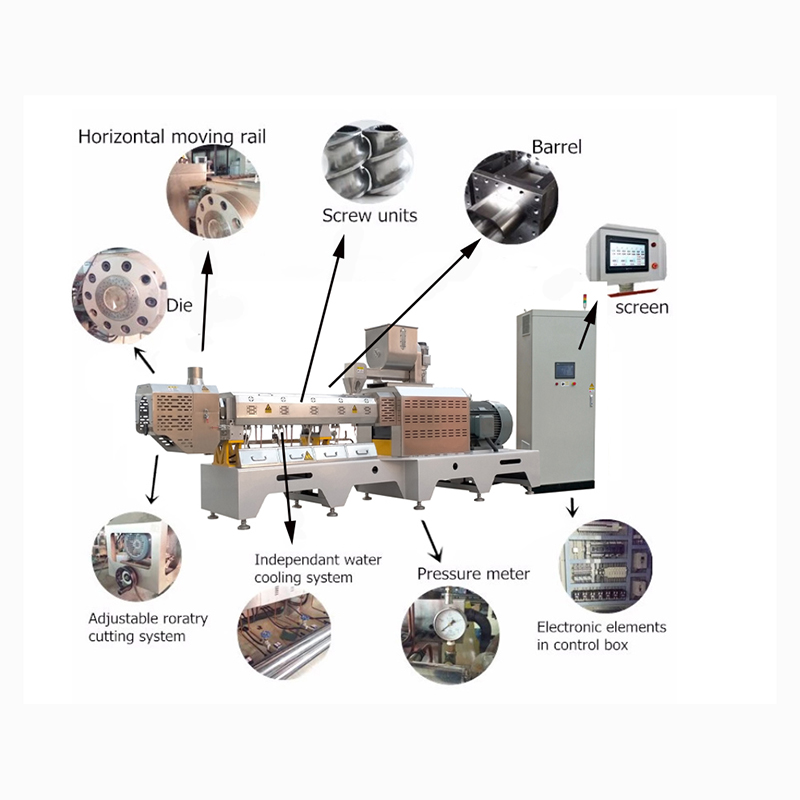

Twin screw extruder

Twin screw extruder is an automated production equipment widely used in grain deep processing, food production and processing, and feed production and processing, which can achieve puffing and ripening processing of various grains; Compared to traditional equipment such as steaming, frying, baking, etc., it has significant advantages such as high automation, long service life, large output, low energy consumption, and high cost-effectiveness. Its main products include grain meal replacement food/beverages, snack puffed food, instant rice, brushed protein, pet feed, pre gelatinized starch, etc.

Product advantages and features:

Advanced modular screw; Composed of various specifications of screw sleeves and core shafts, made of high-strength alloy material with a hardness of 63HRC, the service life can reach 10000 hours; Install different specifications of screw sleeves such as pressure boosting screws, pressure relief screws, shear blocks, resistance rings, etc. according to different product requirements.

Segmented square extruder barrel; Composed of a carbon steel barrel body and A101 high-strength alloy liner; Each section of the barrel has a reciprocating U-shaped waterway inside, and is equipped with a cast aluminum heating plate on the outside to achieve segmented precise temperature control, with a temperature control accuracy of ± 2 °.

Using well-known brands such as Siemens Beide motors, coupled with a dedicated power distribution box for the model, to efficiently transmit power to the screw; The distribution box adopts a lubricating oil immersion structure combined with an independent radiator, which can meet at least 72 hours of non-stop operation.

Independent control cabinet, with optional button and touch screen operation modes; Can set and control operating parameters such as screw speed, feeding speed, cutting speed, extrusion temperature, etc; All motor speeds are controlled by frequency conversion, and the temperature control part adopts PID control logic, which can achieve automatic temperature control.

Double helix feeding system, made of 304 stainless steel material, equipped with photoelectric limiters and organic glass visual windows, with uniform and smooth discharge, not easily blocked, and easy to clean; Can feed materials with different densities and viscosities.

The direct connected rotary cutting system, combined with customized molds, can produce products of different shapes and sizes; The cutting tool adopts a knob type adjustment, which is safe and fast. The rotary cutting cover is made of 304 stainless steel material and coated with PTFE to prevent sticking.