Corn Curls Cheese Ball Puff Snacks Processing Extruder

- HXSD

- China

- 30 Days After Order

- 15 Set/month

Corn Curls Cheese Ball Puff Snacks Processing Extruder is a new generation puffed food production equipment, developed by our company on the basis of absorbing foreign advanced technology of similar equipment. Corn Curls Cheese Ball Puff Snacks Processing Extruder main motor brand is SIEMENS. Corn Curls Cheese Ball Puff Snacks Processing Extruder Relay: ABB or customized. Corn Curls Cheese Ball Puff Snacks Processing Extruder Inverter ( used to control the speed of the main motor , feeding system and cutting system ) brand can be Delta, Pioneer, CHNT or Schneider. Baking Machine source can be designed use Electricity, Gas, Oil or stream. Machine material generally is Food grade stainless steel, also can customized as require.

Product Description:

Corn Curls Cheese Ball Puff Snacks Processing Extruder is a new generation puffed food production equipment, developed by our company on the basis of absorbing foreign advanced technology of similar equipment. Its technical performance and product quality have reached the advanced level of similar foreign equipment. The production line is from feeding materials, extruding, Forming, drying, oil spraying to finished products are done once time fully automatically.

Corn Curls Cheese Ball Puff Snacks Processing Extruder can produce different product (puff snacks, corn flakes, breakfast cereal, cheese ball, Bread crumbs)

Corn Curls Cheese Ball Puff Snacks raw material:

adopts corn, rice, wheat, oat, barley etc as ingredients

Corn Curls Cheese Ball Puff Snacks Processing Extruder Sample Show:

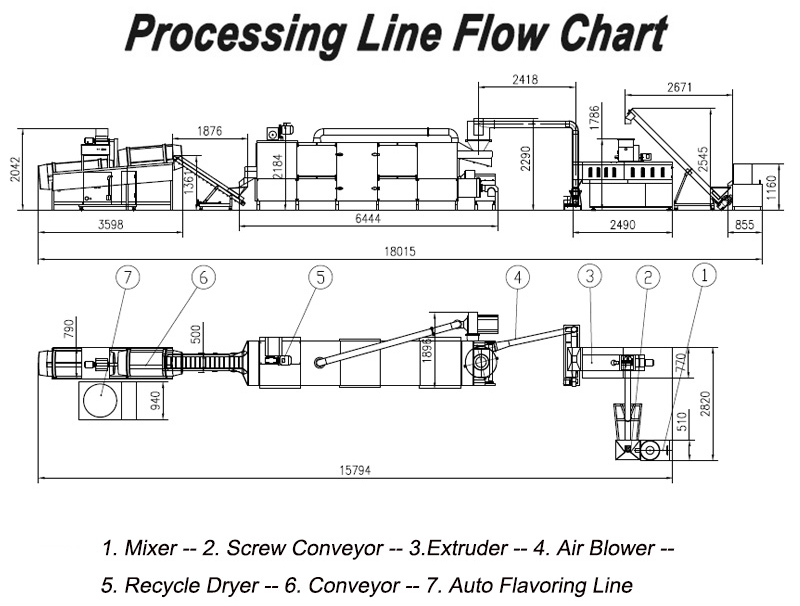

Corn Curls Cheese Ball Puff Snacks Processing Extruder Flow Chart:

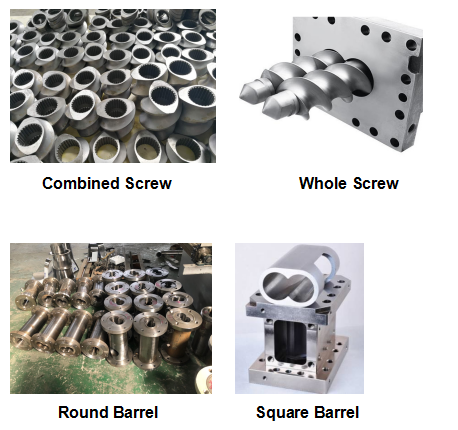

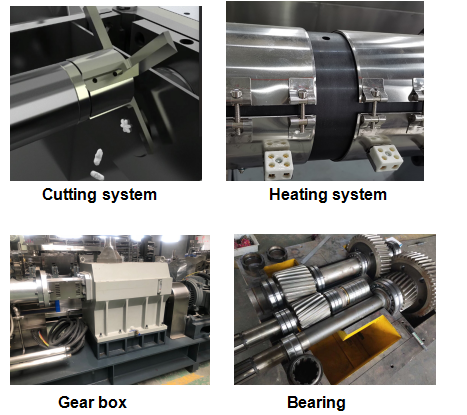

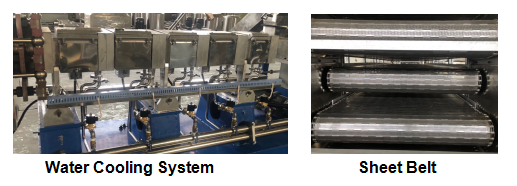

Corn Curls Cheese Ball Puff Snacks Processing Extruder Main Details:

Mixer |

| Adopted the speed reducer motor connected directly with the mixing wings, then bring the mixing blade high efficiency take rounds to mix the flour flakes material inside of mixer. |

