Twin screw extruder introduce and Characteristics

Twin screw extruder is a widely used production and processing equipment in the food and feed industries. Its suitable raw materials mainly include powder or grain grains, starch, and some animal fat. According to product requirements, multiple materials can also be mixed for use; This equipment uses twin screw extrusion to process the material under reasonable temperature, pressure, and cutting force, allowing the material to be extruded and shape through a mold. During this process, the material undergoes a series of physical and chemical changes such as expansion, and secondary shaping. Twin screw extruder products are widely used, mainly including casual puffed foods, breakfast cereal, soy protein, artificial rice, pet food, pre gelatinized modified starch, etc. With technological progress, more and more traditional production methods have been replaced by twin screw extrusion technology. Compared to food processing methods such as cooking, baking, and frying, its main advantages are high automation, multi-purpose machine Large single machine output and low energy consumption under the same output.

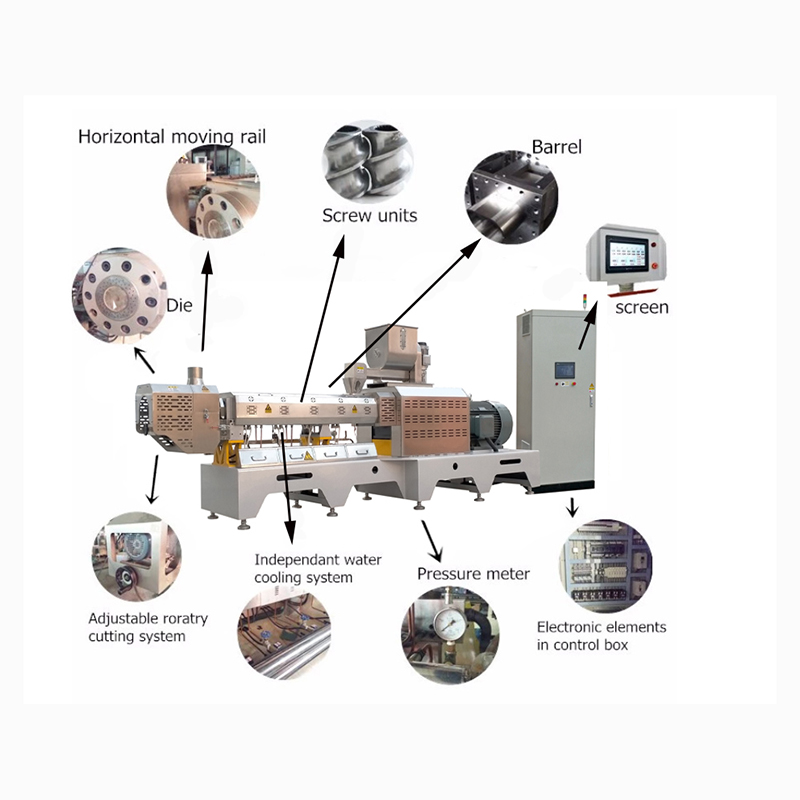

The twin screw extruder is mainly composed of six parts: extrusion system, electric control system, temperature control system, transmission system, feeding system, and shaping system; It can also be equipped with a vapor conditioning system for wet puffed production as needed. By designing different structures and slenderness ratios according to product needs, screw extrusion systems can meet different process requirements. In actual production, only the production parameters need to be set, and various systems automatically work together, with strong stability and reliable quality.

Characteristics of extruder:

Easy to use, stable transmission, and low noise.

The main components are made of special alloy materials through heat treatment, with a long service life.

The dry puffing process adopts self heating method and does not require a steam system, which is more in line with the practical needs of users.

The screw design has a strong self-cleaning function, and the screw groove can be self purified. Therefore, when changing the formula and product type, there is no need to stop for liquidation. The screw has a strong pumping effect, strong Diffusion effect of materials, fast propulsion speed, and relatively stable production and quality.

It can be equipped with an automatic feeding system, and the feeder is a new type of switch reluctance speed control motor in the world that controls the degree of feeding screw. The other end is connected to the expansion extruder, and the expansion output can be controlled by adjusting the feeding amount.

Cutting system, independent cutting installation and easy connection with the machine body, fast, variable speed cutting blade, can easily adjust the cutting blade, and adjust the gap between the cutting blade and the template. Different templates can be prepared according to needs, ensuring the required material diameter and length, and consuming products with different specifications and shapes.

parameter

型号 参数 | DS65 Extruder | DS70 Extruder | DS75 Extruder | DS80 Extruder | DS85 Extruder |

Screw diameter | 65mm | 70mm | 75mm | 80mm | 85mm |

Main motor power | 22kw | 30kw | 55kw | 75kw | 55-75kw |

output | 150kg/h | 250kg/h | 250 -350kg/h | 300-500kg/h | 300-500kg/h |

dimension | 2.7*0.9*1.9m | 3.6*0.9*1.9m | 4.9*1*1.9m | 4.9*1*1.9m | 5.8*1.2*2.5m |

Weight | 1500kg | 1600kg | 2800kg | 3000kg | 3000kg |

Material | The feeding system and surface are made of SS; The shelf and some parts are made of carbon steel; The screw and knife are made of high-strength alloy steel material | ||||

Temperature control method | Electric heating/steam heating; Water cooling (optional) | ||||

Control method | Independent electric control cabinet control; inverter control | ||||

Applicable raw materials | Corn flour, rice flour, flour and other powdered grains; Extracts from grains such as starch and wheat bran; Chicken, fish, pork | ||||

application | Cereal, puffed snacks, baby food, pre gelatinized modified starch, pet food, fish feed, etc | ||||