corn flakes production line, corn snack machine, pet food processing line, modified startch product

corn flakes production line, popcorn machine, snack machine, fish food processing line, modified starch production line, pet food machine, extruder

-

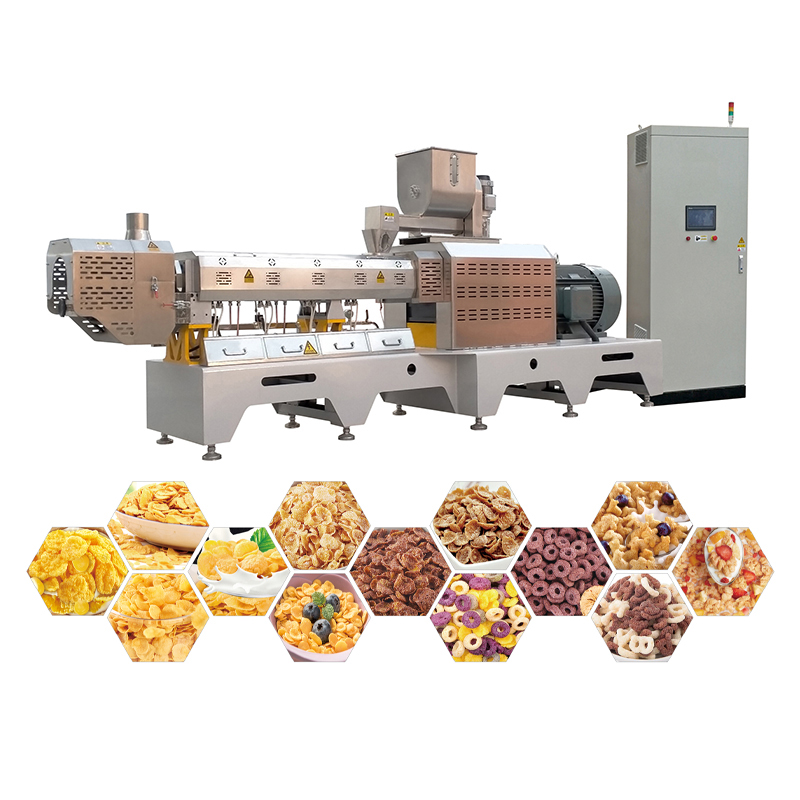

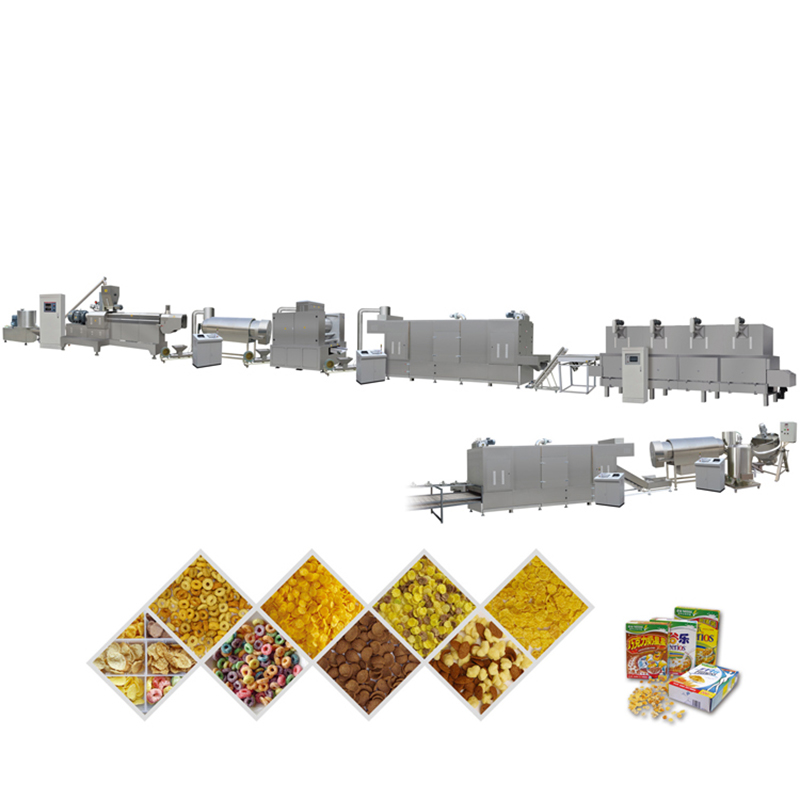

Corn Flakes Breakfast Cereal Making Machine Line

Corn flakes machine and breakfast cereals making machine use corn and other cereals as main material, through mixing,extruding or boiling, planishing, drying, baking, coating and cooling, to get crispy flakes.