Extruder |

| 1). Twin screw extruder are made of feeding system, extrusion system, cutting system, heating system, lubrication system, and control system. |

Oven |

| 1. Heating source can be electric, gas, steam, fuel... 2. Hot wind cycle device makes heat energy equal every layer of fryer 3. Adjustable transit speed of conveyor belt with accurate temperature control device, Mesh belt is stainless steel material. 4. Double-roller chain and chain drive make stable and smooth running 5. Sliding board bottom of dryer for easy cleaning 6. Suitable to dry non-fried extrusion snacks. nutritional powder, bread crumb, pet food, textured protein, et |

Flavoring |  | 1. This flavoring line consist of hoister, flavoring drum, liquid spaying tank, spraying gun,etc. 2.The machine is made of stainless steel, complying with hygiene requirement. The control panel is easy to operate. Whole machine is compact with good performance. |

Corn Curls Cheese Ball Puff Snacks Processing Extruder Technical Parameter:

Model | Output | power |

DS65 Corn Curls Cheese Ball Puff Snacks Processing Extruder | 100-200kg/h | 80kw |

DS70 Corn Curls Cheese Ball Puff Snacks Processing Extruder | 100-250kg/h | 90kw |

DS75 Corn Curls Cheese Ball Puff Snacks Processing Extruder | 200-350kg/h | 100kw |

DS85 Corn Curls Cheese Ball Puff Snacks Processing Extruder | 300-500kg/h | 120kw |

DS100 Corn Curls Cheese Ball Puff Snacks Processing Extruder | 700-1000kg/h | 150kw |

Main Accessories:

Company Information:

Our Advantages:

1. High qulity: Using high quality material and establishing a strict quality control system, assigning

specific persons in charge of each part of production, from raw material purchase to assembly.

2. Professional R&D center. Employed designers with 10 years working experience in food indus-

try. Each month will release a new senies of products. OEM and ODM are warmly welcomed.

3. In General, the delivery date will be 20 working days for normal buy quantity. But if bigger order,

please check us further.

4. Small order accepted: Low MOQ accepted 2pcs are available.

Factory:

Package & Shipping:

1).packaging: daub coal oil on the surface to protect the machine from moisture, Then cover with plastic film.Finaly pack them with wooden case.

2)Customer's requirement is available.

2).If you want to know the transportation cost: by air-please tell me your airport name; by express-please tell me your detailed address(including zip code,house number,street,city,country); by ship-pls tell me your delivery port.

FAQ

Q1. What's the pre-sale service of your company?

A1 Related machines' technical parameter will be supplied to customer.

1.1 According to customer's factory size, factory layout can be provided in advance.

1.2 According to customer's material cost, general formulation can be prepared well.

1.3Special machine can be supplied as customer's request.

1.4 Professional Advice about Market, machines, processing, materials, packing can be supplied.

1.5 Suggesting professional ship agent or helping book ship as customer request.

Q2. What's the after-sale service of your company?

A2.1Allocation chart as the buyer's request will be supplied.

2.2 Operation manual will be supplied after shipment.

2.3One year warrantee, life time maintenance with cost price.

2.4 Free easy broken spare parts will be sent with container .

2.5 First installation can be done by engineer.

2.6Training workers in customer's factory.

Q3. If machines wearing parts need changing, what should we do?

A3.We can offer the wearing parts all the time, and offer video.

Q4. What's the payment terms if we want to buy the machines?

A4.L/C, TT 30% down payment, 70% balance before delivery.

Q5: How about the delivery date?

A5: In General, the delivery date will be 20 working days for normal buy quantity. But if bigger order, please check us further.

Q6: How about the label and the logo?

A6: Customize label and logo is workable.

Customers:

As Corn Curls Cheese Ball Puff Snacks Processing Extruder manufacturer, we have exported the Corn Curls Cheese Ball Puff Snacks Processing Extruder to more than 80 countries and regions, such as South Africa, India, Malaysia, Indonesia, Brazil and so on. Some of customers become our agents in their area.

Our Services:

About installation and after-sale service system

1. We can provide factory layout according to customer’s factory size in advance.

2. When we received your deposit of this order, we will ask our engineers to prepare to apply the visa, when the processing line arrived your country,

and we will send two engineers to go and help you to install the line, teach your worker(3-4 workers) how to operate the line, until your worker know the 3D line well.

3. Our engineers has responsibility to teach your worker how to clean the extruder, how to change the screw, how to change barrel etc.

and we have responsibility to provide technology support with you forever.

4. Our engineers can provide basic formula for producing the snack food etc. and help customer to produce good quality food according customer’s detailed formula.

5. We provide the spare parts will at preferential price for an extended long time.

6. other item:

a). Free consultation service before, during, and after sales;

b). Free project planning and design services;

c). Free debugging of equipment until everything is functional;

d). Free management of equipments' long distance shipping;

e). Free training of equipment maintenance and operating personally;

f). Free new production techniques and formulas;

g). Provide 1 year complete warrantee and life-time maintance service;

Exhibition review:

Finally, sincerely welcome you to our factory, you will know our machines and factory strength better after your visit, you would have a worthy business trip!!!