Co extruded snacks

our expertise in co-extrusion processing and creativity in die design yields distinct advantages in the development and production of co-extruded products :

- Production-proven processing techniques and scale-up expertise

- Expertly crafted co-extrusion dies with superior flow design

- Pre-engineered dies for many shapes such as bars, pillows, nuts, balls, long and short ovals and specialty profiles

- Ingredient flexibility to process a variety of cereal grains and granulations.

- Processing ability to manage a variety of filling recipes like cheese

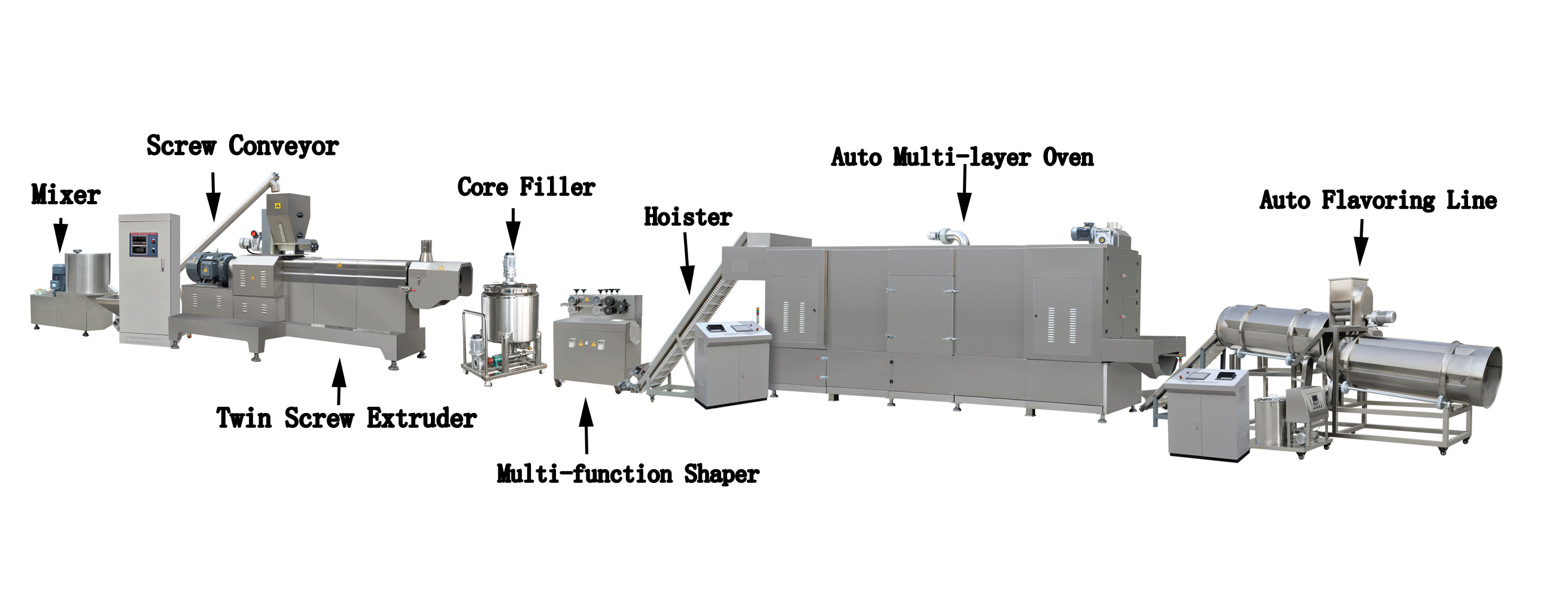

A typical co-extruded snacks processing line includes mixing and feeding vessels for both cereal shell and soft filling, twin screw extruder and forming equipment. Belt dryers and coating drums are offered for specific applications.

Model | Installed power | Power consumption | Output | Cover an area | Water consumption | Operator |

DS65 Puffed snack production line | 80kw | 60kw | 120-150kg/h | 80m² | ≤30kg/h | 2-3 persons |

DS75 Puffed snack production line | 105kw | 85kw | 200-300kg/h | 120m² | ≤60kg/h | 2-3 persons |

DS85 Puffed snack production line | 125kw | 105kw | 300-500kg/h | 150m² | ≤100kg/h | 2-3 persons |