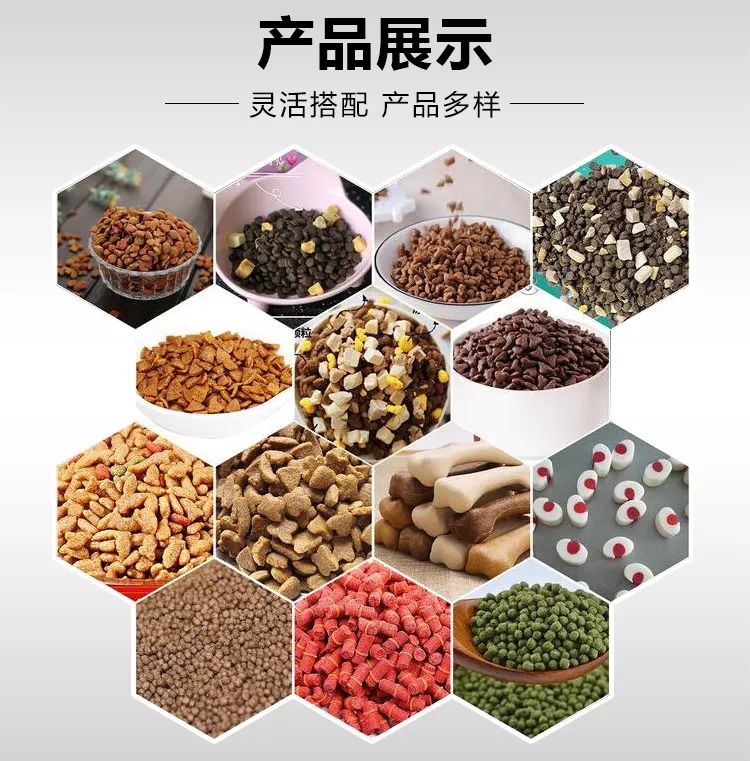

pet food extruder characteristics

pet feed extruder characteristics

pet feed extruder capacity is 2500kg/h, and the wear life is more than 20,000 tons. The good combination of gearbox and barrel screw can ensure 24-hour non-stop production. The feeding method of the extruder adopts the disc as the arch-breaking feeder, and the feeding is uniform and stable. The modulator uses a single-axis pre-conditioner and a dual-axis pre-conditioner, which has good modulation effect and high degree of ripening. The pre-conditioner is specially equipped with the function of adding fresh meat, function to realize the production function of fresh meat dog food.

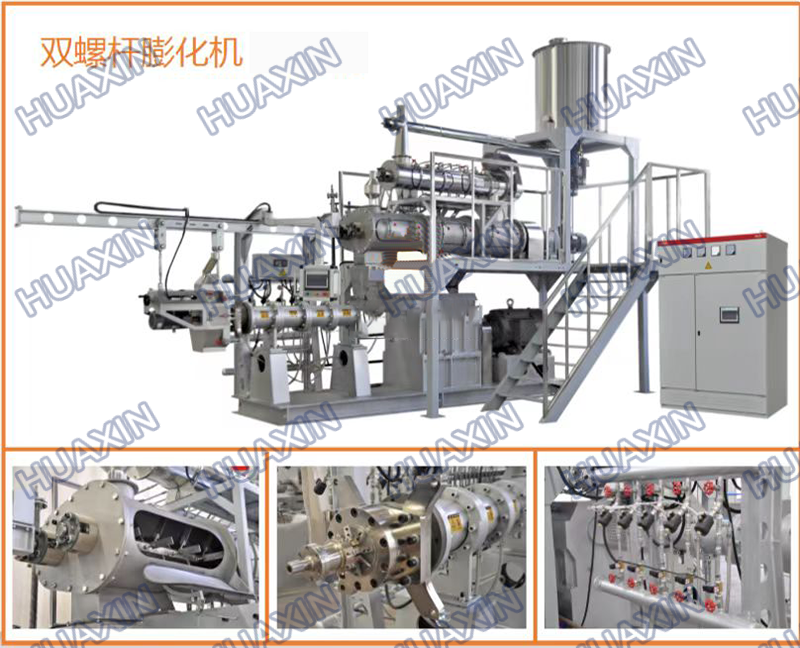

Twin-screw extruder: the main motor is equipped with 110kw, inverter speed regulation.

Series of Double Screw Extruder mainly consist of feeding system, extruding system, cutting system, heating system, lubricating system and controlling system.

The gearbox uses NSK bearings, which have a long service life, Direct coupling between motor and gearbox, reducing energy consumption.

The barrel uses a 45 steel round barrel inlaid with an alloy bushing.

The length-diameter ratio of the screw is 19.5. The overall use of combination screw, double-ended thread, material 38CrMnoAl. Double screws feed equal materials forcibly.

The production capacity is 2500kg/h, and the wear life is more than 20,000 tons. The good combination of gearbox and barrel screw can ensure 24-hour non-stop production. The feeding method of the extruder adopts the disc as the arch-breaking feeder, and the feeding is uniform and stable. The modulator uses a single-axis pre-conditioner and a dual-axis pre-conditioner, which has good modulation effect and high degree of ripening. The pre-conditioner is specially equipped with the function of adding fresh meat, function to realize the production function of fresh meat dog food.

The extruder uses PLC automatic control to control the barrel temperature and other motor parameters. The steam and water addition of the modulator is divided into manual control and automatic control. The automatic control addition can realize the free setting of parameters through the proportional control valve, which is similar to the 5-10 ton extruder.

Feeding, cutting and main extruding drive all adopt inverter control with strong power, stable performance and low consumption.

Automatic lubricating and forced cooling make sure that extruder performs safely and extends using life.

By means of designing different structures and slenderness ratios according to needs of products, screw extruding system can meet different technology demands.