-

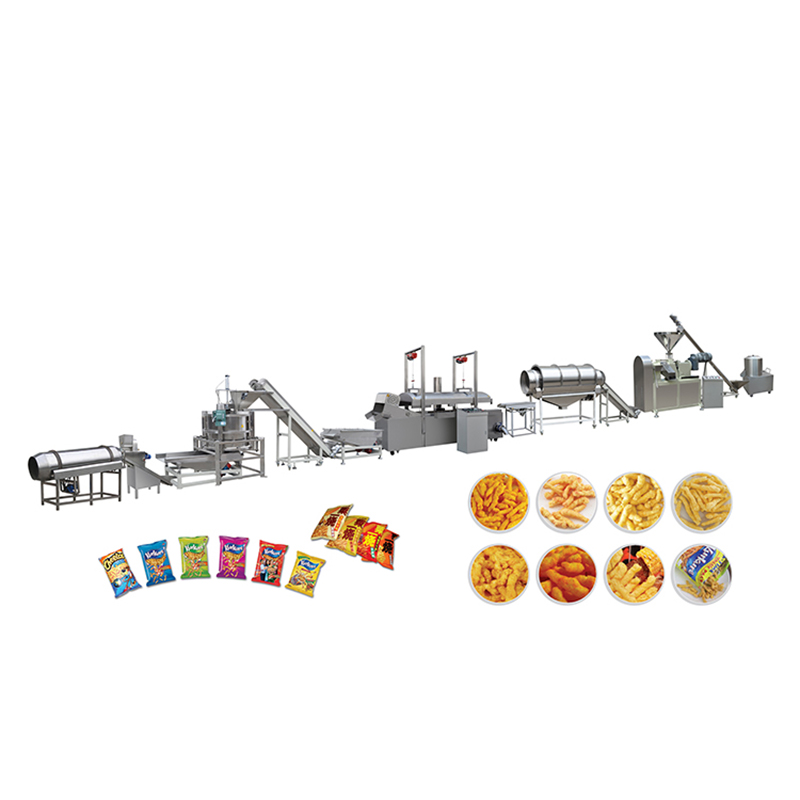

Snack Food Processing Machine

Puffed snack production line uses various natural grains, such as corn, rice, oats and wheat, as the main raw materials, and uses twin-screw extrusion technology to produce various granular, flake or profiled cereal puffed foods, such as cereal,snack, Breakfast cereal, etc; This type of product can be used as both snacks.

-

Fish Feed Processing Machine

The production line of fish grain and aquatic feed can produce various specifications of fish feed products with protein content. It can produce floating fish feed, and sink fish feed.

-

Modified Starch Pregelatinized Starch Processing Machine

Modified starch (pre gelatinized starch) production line selects Corn starch, cassava starch, Potato starch, etc. as the main raw materials according to different product needs

-

Textured Fiber Soya Protein Food Production Line

Adopt low-temperature soybean meal as main material to produce new food which looks like muscle and has the sense of mastication. This kind of food has high nutrition and can be widely applied in many industries: ham, cam, fast-food, instant-cool food etc.

-

Food Extruder Feed Extruder

The twin screw extruder is mainly composed of six parts: extrusion system, electric control system, temperature control system, transmission system, feeding system, and shaping system;

