The characteristics of twin-screw extruder

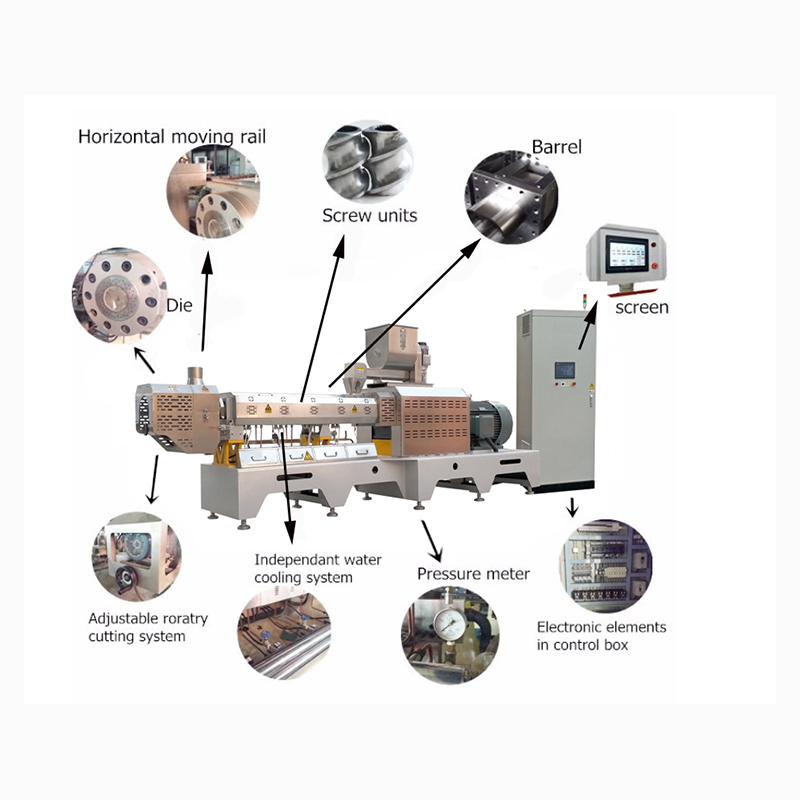

Twin-screw extruder is an automatic feeding machine. Twin-screw extruder is an instrument that integrates the physical steps of melt conveying, solid conveying, melting, pressurization, exhaust, dehumidification and so on into the extruder screw. Compared with single-screw extruder, twin-screw extruder is favored for its ability to mix melt more fully. At present, twin-screw extruder is mainly used for extruding products. To purchase a twin-screw extruder, it is necessary to pay attention to the acceptable price range, the processing accuracy of the equipment design, and whether the processing requirements are met. Different models of twin-screw extruders have different performance, different application occasions and different price ranges.

The accuracy of secondary processing mainly depends on the processing accuracy and processing accuracy. The parallelism of the lead screw mandrel determines the clearance between the screw edge and the inner wall of the cylinder, as well as the clearance in the meshing area, so it is very important. Secondly, the carburization depth between the inner wall of the cylinder and the screw surface determines the service life of the screw.

What are the advantages of using twin-screw granulator? It can improve efficiency and reduce costs, and also effectively realize the processing of various materials. The following series will introduce you in detail.

1. The automatic twin-screw granulator can effectively improve the efficiency of material processing and molding. The number of operating buttons is small, improving efficiency and reducing costs. At the same time, during the maintenance process, its own turbine case handle decoration can quickly open the cylinder for maintenance. Therefore, this reliable twin-screw granulator can be used for maintenance, reducing the time required for maintenance and daily processing.

The twin-screw extruder can effectively realize the processing of various materials according to the characteristics of engineering plastic materials?? The production of flexible particles is its own high-quality function, while the current high-quality twin-screw granulator has the adaptability of a variety of materials, and can have more stable processing quality and efficient production response in use.

3 Operation should be standardized. The twin-screw granulator has good quality and excellent service. The relevant operation will be described in detail. Each step is closely linked and will be clearly and effectively explained in the specific use training.

Our company is mainly engaged in twin screw extruder, single screw extruder, dryer, roast oven, fryer, flavoring line, pet food production line, fish feed processing line, puff snacks/core filled snacks production line, artificial rice production line, fortified rice machine, corn flakes production line, breakfast cereal production line, bread crumb production line, nutritional powder/ baby food production line, corn chips/bugles production line, TVP/TSP/Meat Analogue production line, Soya protein processing line, vegetarian meat production line, 2D/3D pellet chips production line, modified starch/ pregelatinized starch production line, kurkure/ cheetos production line, rice crackers/ biscuit production line, instant noodles production line. Tortilla corn chips production line, which are professional and reliable. Welcome to visit the factory.