Characteristics of the Soya Protein Processing Line

Characteristics of the Soya Protein Production Line

1. Soybean silk protein is produced using twin screw extrusion technology. This method uses a new type of twin screw extrusion food puffing machine, whose screws are designed with a combination of screws; The barrel is also a two-stage type, with each barrel individually controlled for temperature, and the barrel is equipped with a fully automatic water circulation refrigeration system that can accurately control the temperature; The computer operating system adopts a centralized intelligent monitoring system with PLC touch screen display, and various parameters during the production process can be automatically set, making it convenient, fast, and precise to control. Low temperature soybean meal, soy protein isolate, gluten powder, and other key raw materials are forcibly transported in a twin screw extruder, mixed and homogenized, crushed and pre molded, cut and melted, steamed and matured, high-temperature disinfected, and molded to produce layer by layer ductile fiber tissue, which in turn produces soybean silk protein food products with similar meat texture and taste, high toughness, and high wear resistance; According to the differences in extrusion molds and auxiliary equipment, cylinders, blocks, sheets, strips, granules, milk pudding, crumbs, and other shapes should be produced and manufactured separately; The silk drawing protein produced by this kind of twin-screw extruder has the characteristics of good moisture absorption and oil retention, good taste adaptability, and heat resistance, so it can be widely used in meat products, fast food, frozen food, stuffing, instant noodles seasoning, etc., and can also be made into dried tofu snacks and vegetarian dishes with different flavors. The silk protein production line is a complete set of fully automatic production lines, including raw material mixing, extrusion molding, drying treatment, refrigeration and other facilities, and equipped with production lines with different product yields.

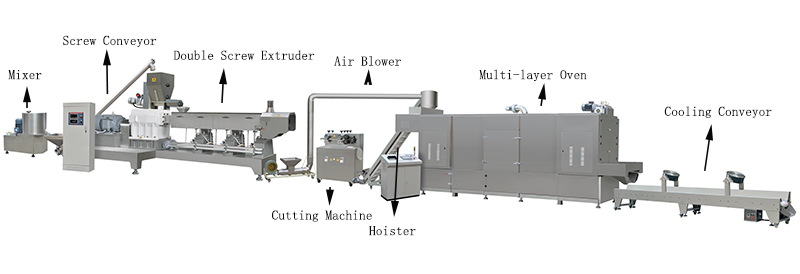

2. Production equipment configuration:

Mixer → Screw Conveyor → Double screw extruder → Cutting machine → Conveyor → Automatic multi-layer reciprocating oven → Cooling conveyor

3. Characteristics of twin screw extruder:

Touch screen control system display, precise and convenient

Direct connection transmission system between motor and gear box, with low energy loss

NSK and SKF bearings are selected with strong bearing capacity

The barrel is equipped with water injection equipment, which is more integrated into raw materials and quality standards

Screw material W6Mo5Cr4V2, strength HRC ≥ 62, sturdy and durable

Combination screw, which can be combined according to different materials and products

4. Application scope of Soya Protein:

Application in sausages and sausages: Due to its silk like properties, moisture and oil absorption, and good flexibility of its fiber tubes, soybean silk protein is used in meat products to reduce water loss and fat leakage during the production process. The product is refreshing and not greasy, which enhances the willfulness and richness of the product, enhances the protein content of the new product, and improves its quality. Application in quick-frozen Rice-meat dumplings: soybean brushed protein can enhance the toughness and taste of meatballs, and it can reduce the amount of meat used in meatballs. Other auxiliary materials of the glacier can be made into a kind of food with high protein, low calorie and low cholesterol, which can protect the higher requirements of modern people for health and reduce the loss of products in the production process.