-

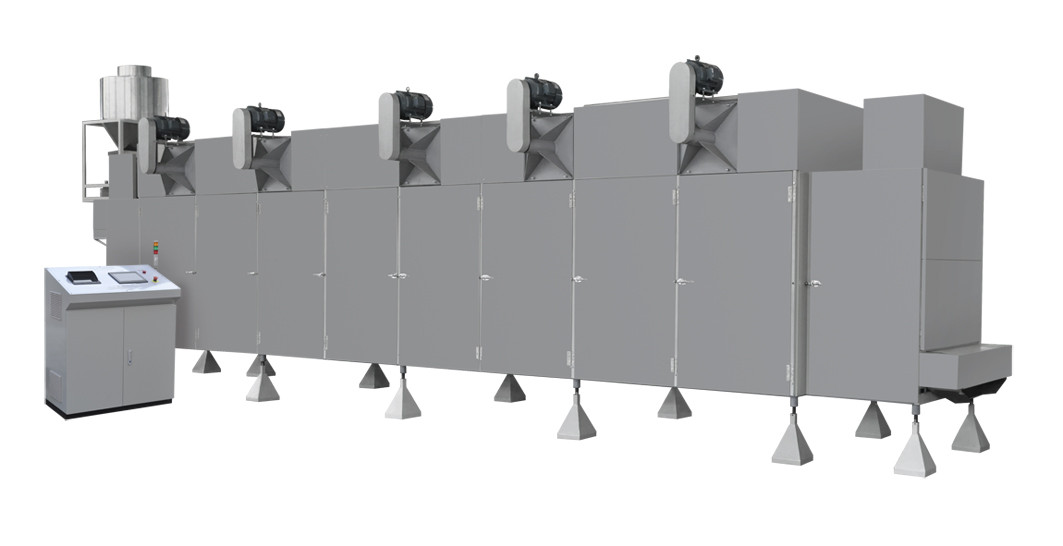

Industrial Baking Machine

The multi-layer baking machine is a commonly used baking machine in the food industry. Its core function is to dry the product's moisture, making it have a better taste and longer expire. Suitable for various types of puffed snacks, nutritional powders, breadcrumbs, pet foods, soy protein, etc.

-

Food Packaging Machine

Suitable to package fragile materials demanding high accuracy, such as puffed food, corn flakes, pet food, baby food, crispy rice, jelly, candy, pistachio, apple slices, dumpling, chocolate, small hardware’s, medicine, etc.

-

Shandong XINHUA Machinery Co., Ltd. has been committed to the research and development of corn flakes breakfast cereal making machine, and always pays attention to the dynamics of the corn flakes market. With the continuous efforts of our company, we found MAHMOOD C.W. MAHMOOD C.W. and us signed a long-term cooperative agency agreement.

Details -

Our company and technicians went to INDURMEX (located in middle American) to install and train snack processing line.

