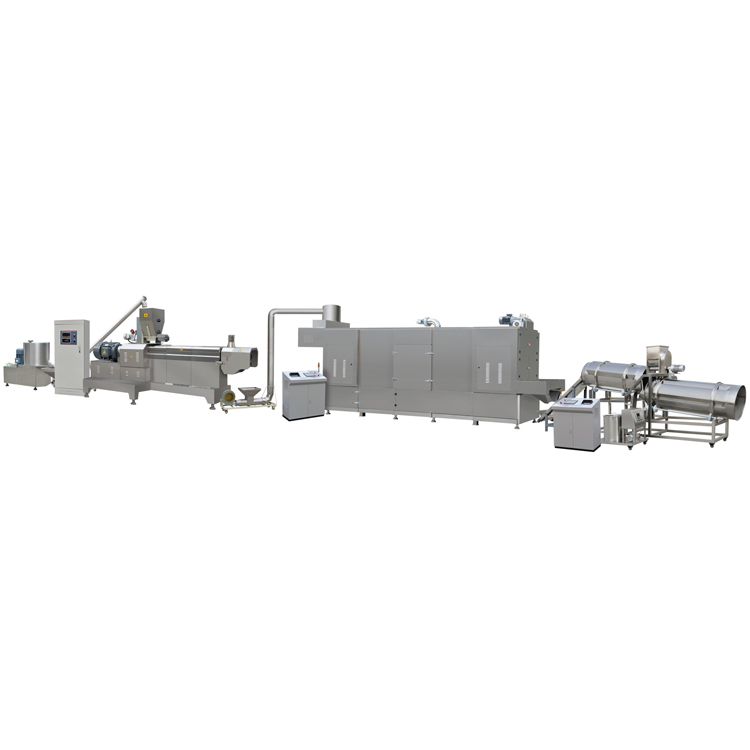

Corn Chips Snack Food Machine Production Line

- HXSD

- China

- 30 Days After Order

- 15 Set/month

corn chips snack food machine production line can be directly extruded from the extruder, dryer and flavoring machine. We can produce all kinds of snacks and different shapes by adjusting the dies from extruder. Corn Chips Snack Food Machine Production Line main motor brand is SIEMENS. Corn Chips Snack Food Machine Production Line Relay: ABB or customized. Corn chips snack food machine production line Inverter ( used to control the speed of the main motor , feeding system and cutting system ) brand can be Delta, Pioneer, CHNT or Schneider. Dyer & Baking Machine source can be designed use Electricity, Gas, Oil or stream.

Product Description:

corn chips snack food machine production line can be directly extruded from the extruder, dryer and flavoring machine. We can produce all kinds of snacks and different shapes by adjusting the dies from extruder. Corn Chips Snack Food Machine Production Line can take corn, rice, wheat, oat, and other grains as materials to produce extruded snacks, with crispy taste and lively shape, Corn Chips Snack Food Machine Production Line is designed according to market demand. It includes cheese balls, corn curls, corn sticks, coco pops, cereal, kurkure and pellets.

Corn Chips Snack Food Machine Production Line raw material:

corn flour ,rice flour ,wheat flour ,oat flour and so on as main raw material

Corn Chips Snack Food Machine Production Line Sample Show:

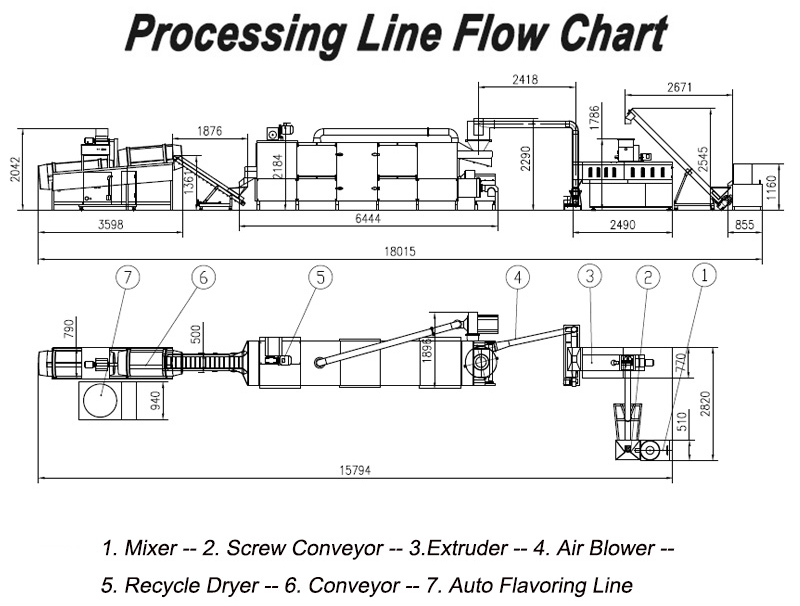

Corn Chips Snack Food Machine Production LineFlow Chart:

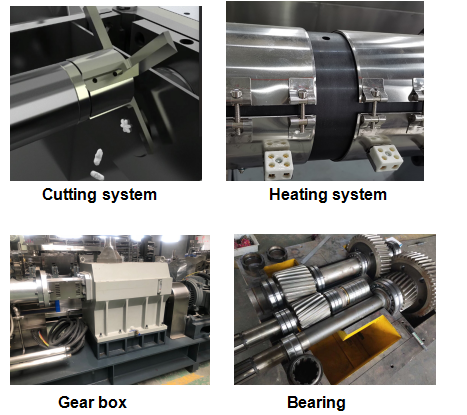

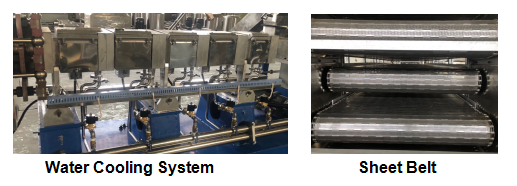

Corn Chips Snack Food Machine Production Line Main Details:

