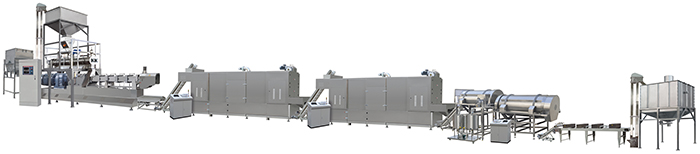

pet food production line

pet food production line is designed reasonably and got high degree of automation. It can control the extrusion technological parameters precisely. The conditioner is designed innovative, two axle different running speed, Enhanced condition, condition time 180 seconds, further improving the aging effect. The screw innovative design, increases the sue for range of the materials, improves product quality and increase the type of products. Advanced cutting structure and device.

Many kinds of grain, meat meal, fish meal, beans can be used for this line to make dog food, cat food etc. By adjusting raw material proportion, temperature, moisture technological parameter, you can have the products get the rich nutrition, cured well, structure refined, suitable for tastes and nutritional requirements of dog or cat.

Process flow Pet food production line:

Raw material preparation →mixing → conveying → extrusion →conveying → drying → oil spraying → seasoning → cooling → screening → packaging

Feature

1.This Pet Food Processing Machine is researched for pet feed market.

2.Good waterproof, long floating time, also can add microelement to promote the growth of pet fish, which is very popular in the aquaculture industry.

3.Production line with full automatic and high capacity, is a good choice for different market from different area.

4. main motor brand is SIEMENS.

5. Relay: ABB or customized.

6. Inverter ( used to control the speed of the main motor , feeding system and cutting system ) brand can be Delta, Pioneer, CHNT or Schneider.

7. All the electric device brand can be customized as you need.

8. Dyer & baking machine source can be designed use Electricity, Gas, Oil or stream.

9. Machine material generally is Food grade stainless steel, also can customized as require.

10. Guarantee Time is 2 year.

11. After-sales Service Provided: Free spare parts, Field installation, Commissioning and training, Field maintenance and repair service, Video technical support, Online support.

Application

Parameter

Model parameter | DS65 pet food production line

| DS70 pet food production line

| DS75 pet food production line

| DS85 pet food production line

| DS95 pet food production line

| DS100 pet food production line

| DS140 pet food production line

|

Installed power | 80kw | 90kw | 118kw | 160kw | 200kw | 300kw | 400kw |

Power consumption | 60kw | 70kw | 88kw | 112kw | 140kw | 150kw | 200kw |

output | 100-200kg/h | 180-250kg/h | 200-350kg/h | 600-800kg/h | 1500-1800kg/h | 1500-1800kg/h | 1200-2000kg/h |

cover an area | 80 m² | 80 m² | 120 m² | 150 m² | 180 m² | 180 m² | 220 m² |

Water consumption | ≤30kg/h | ≤60kg/h | ≤60kg/h | ≤100kg/h | ≤200kg/h | ≤200kg/h | ≤400kg/h |

operator | 2-3 persons | 2-3 persons | 2-3 persons | 2-3 persons | 2-3 persons | 2-3 persons | 2-3 persons |

生产流程 Process | 配料→混料→挤压膨化制粒→筛选→烘干→喷涂→冷却→成品 Ingredients → Mixing → Extrusion → Drying→ Spray seasoning (optional) → packing | ||||||

适用原料 Applicable materials | Corn flour, rice flour, bone flout, animal fat etc | ||||||

主要材质Material | 喂料系统及外壳采用304不锈钢材质;机架及部分零配件采用碳钢材质;螺杆及刀具采用高强度合金钢材质 The feeding system and surface are made of SS304; The shelf and some parts are made of carbon steel; The screw and knife are made of high-strength alloy steel material | ||||||

温控方式 Temperature control method | 电加热/蒸汽加热;水冷却(选配) Electric heating/steam heating; Water cooling (optional) | ||||||

控制方式 Control method | 独立电控柜操控;变频调速 Independent electric control cabinet control; inverter control | ||||||