Pet feed production line

Pet feed production line can adjust process parameters such as raw materials, temperature, and moisture to make the product have novel shape, rich taste and nutrition, and delicate texture, suitable for different pet flavors. This production line is suitable for the production of dog, cat, fish, shrimp, and various pet feed, and is an ideal choice for different manufacturers. With the continuous increase of the types of pets, all kinds of pets are different from adult and puppies, and the requirements for Pet food are also increasing. According to this market demand, our company has developed and cooked multiple models of Pet food production lines, which also have various configurations according to different output.

Process flow Pet food production line:

Raw material preparation →mixing → conveying → extrusion →conveying → drying → oil spraying → seasoning → cooling → screening → packaging

Equipment configuration of full-automatic Pet food production line:

Mixer → feeding machine → extruding machine → conveyor → multi-layer oven → seasoning line → cooling conveyor → vibrating screen → packaging machine

1. Mixer: Different models of mixers (vertical mixer and horizontal mixer) are configured according to different yields, including vertical (25-50kg/h) and horizontal (200-1500kg/h)

2. Feeding machine: Use spiral conveyor to transport to a certain height, and the feeding speed is fixed.

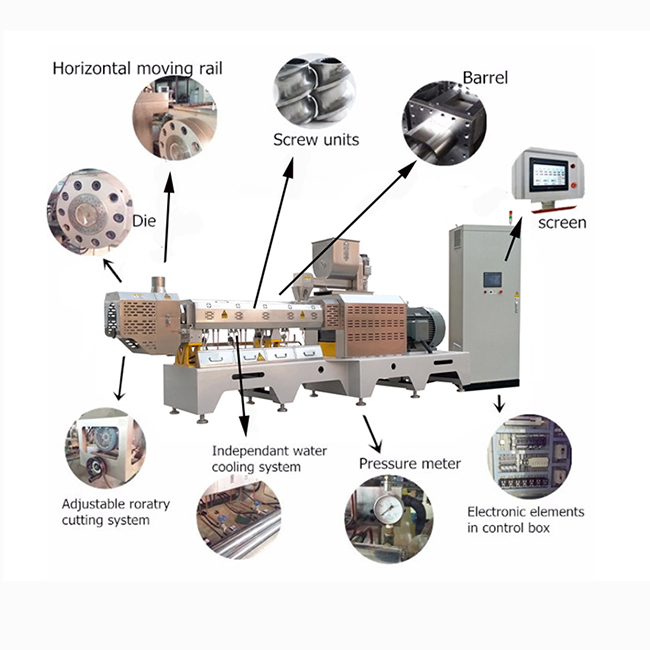

3. Expander: different models of extruder are configured according to the different output of the production line. The output varies from 100kg/h to 3500kg/h. Corn meal, bone meal, cereal meal, algae, fresh meat, meat meal, etc. can be used as raw materials. The mold can be changed for specific product shapes. The puffing machine adopts both dry and wet methods

4. conveyor: Transport the product to the oven, and the height of the elevator is determined based on the oven. The conveyor is an air blower, PVC elevator, and stainless steel elevator.

5. Multi layer oven: used to dry and dehydrate semi-finished products produced, using a belt drying device with a certain number of heating devices installed inside the oven. It is a commonly used drying and dehydration device for puffed products. Using electricity, gas, fuel oil, steam, hot air stove, heating for drying. The temperature is adjustable between -220 degrees Celsius through the control cabinet, and the interior is made of stainless steel. The baking time can be adjusted according to the speed of the three layer, five layer, and seven layer stainless steel ovens.

6 Seasoning Line: There are octagonal tube, single drum, double drum seasoning lines, and double head automatic octagonal tube seasoning machines, which are configured according to the output and product properties.

7. Cooling machine: used for product cooling and easy packaging, single layer cooling and multi-layer cooling machines. Configure different cooling machines according to production capacity.

8. Packaging machine: used for product packaging, different packaging machines are selected according to the packaging type: fully automatic packaging machine, quantitative packaging machine, etc.