Details -

Saudi Arabia customer purchased a large frying production line

Details

Corn Flakes Breakfast Cereal Making Machine Line

Snack Food Processing Machine

Corn-filling Snacks Food Production Line

2D Twice Extrusion Snacks Production Line

3D Twice Extrusion Snacks Production Line

Fish Feed Processing Machine

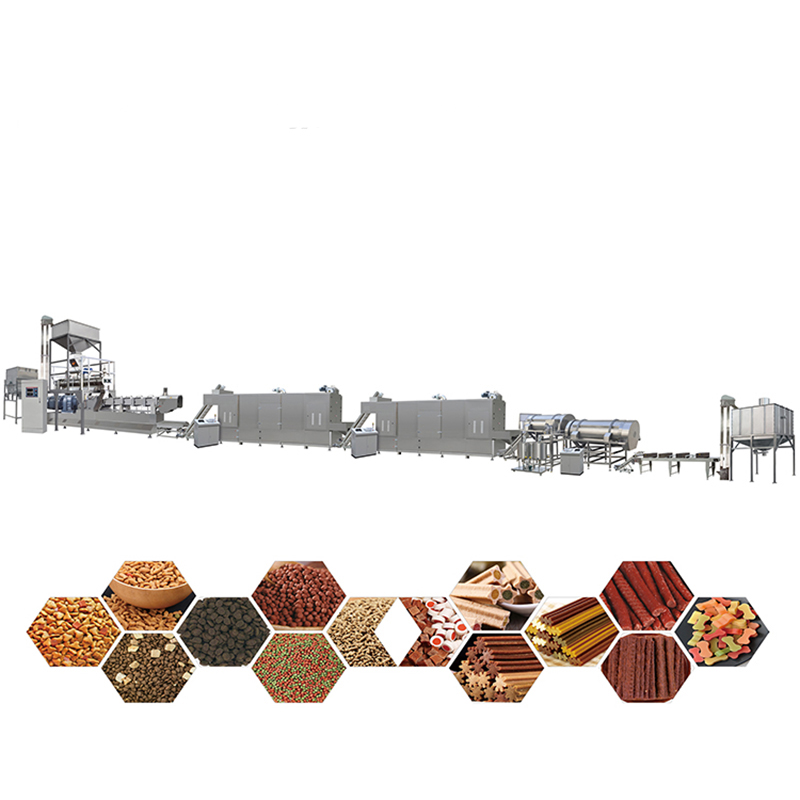

Pet Food Processing Machine

Cheetos Snacks Production Line

Popcorn Processing Machine

Nutritional Powder Production machine

Nutritional Rice Production Line

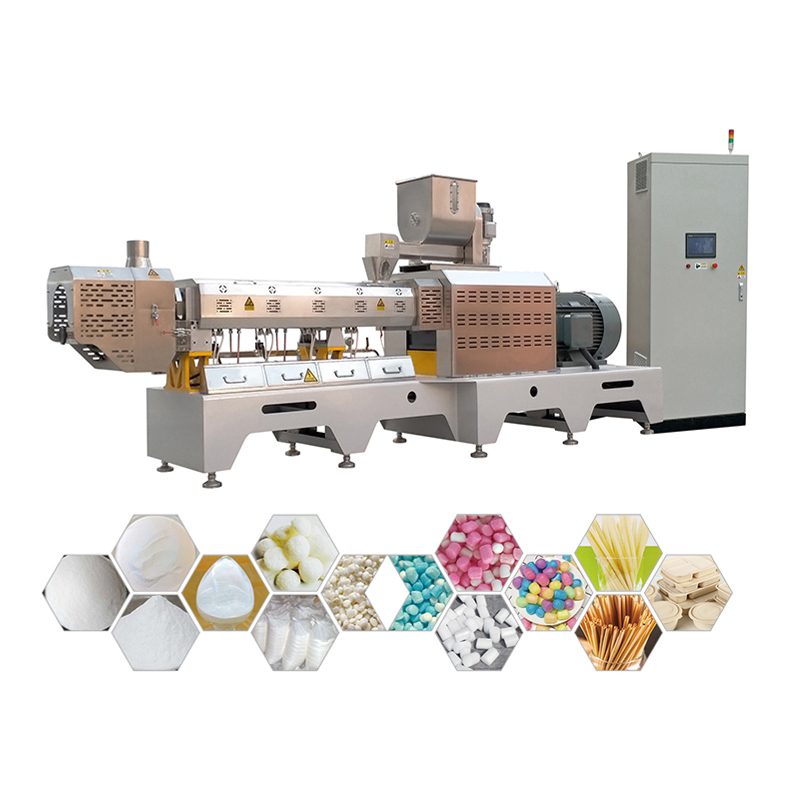

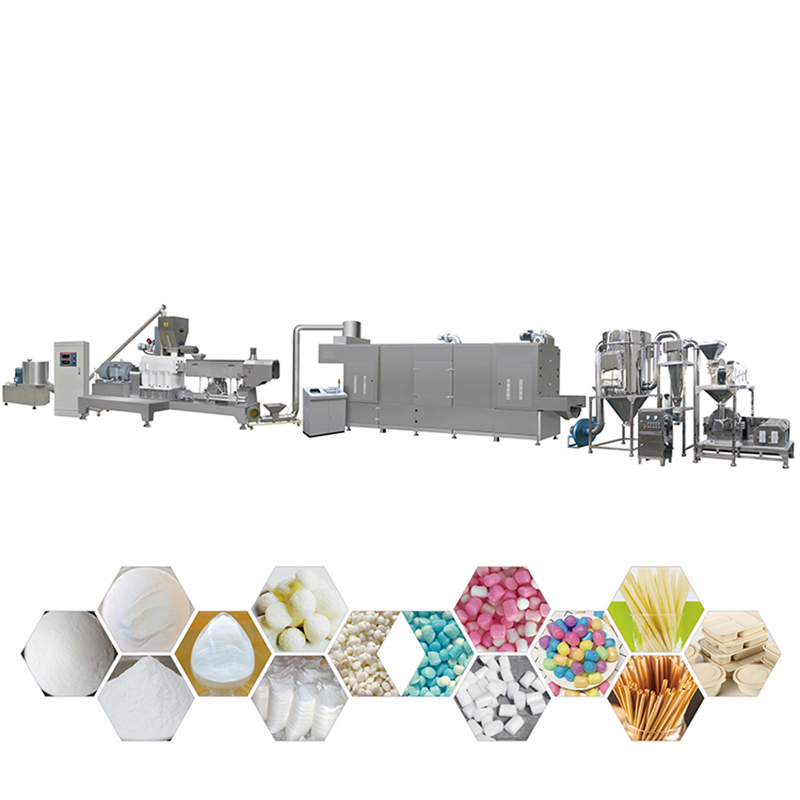

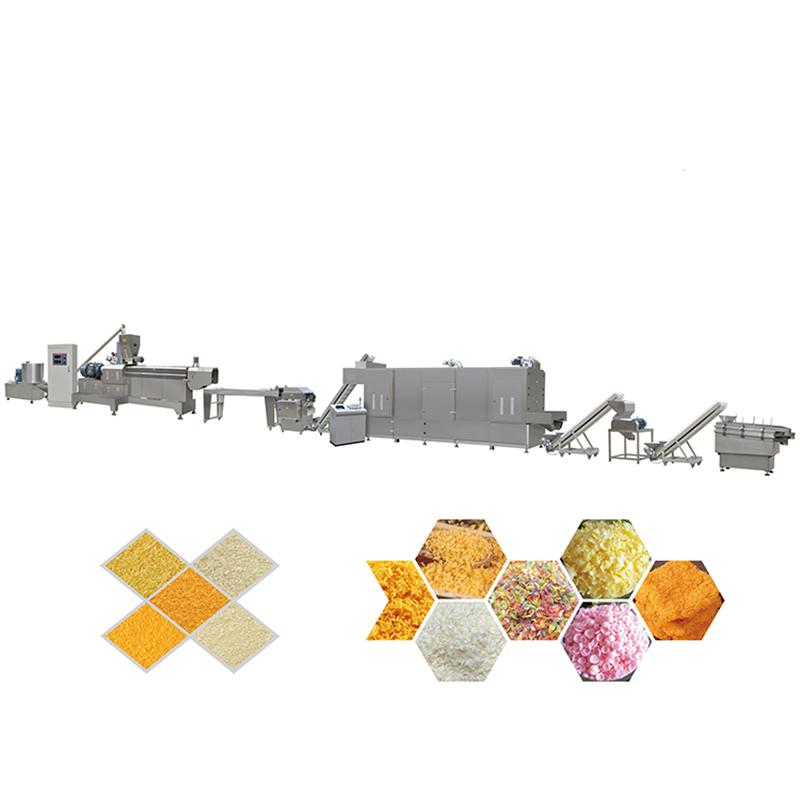

Modified Starch Pregelatinized Starch Processing Machine

Bread Crumb Production Machine

Textured Fiber Soya Protein Food Production Line

Environmental Degradable Damping Packaging Materials Production Line

Pasta Macaroni Extruder Machine

Food Extruder Feed Extruder

Industrial Baking Machine

Frying Equipment

Instant Noodles Processing Making Machine

Food Packaging Machine

Food Production Accessory Equipment

Industrial Microwave Machine

-

Pet food machine is used for processing like dogs and cats (pet food), birds, and piglets, frogs, sinking and floating aquatic feeds for fish. Which is high and new technical program as to catch the developing pet food market. Pet food line mainly use maize, fish meal, meat meal and some food additives as main raw material, through mixing, extruding, roasting, flavoring to get the final puffed pet food.

2104-2025 -

