Floating Fish Feed Pet Food Pellet Machine Processing Plant

Floating Fish Feed Pet Food Pellet Machine Processing Plant is researched for fish feed market. Good waterproof, long floating time, also can add microelement to promote the growth of pet fish, which is very popular in the aquaculture industry. Floating Fish Feed Pet Food Pellet Machine Processing Plant with full automatic and high capacity, is a good choice for different market from different area. Main motor brand is SIEMENS. Floating Fish Feed Pet Food Pellet Machine Processing Plant Inverter ( used to control the speed of the main motor , feeding system and cutting system ) brand can be Delta, Pioneer, CHNT or Schneider. Dyer & baking machine source can be designed use Electricity, Gas, Oil or stream. Machine material generally is Food grade stainless steel, also can customized as require.

Product Description:

Floating Fish Feed Pet Food Pellet Machine Processing Plant is designed reasonably and got high degree of automation. It can control the extrusion technological parameters precisely. The conditioner is designed innovative, two axle different running speed, Enhanced condition, condition time 180 seconds, further improving the aging effect. The screw innovative design, increases the sue for range of the materials, improves product quality and increase the type of products. Advanced cutting structure and device.

Raw material:

Corn flour, wheat flour, chicken powder, fish powder, soybean, bone powder etc.

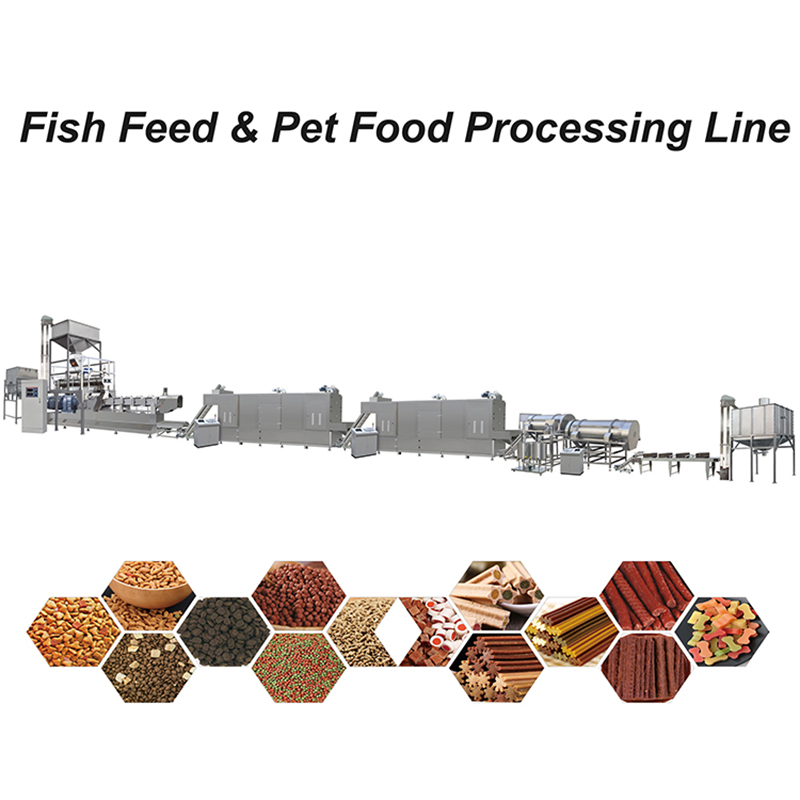

Floating Fish Feed Pet Food Pellet Machine Processing Plant Sample Show:

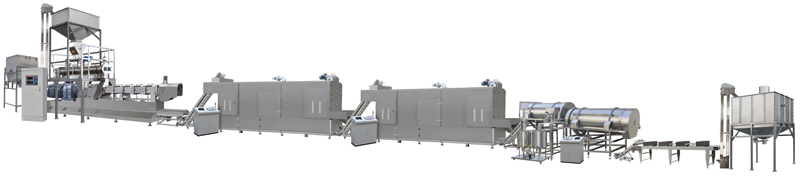

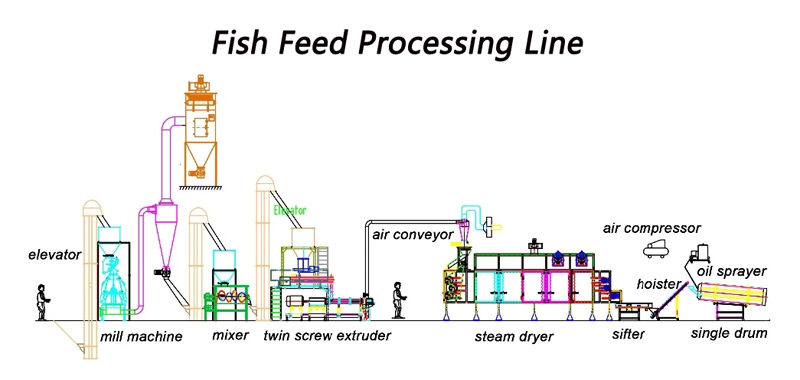

Floating Fish Feed Pet Food Pellet Machine Processing Plant Flow Chart:

