Pasta Production Machine

Pasta Production Machine is produced by extruder through extruding cooking; the pellet can be different shapes like shell, spiral, square tube, circle tube, and so on. After drying, the pellet needs frying to get expanded.

Features:

1. It have full-automatic and semi-automatic commercial pasta making machines

2. Original : wheat flour potato starch, corn starch, cassava starch, , etc.

3. It can process various materials, widely applied in many industries: macaroni/ pasta baby rice powder, sesame paste, and nut paste food etc.

4. We can provide special design according to clients requirements.

5. Inverter control,good stability,centralized control,easy operation , large output and short time,save cost etc

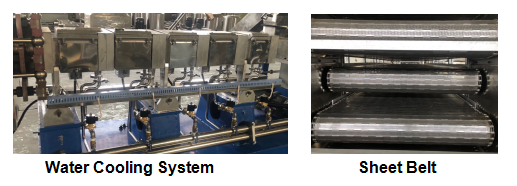

Pasta Production Machine Flow chart: Mixing system---Extrusion system----Cutting system---Drying system---Cooling system

Pasta Production Machine raw materials: adopts potato starch, corn starch, cassava starch, wheat flour, corn flour etc as raw materials

Pasta Production Machine Sample Show:

Pasta Production Machine Products: can be used to produce Shell, spiral, square tube, circle tube shapes

Pasta Production Machine Technical Parameter:

Model | Output | Power |

3000-100 Pasta Production Machine | 80-120kg/h | 78Kw |

3000-130 Pasta Production Machine | 180-250kg/h | 110kw |

Pasta Production Machine Main Details:

Vacuum Transporter |

| The feeding speed is fast and the continuous working time is long.

|

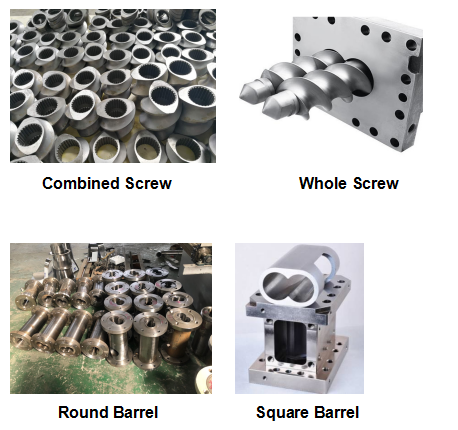

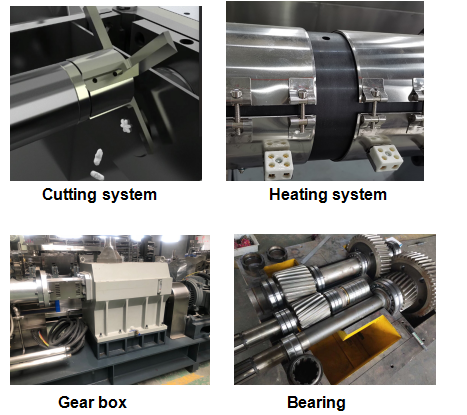

Double SCREW Extruder | | 1. Extruder adopts the design of combined functional screws. The production parameters can be controlled automatically and accurately. 2. Feeding, main driving device, and rotary cutting device adopt inverter to adjust the speed with more powerful drive, stable running, and low consumption. 3. Screw is made of alloy steel with long life. |

Main Accessories:

Company Information:

Factory:

Package & Shipping:

Inside package is plastic film, outside is wooden or plywood case

(based on the customers' need).

1. Only plastic film nude packing with wooden pallet.

2. We can supply fumigation package and certificate.

3. Shipping, train, express or upon clients' demands.

FAQ

Q1. What's the pre-sale service of your company?

Related machines' technical parameter will be supplied to customer.

1.1 According to customer's factory size, factory layout can be provided in advance.

1.2 According to customer's material cost, general formulation can be prepared well.

1.3 Special machine can be supplied as customer's request.

1.4 Professional Advice about Market, machines, processing, materials, packing can be supplied.

1.5 Suggesting professional ship agent or helping book ship as customer request.

Q2. What's the after-sale service of your company?

2.1 Allocation chart as the buyer's request will be supplied.

2.2 Operation manual will be supplied after shipment.

2.3 One year warrantee, life time maintenance with cost price.

2.4 Free easy broken spare parts will be sent with container .

2.5 First installation can be done by engineer.

2.6 Training workers in customer's factory.

Q3. If machines wearing parts need changing, what should we do?

A3. We can offer the wearing parts all the time, and offer video.

Q4. What's the payment terms if we want to buy the machines?

A4. L/C, TT 30% down payment, 70% balance before delivery.