The puffed food produced by extruder is healthy

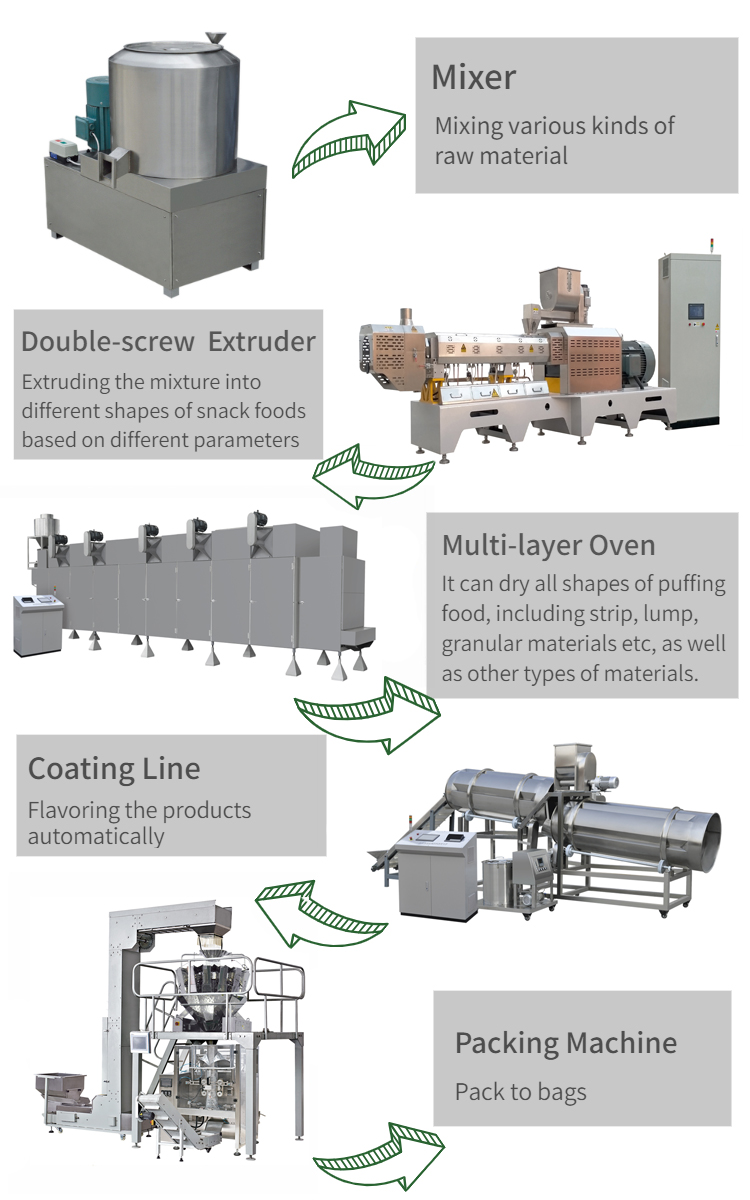

The puffing food machinery is fully automated from mixing, extrusion, extruding, forming, cutting, spraying to the finished product in one time. This production line has the characteristics of multiple optional models, flexible equipment configuration, wide range of raw materials, multiple product types, and simple operation. Choosing the appropriate configuration can produce products such as core filling snack, cereal, corn flakes, braised wheat, crispy rice, baby food, modified starch, etc., suitable for various food manufacturers.

According to the processing technology, puffed food machinery can be divided into roasting type, frying type, direct extrusion type, and pattern type.

1. Baking type. It is made by baking or frying and puffing, commonly including Snow Cake and candy craker.

2. Fried type. It is made by frying, commonly including fried potato chips, corn chips, etc.

3. Direct extrusion type. The raw material is extruded by an extruder and expanded under high temperature and pressure conditions using the pressure difference inside and outside the machine. Common ones include snack, cereals, Shrimp Strips, etc.

4. Colorful craftsmanship. On the basis of the above three processes, add another coloring process. core filling snack.

In addition to the traditional puffing technologies mentioned above, there have been many new puffing technologies in recent years. For example, vacuum low-temperature puffing technology is mainly used for puffing fruit and vegetable products. Microwave puffing technology is mainly used for cereal puffed products, such as popcorn and soybean products.

Expanding is just a food processing technique. Expanded foods is healthy.