Floating Fish Feed Pet Food Pellet Machine Technical Parameter:

Model parameter | DS65 Floating Fish Feed Pet Food Pellet Machine | DS75 Floating Fish Feed Pet Food Pellet Machine | DS85 Floating Fish Feed Pet Food Pellet Machine | DS100 Floating Fish Feed Pet Food Pellet Machine |

Installed power | 80kw | 118kw | 160kw | 200kw |

Power consumption | 60kw | 88kw | 112kw | 140kw |

Output | 100-200kg/h | 200-400kg/h | 600-800kg/h | 1500-1800kg/h |

length | 22m | 28m | 35m | 40m |

Floating Fish Feed Pet Food Pellet Machine Main Details:

Blender | | Mix the powder ingredients and water in proportion to the formula. High speed mixing, high mixing efficiency, high mixing uniformity, no dust mixing process. Adopted the speed reducer motor connected directly with the mixing wings, then bring the mixing blade high efficiency take rounds to mix the flour flakes material inside of mixer. Equipped with the high precision reducer to avoid motor burn out and longer the motor service life |

Vacuum Transporter |

| The feeding speed is fast and the continuous working time is long.

|

Pre-conditioner |

| The tempering device is a material that enters the tempering device with steam or sprayed water, and is uniformly mixed by high-speed stirring. The whole process is continuous and smooth without leakage, no dust, can replace the powder mixer and has high production efficiency and many functions. Features: 1. All parts in contact with the material are made of stainless steel; 2. Using imported nozzles, all the required water enters the conditioner in a mist; 3. The amount of water can be adjusted steplessly at any time to meet the requirements of different processes and different raw materials; 4. The conditioner can be filled with water or steamed for a wider range of applications. |

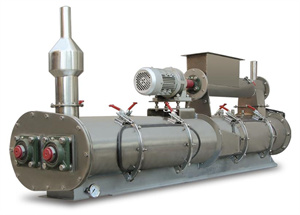

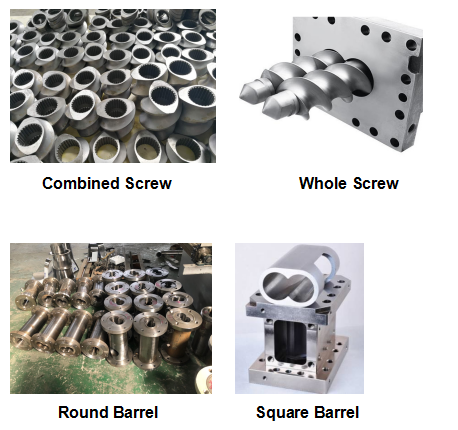

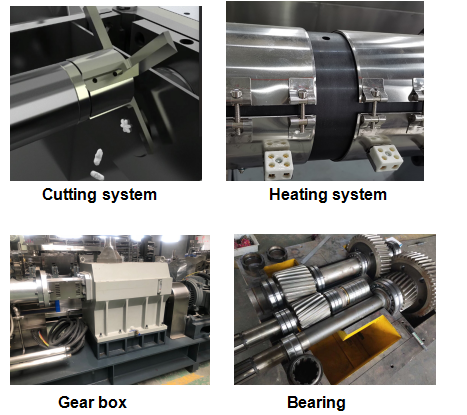

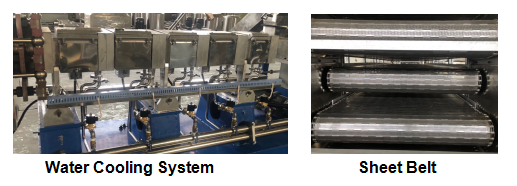

Double SCREW Extruder | | 1. Extruder adopts the design of combined functional screws. The production parameters can be controlled automatically and accurately. 2. Feeding, main driving device, and rotary cutting device adopt inverter to adjust the speed with more powerful drive, stable running, and low consumption. 3. Screw is made of alloy steel with long life. 5.special design of our gearbox by our company .long service life |

Air Blower |

| The main function of air conveyor is to transmit material from upper level machine to next level machine. It contains air blower, feeding cone and air pipe etc, it is an equipment with multipurpose function, it can work under many snack food production line. Motor:2840RPM |

