Direct expanded snacks

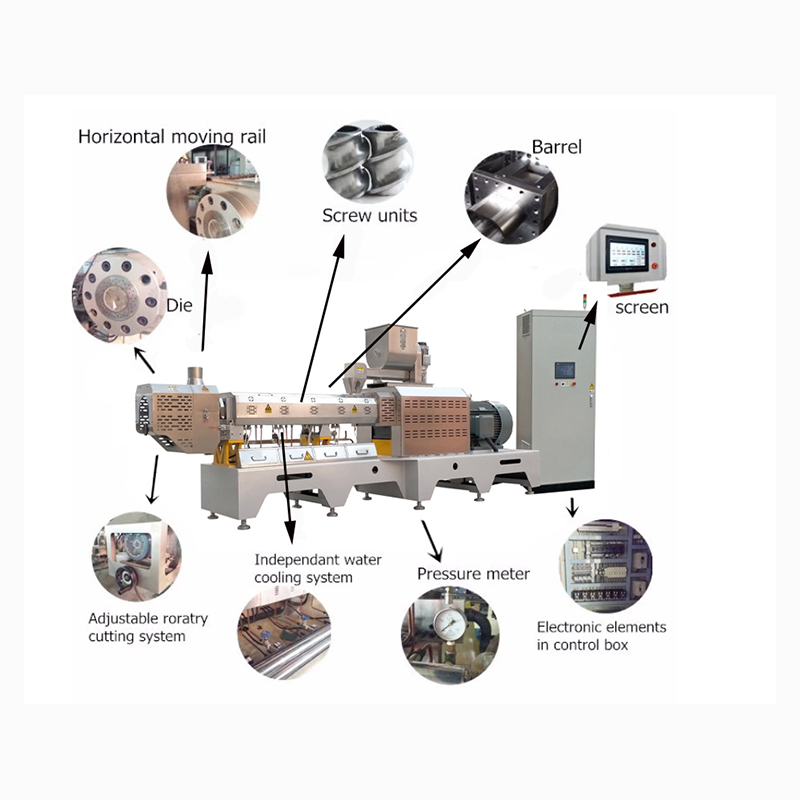

Direct expanded snacks are processed in the twin-screw extrusion lines from ours.

Innovative shapes, tempting textures, trendsetting color combinations... expanded snacks offer unlimited variety.

Our twin-screw snack extrusion lines offer unique advantages for snack processors, including:

- Simple operation with repeatable results

- Infinitely variable production parameters to achieve specific texture, density and mouthfeel requirements

- Advanced technology to process bi-colour and bi-texture snacks

- Ingredient flexibility to process virtually any cereal grain and granulation

- True process flexibility with modular, segmented barrel design plus quick change die and cutter designs to

quickly adapt to product trends

- High quality, low maintenance design and construction.

A typical snack processing line includes bulk ingredient storage and feeder, twin screw extruder, dryer and coating drum.

Parameter

Model | Screw diameter | Main motor power | Output | Dimension | Weight |

DS65 Extruder | 65mm | 22kw | 150kg/h | 2.7*0.9*1.9m | 1500kg |

DS70 Extruder | 70mm | 30kw,37kw,45kw | 250kg/h | 3.6*0.9*1.9m | 1600kg |

DS75 Extruder | 75mm | 55kw,75kw | 250 -350kg/h | 4.9*1*1.9m | 2800kg |

DS80 Extruder | 80mm | 75kw | 300-500kg/h | 4.9*1*1.9m | 3000kg |

DS85 Extruder

| 85mm | 55kw,75kw | 300-500kg/h | 5.8*1.2*2.5m | 3000kg |