Pellet snack production line order from Indonesia client

A few days ago, we received the order from a Indonesia client for pellet extruder, with a capacity of 240-260 kg per hour.

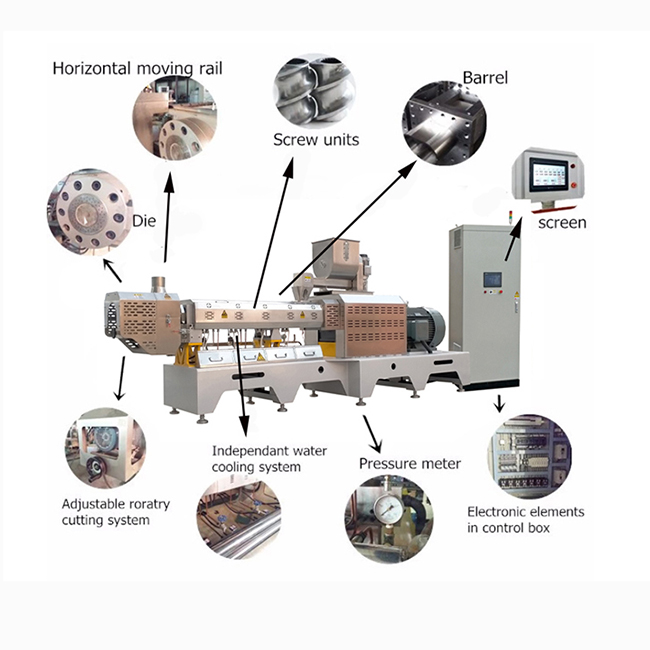

The whole production line includes mixer, twin screw extruder, shaper, cutter.

Moreover, if the client has the needs, we can also provide the automatic raw material batching weighing system and packing machine, to provide clients with a one-stop service.

Currently, the production is completed, so we do an inspection running of the production line before delivery, to ensure the production line provided to the client is without problems.

After the inspection running, the production line is running well and with good performance. All the machines meet the delivery standard.

parameter

Model parameter | DS65 pellet processing line | DS75 pellet processing line | DS85 pellet processing line |

Installed power | 120kw | 150kg | 170kw |

Power consumption | 84kw | 105kw | 125kw |

Output | 100-200kg/h | 200-400kg/h | 300-500kg/h |

Water consumption | 80m² | 120m² | 150m² |

operator | ≤30kg/h | ≤60kg/h | ≤100kg/h |

operator | 2-3persons | 2-3persons | 2-3persons |

生产流程 Process | 配料 → 混合 → 挤压膨化 → 压花 → 整形 → 输送 → 筛选 → 烘干 → 油炸 → 调味 Ingredients → Mixing → Extrusion → shaping → Drying → frying → Spray seasoning (optional) → packing | ||

适用原料 Applicable materials | Potato starch, potato flour, Corn starch, cassava starch, rice flour , flour, etc | ||

主要材质Material | 喂料系统及外壳采用304不锈钢材质;机架及部分零配件采用碳钢材质;螺杆及刀具采用高强度合金钢材质 The feeding system and surface are made of SS304; The shelf and some parts are made of carbon steel; The screw and knife are made of high-strength alloy steel material | ||

温控方式 Temperature control method | 电加热/蒸汽加热;水冷却(选配) Electric heating/steam heating; Water cooling (optional) | ||

控制方式 Control method | 独立电控柜操控;变频调速 Independent electric control cabinet control; inverter control | ||