Talk about the types of puffing food machinery and the correct operation methods

Talk about the types of puffing food machinery and the correct operation methods

With grains, beans, potatoes and other products as raw materials, they are processed by expanded food machinery, and have a wide variety of products, which are popular with everyone. The products made from different raw materials have different characteristics, and the puffed food machinery also has different types. When we choose to use them, we should choose according to our own needs. Next, let's learn about the types of expanded food machinery and the correct operation methods.

Types of puffed food machinery

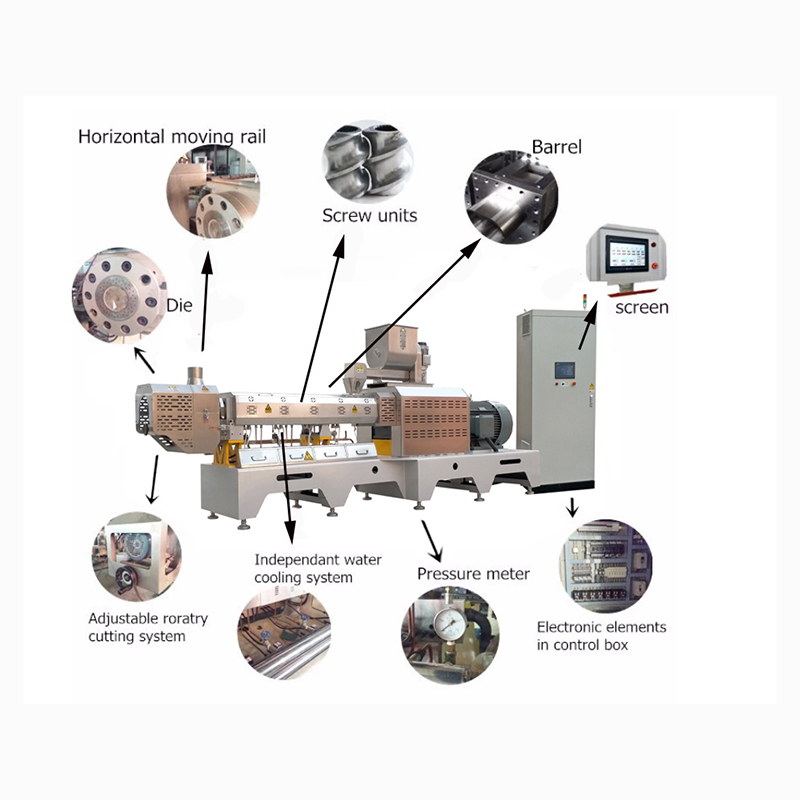

Due to different uses and equipment, puffed food equipment has the following three types: first, the extrusion machine is used to produce snacks with corn and potatoes as raw materials; second, the soya protein food (plant meat) is produced with plant protein as raw material using an extrusion extruder; Third, cereals, beans or potatoes are used as raw materials to make staple food after being expanded.

Correct operation method of expanded food machinery

1. When the screw is found to be blocked, do not stop the machine immediately, run it for a while after stopping feeding until there is a smell of burnt. This can prevent the nmould and screw from biting. In case that the nozzle and spiral shaft sleeve cannot be removed due to seizure, do not hit them hard, but remove them from the machine body and put them in the fire for a while before removing them.

2. In the early stage of operation, if the formed products cannot be sprayed out of the orifice, it is often caused by the high temperature of the nozzle, which is caused by too dry raw materials, or foreign matters in the screw, or the interruption of feeding. The causes should be found according to different conditions, and the fault should be eliminated.

3. After the operation is completed and the feeding is stopped, let the machine idle for one minute, discharge the materials in the machine and then stop the machine.

4. Before operation, remove the machine head, screw and other working parts, carefully clean mould and screw.

5. When using, start the machine and run for 1-2 minutes, then slowly add the raw materials to the feeding port. When about a handful of raw materials can fill the ring groove of the spiral shaft head, stop feeding and conduct friction preheating. When the temperature of the standby head rises, the pressure in the machine cavity increases, and the orifice starts to spray, feed again. Since the temperature and pressure in the machine cavity have not reached normal at this time, the feeding amount should be gradually increased.

6. The feeding shall be continuous and even, and the materials shall be dry, otherwise the screw may be blocked.

The above is about puffed food machine product and I hope it will be helpful to you.

Our company is mainly engaged in twin screw extruder, single screw extruder, dryer, roast oven, fryer, flavoring line, pet food production line, fish feed processing line, puff snacks/core filled snacks production line, artificial rice production line, fortified rice machine, corn flakes production line, breakfast cereal production line, bread crumb production line, nutritional powder/ baby food production line, corn chips/bugles production line, TVP/TSP/Meat Analogue production line, Soya protein processing line, vegetarian meat production line, 2D/3D pellet chips production line, modified starch/ pregelatinized starch production line, kurkure/ cheetos production line, rice crackers/ biscuit production line, instant noodles production line. Tortilla corn chips production line, which are professional and reliable. Welcome to visit the factory.