adjustment.

6. The twin screw has self-cleaning function, making the use of equipment more reasonable and convenient.

7. Updating the technical equipment configuration of various equipment will result in a higher output of the twin screw extruder.

8. Different screws and aspect ratios can meet different production processes.

9. Visual fully automatic temperature control system to make temperature control more intuitive and parameters more accurate.

10. The overall equipment configuration is more intuitive to operate and convenient to maintain using this extruder.

The main application scope of twin screw extrusion and puffing machine:

Twin screw extruder has a wide range of adaptability to raw materials, multiple product shapes, and flexible configuration. Choosing different models and configurations can produce different products.

Currently, the main applications of twin screw extrusion and puffing machines include:

1. Produce various types of snack foods using corn and potatoes as raw materials;

2. Using flour as raw material to produce various simulated foods;

3. Using plant protein as raw material to produce tissue like protein food (commonly known as artificial meat);

4. It is made from grains, beans, or potatoes as raw materials, and is puffed into a staple food.

In addition, other products can also be produced according to different equipment combinations. For example: sandwich rice, chocolate bars, bread crumbs, nutritious rice, etc.

Expanded food is made from grains, beans, potatoes, vegetables, and other raw materials. Through the processing of expanded food machinery and equipment, a wide variety of products are produced, with exquisite appearance, rich nutrition, and crispy and fragrant taste. Moreover, the equipment for producing this puffed food has a simple structure, easy operation, low equipment investment, and fast returns.