Mixer |

| Main structure: the flour mixer machine consists of a frame, transmission parts, mixer and cylinder parts. Using method: Put flour into the machine tube, turn on the motor, add other material, after mixing till your requirement, open the door, the powder will be push out by mixing wing. |

Extruder |

| 1.Extruder adopts the design of combined functional screws. The production parameters can be controlled automatically and accurately. 2. Feeding, main driving device, and rotary cutting device adopt inverter to adjust the speed with more powerful drive, stable running, and low consumption. 3. Screw is made of alloy steel with long life. 4 .Double-screw extruder can clean itself automatically. 5.special design of our gearbox by our company .long service life 6.The extruded producing is strength, toughness .And the shape is various ,it can be cylinder, flakes, rounded grain, square grain and so on. |

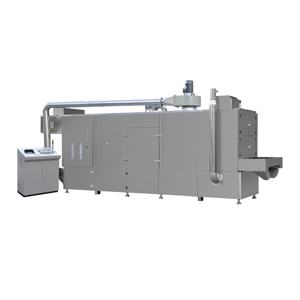

Oven |

| 1. Suitable to dry non-fried extrusion snacks. nutritional powder, bread crumb, pet food, textured protein, et 2.Heating source can be electric, gas, steam, fuel... |

Flavoring |  | 1. This flavoring line consist of hoister, flavoring drum, liquid spaying tank, spraying gun,etc. 2. The machine is made of stainless steel, complying with hygiene requirement. The control panel is easy to operate. Whole machine is compact with good performance. |

Corn Chips Snack Food Machine Production Line Technical Parameter:

Model | Output | power |

DS65 Chips Snack Food Production Line | 100-200kg/h | 80kw |

DS70 Chips Snack Food Production Line | 100-250kg/h | 90kw |

DS75 Chips Snack Food Production Line | 200-350kg/h | 100kw |

DS85 Chips Snack Food Production Line | 300-500kg/h | 120kw |

DS100 Chips Snack Food Production Line | 700-1000kg/h | 150kw |

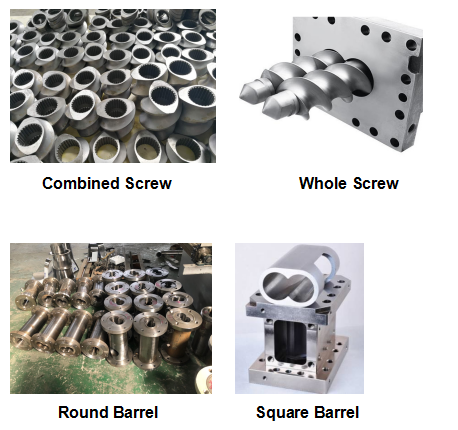

Main Accessories:

Company Information:

Our Advantages:

1. High qulity: Using high quality material and establishing a strict quality control system, assigning

specific persons in charge of each part of production, from raw material purchase to assembly.

2. Professional R&D center. Employed designers with 10 years working experience in food indus-

try. Each month will release a new senies of products. OEM and ODM are warmly welcomed.

3. In General, the delivery date will be 20 working days for normal buy quantity. But if bigger order,

please check us further.

4. Small order accepted: Low MOQ accepted 2pcs are available.

Factory:

Package & Shipping:

1).packaging: daub coal oil on the surface to protect the machine from moisture, Then cover with plastic film. Finaly pack them with wooden case.

2)Customer's requirement is available.

2).If you want to know the transportation cost: by air-please tell me your airport name; by express-please tell me your detailed address(including zip code,house number,street,city,country); by ship-pls tell me your delivery port.

FAQ

Q1. If machines wearing parts need changing, what should we do?

A1.We can offer the wearing parts all the time, and offer video.

Q2. What's the payment terms if we want to buy the machines?

A2.L/C, TT 30% down payment, 70% balance before delivery.

Q3.How about the delivery date?

A3: In General, the delivery date will be 20 working days for normal buy quantity. But if bigger order, please check us further.

Customers:

As a Chips Snack Food Production Line manufacturer, we have exported the Chips Snack Food Production Line to more than 80 countries and regions, such as South Africa, India, Malaysia, Indonesia, Brazil and so on. Some of customers become our agents in their area. We hope to have long friendly business relationship with more Chips Snack Food Production Line customers from all over the world in the future.

Our Services:

Q1. What's the pre-sale service of your company?

A1 Related machines' technical parameter will be supplied to customer.

1.1 According to customer's factory size, factory layout can be provided in advance.

1.2 According to customer's material cost, general formulation can be prepared well.

1.3Special machine can be supplied as customer's request.

1.4 Professional Advice about Market, machines, processing, materials, packing can be supplied.

1.5 Suggesting professional ship agent or helping book ship as customer request.

Q2. What's the after-sale service of your company?

A2.1Allocation chart as the buyer's request will be supplied.

2.2 Operation manual will be supplied after shipment.

2.3One year warrantee, life time maintenance with cost price.

2.4 Free easy broken spare parts will be sent with container .

2.5 First installation can be done by engineer.

2.6Training workers in customer's factory.

Exhibition review: