Cereal Corn Flakes Production Line

Breakfast Cereal Corn Flake Machine Corn Flakes Production Line is a fully automatic processing line which is designed and developed from our company combining with European advanced technology.

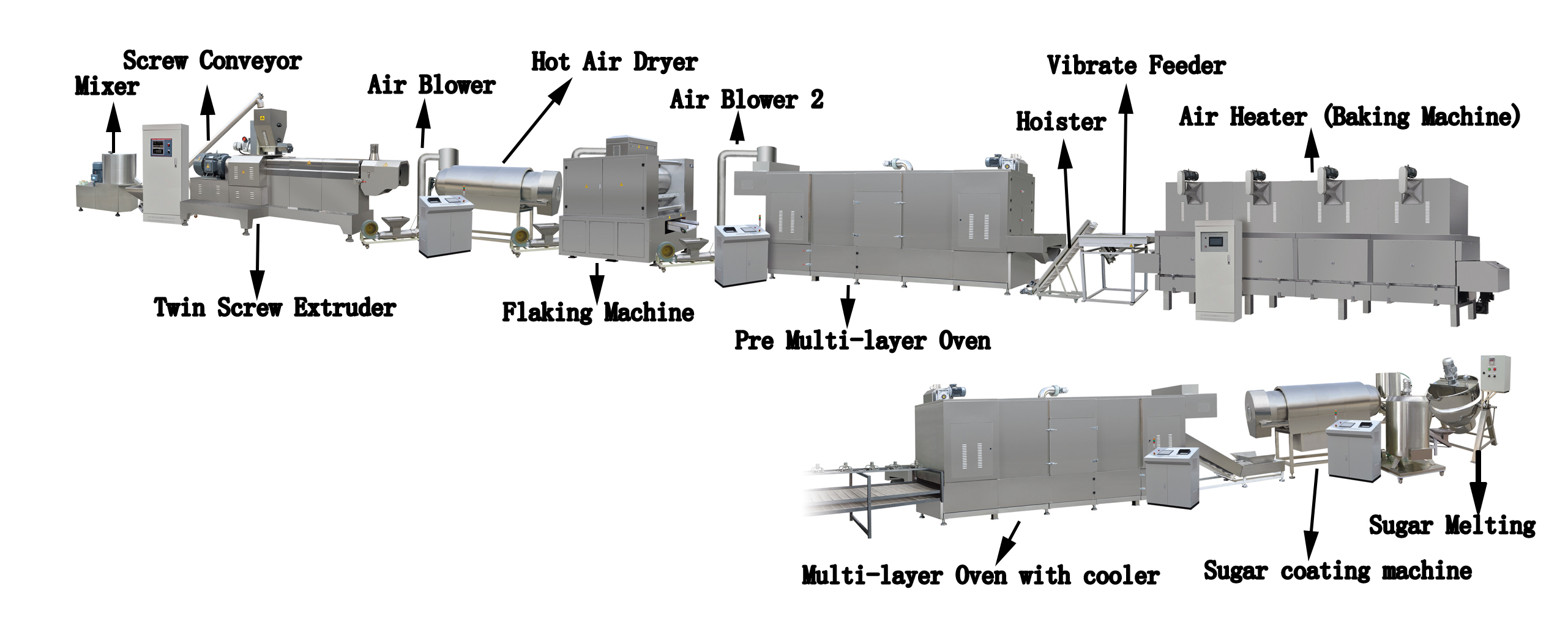

The production line uses corn flour, wheat flour, oat etc as its raw material. By twin screw extruder to accomplish cook curing, pelleting etc. Then by flakes pressing, baking, coating and other technological process to produce instant-eat crispy breakfast cereal corn flakes with regular, sweet, salty etc flavors.

Its breakthrough solves various difficult problem compared with domestic equipment, for example: pressing rollers sticking, low capacity of flakes pressing, low shaping rate, poor taste etc. Scientific processing technique can keep cereals nutritional elements.

Reasonable equipments collocation and realizable process control ensure to produce nutritional crispy breakfast cereal corn flakes with various shapes and sizes.

The processing line not only can reduce costs, but also can improves market competitiveness.

Application

Parameter

Model | Installed power | Power consumption | Output |

DS65 Corn flakes production line | 180kw | 126kw | 120-150kg/h |

DS75 Corn flakes production line | 200kw | 140kw | 200-300kg/h |

DS85 Corn flakes production line | 240kw | 168kw | 300-500kg/h |

Process: Ingredients → Mixing → Extrusion → Separation and screening → flaking → Drying → High temperature roasting → Spray seasoning (optional) → packing

Applicable materials: Rice, corn, quinoa, wheat, tartary buckwheat, oats, some legumes, etc

Material: The feeding system and surface are made of Stainless steel; The shelf and some parts are made of carbon steel; The screw and knife are made of high-strength alloy steel material

Control method: Independent electric control cabinet control; inverter control