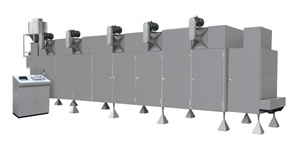

Dryer

| | These series of roasting oven are widely used, it is used for drying all kinds of stick, piece, grain etc. puffed snacks, nutritional powder, bread crumb, pet food, textured vegetarian protein etc. the user can choose different layer, length of dryer according to different product. The whole machine is compact design, logical and easy operation. Driving system adopts double pitch roller chain driving, circulating drying, and balanced running, never jam. Drying temperature and time can be adjusted, effect of drying is capitally. With high efficiency fuel saving system, reasonable heat distribution, material be heated equally, low energy but large output. sliding board bottom of dryer for easy cleaning. |

Vibrator/ Material Distributor | | Through shaking method spread materials evenly to flavoring line , and separating unsatisfied products. |

Auto Flavoring Line |

| According to the type of products and output into a single drum and double drum, three drums. The double drum is used to spray oil at the feed first. And then the seasoning are sprinkled on the surface, suitable for production of high - grade products. |

Automatic Packing Machine | | Combination head weigher Vertical automatic packing machine . we have model 420, 520, 620 and 720 vertical packing machine. Which is chosen according to the weight of your packing bags and shape. Together with packing machine, air compressor, nitrogen system is also optional according to your basic requirements. |

Main Accessories:

Company Information:

Our Advantages:

1. High qulity: Using high quality material and establishing a strict quality control system, assigning specific persons in charge of each part of production, from raw material purchase to assembly.

2. Professional R&D center. Employed designers with 10 years working experience in food indus- try. Each month will release a new senies of products. OEM and ODM are warmly welcomed.

3. In General, the delivery date will be 20 working days for normal buy quantity. But if bigger order, please check us further.

4. Small order accepted: Low MOQ accepted 2pcs are available.

Factory:

Package & Shipping:

Inside package is plastic film, outside is wooden or plywood case

(based on the customers' need).

1. Only plastic film nude packing with wooden pallet.

2. We can supply fumigation package and certificate.

3. Shipping, train, express or upon clients' demands.

FAQ

Q1. What's the pre-sale service of your company?

Related machines' technical parameter will be supplied to customer.

1.1 According to customer's factory size, factory layout can be provided in advance.

1.2 According to customer's material cost, general formulation can be prepared well.

1.3 Special machine can be supplied as customer's request.

1.4 Professional Advice about Market, machines, processing, materials, packing can be supplied.

1.5 Suggesting professional ship agent or helping book ship as customer request.

Q2. What's the after-sale service of your company?

2.1 Allocation chart as the buyer's request will be supplied.

2.2 Operation manual will be supplied after shipment.

2.3 One year warrantee, life time maintenance with cost price.

2.4 Free easy broken spare parts will be sent with container .

2.5 First installation can be done by engineer.

2.6 Training workers in customer's factory.

Q3. If machines wearing parts need changing, what should we do?

A3. We can offer the wearing parts all the time, and offer video.

Q4. What's the payment terms if we want to buy the machines?

A4. L/C, TT 30% down payment, 70% balance before delivery.

Customers:

As Floating Fish Feed Pet Food Pellet Machine Processing Plant manufacturer, we have exported the Floating Fish Feed Pet Food Pellet Machine Processing Plant to more than 80 countries and regions, such as South Africa, India, Malaysia, Indonesia, Brazil and so on. Some of customers become our agents in their area. We hope to have long friendly business relationship with more Floating Fish Feed Pet Food Pellet Machine Processing Plant customers from all over the world in the future.

Our Services:

About installation and after-sale service system

1. We can provide factory layout according to customer’s factory size in advance.

2. When we received your deposit of this order, we will ask our engineers to prepare to apply the visa, when the processing line arrived your country,

and we will send two engineers to go and help you to install the line, teach your worker(3-4 workers) how to operate the line, until your worker know the 3D line well.

3. Our engineers has responsibility to teach your worker how to clean the extruder, how to change the screw, how to change barrel etc.

and we have responsibility to provide technology support with you forever.

4. Our engineers can provide basic formula for producing the snack food etc. and help customer to produce good quality food according customer’s detailed formula.

5. We provide the spare parts will at preferential price for an extended long time.

6. other item:

a). Free consultation service before, during, and after sales;

b). Free project planning and design services;

c). Free debugging of equipment until everything is functional;

d). Free management of equipments' long distance shipping;

e). Free training of equipment maintenance and operating personally;

f). Free new production techniques and formulas;

g). Provide 1 year complete warrantee and life-time maintance service;

Exhibition Review: