Process of nutrient rice production line

The nutritional rice production line uses grains such as rice, corn, and beans as raw materials, which are crushed, mixed, extruded, dried, and produced into various types of nutritional rice, such as nutritional rice, functional rice, and fortified rice. The production process is automatically completed from the start of feeding, with simple operation, no dust leakage, and is hygienic and energy-saving. It can be conveniently paired with various raw materials and nutrients. Its advantage is that all kinds of nutrients necessary for human body are added to the extruded regenerated rice to adjust the balanced nutrition of human body. The product is convenient to eat, with comprehensive nutrients, good taste and convenient storage, and is welcomed by consumers and production enterprises.

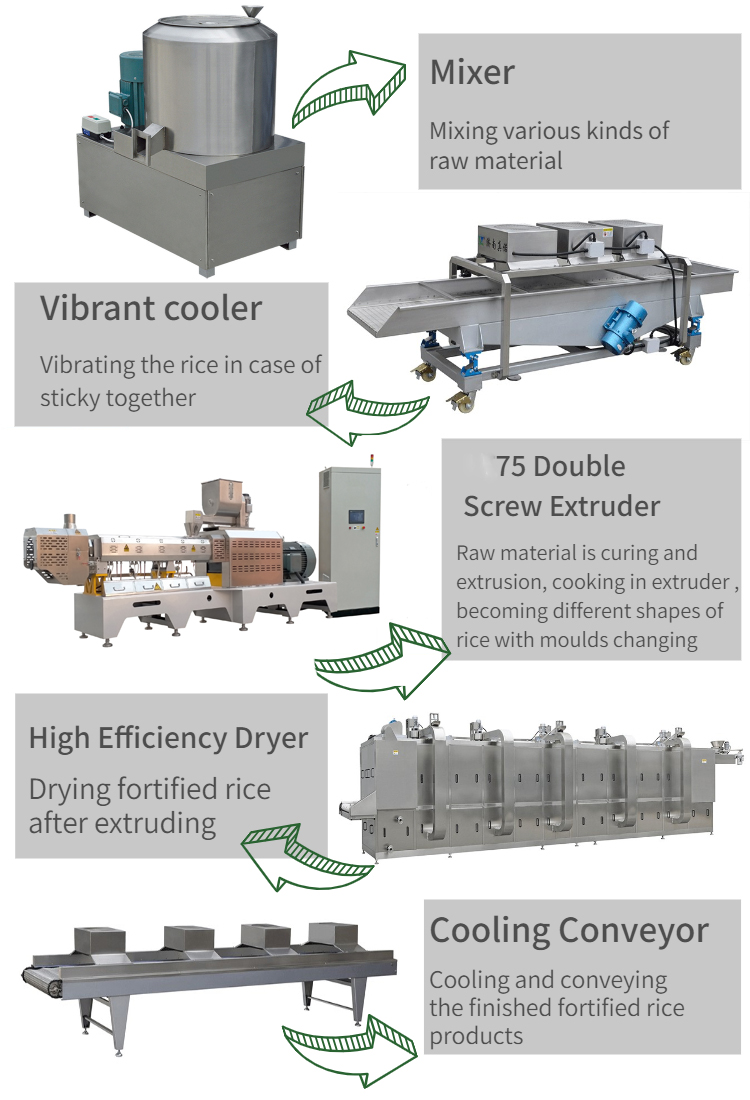

Composition of Nutritional Rice Production Line Process:

1. Powder Mixer: Rice flour is mixed with some additives alone or partially, and a certain amount of water is added to fully mix evenly.

2. Screw Conveyor: Using a motor as the power for spiral conveying, the mixed raw materials are transported to the feeding hopper of the extruder, ensuring convenient and fast feeding.

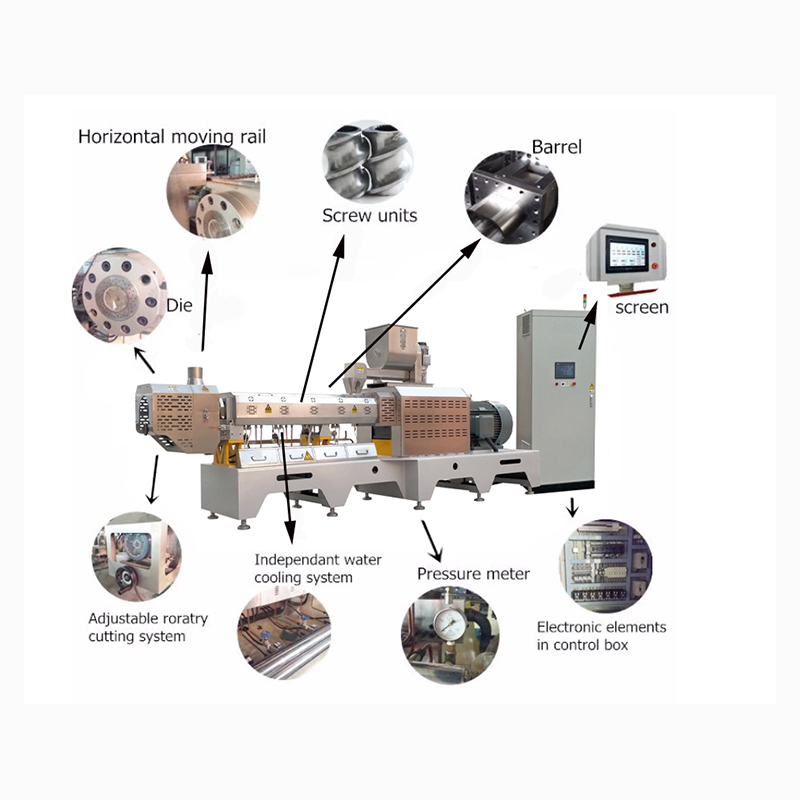

3. Extruder: There is a specialized control cabinet that can extrude rice particles in a high-pressure environment. By adjusting the process and changing the mold, different shapes of rice particles can be produced.

4. Shaker screen: The extruded particles contain a little temperature and viscosity, and are spread out through the shaker screen to avoid sticking together.

5. Air blower: Transport the product to the oven, and the height of the elevator is determined based on the oven.

6. Multi layer oven: Most ovens are electric ovens, with temperatures adjustable between 0-200 degrees Celsius through a control cabinet. The interior is made of stainless steel double layer mesh bags, and the baking time can be adjusted according to the speed, reducing particle moisture and increasing shelf life;

7. Cooling conveyor: The dried particles contain a certain temperature and are cooled to room temperature to ensure packaging quality.

This process equipment can repair and reduce the broken rice (broken rice, as well as the detached rice germ) during rice milling or process it into rice particles that are almost identical to ordinary whole rice, or according to the requirements of scientific diet, some natural nutrients such as various miscellaneous grains are mixed together in a certain proportion to make high nutritional rice and instant small food with the same cooking performance and cooking method (with flavor) as ordinary rice.