The whole production line includes convey, de-oiled machine, and controller. De-oiled machine is Centrifugal rotationing. Two drums rotate alternately, and controled by controller auto. Currently, the production is completed, so we do an inspection running of the production line before delivery, to ensure the production line provided to the client is without problems. After the inspection running, the production line is running well and with good performance. All the machines meet the delivery standard.

1404-2025 -

The brief description of Baby Cereals Food Nutrition Powder Flour Equipment Machine expertise in baby food, nutrition powder, instant drink mixes, instant fruit dessert. Ability to handle a wide range of raw materials by simply varying the temperature, moisture and drying parameters.The raw materials can be a wide range of flours and starches, pure or blended, such as rice, soy, corn, oat, millet, wheat, sorghum, banana, cassava and potato.Various recipes are supplied, which can add vitamin, mineral and other nutritional substances to meet different nutritional requirements.

0704-2025

Breakfast Cereals Making Machine Line

Floating Fish Feed Making Plant

Nutritional Rice Procressing Machine

Pregelatinized Starch Machinery

Nutritional Powder Production Line

Tvp Soya Protein Machine

Core Filled Snack Processing Machine

Feed Extruder

Gas Oven

Modified Starch Production Line

Cereal Corn Flakes Extruder

Sticky Puzzle Toys Machine

Puff Snacks Line

Dog Cat Food Making Machine

3d Pellet Extruded Snack Food Machine

Kurkure Chips Making Machine

Bread Crumbs Production Line

Puff Corn Snack Making Machine

Snack Extruder

Pregelatinized Starch Production Line