How to make Corn flakes production line

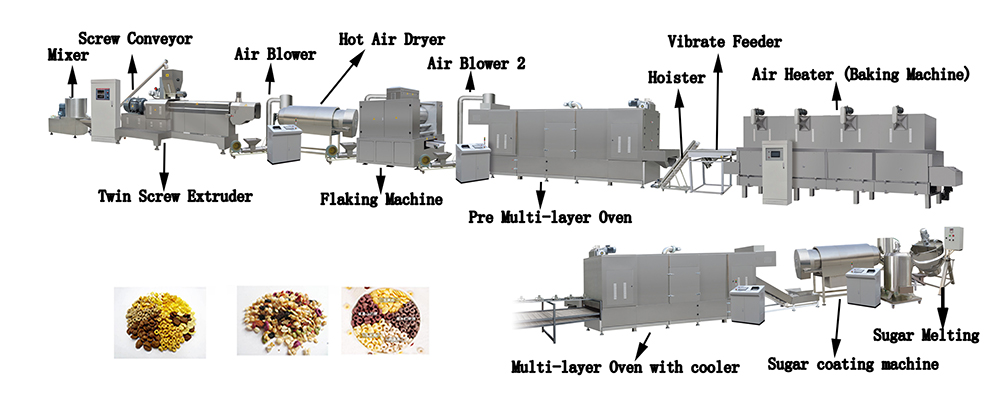

Corn flakes production line is also called breakfast cereal corn flakes production line, corn flake /breakfast cereal is one kind of crispy food, with the advantages of hard to be steeped broken and strong grain taste. It is a crispy flake that is made from cornmeal and other grains powder. The production line includes mixing, extruding, flaking, drying, high-temperature baking, flavoring, and cooling. It can be eaten like a snack, and be eaten with milk or coffee as well. By changing molds and the production process, this production line can make different shapes of puffed food. Such as ring, ball, flake, star, letter, etc.

parameter

Model | Installed power | Power consumption | Output | Cover an area | Water consumption | operator |

DS65 Corn flakes production line | 180kw | 126kw | 120-150kg/h | 200m² | ≤50kg/h | 3-4persons |

DS75 Corn flakes production line | 200kw | 140kw | 200-300kg/h | 260m² | ≤100kg/h | 3-4persons |

DS85 Corn flakes production line | 240kw | 168kw | 300-500kg/h | 300m² | ≤125kg/h | 3-4persons |

Process: Ingredients → Mixing → Extrusion → Separation and screening → flaking → Drying → High temperature roasting → Spray seasoning (optional) → packing

Applicable materials: Rice, corn, quinoa, wheat, tartary buckwheat, oats, some legumes, etc

Material: The feeding system and surface are made of Stainless steel; The shelf and some parts are made of carbon steel; The screw and knife are made of high-strength alloy steel material

Control method: Independent electric control cabinet control; inverter control