Pellet Chips Snacks Food Production Line

- HXSD

- China

- 30 Days After Order

- 15 Set/month

Pellet Chips Snacks Food Production Line main motor brand is SIEMENS. Pellet Chips Snacks Food Production Line Relay: ABB or customized. Dyer & Baking Machine source can be designed use Electricity, Gas, Oil or stream. Machine material generally is Food grade stainless steel, also can customized as require.

Product Description:

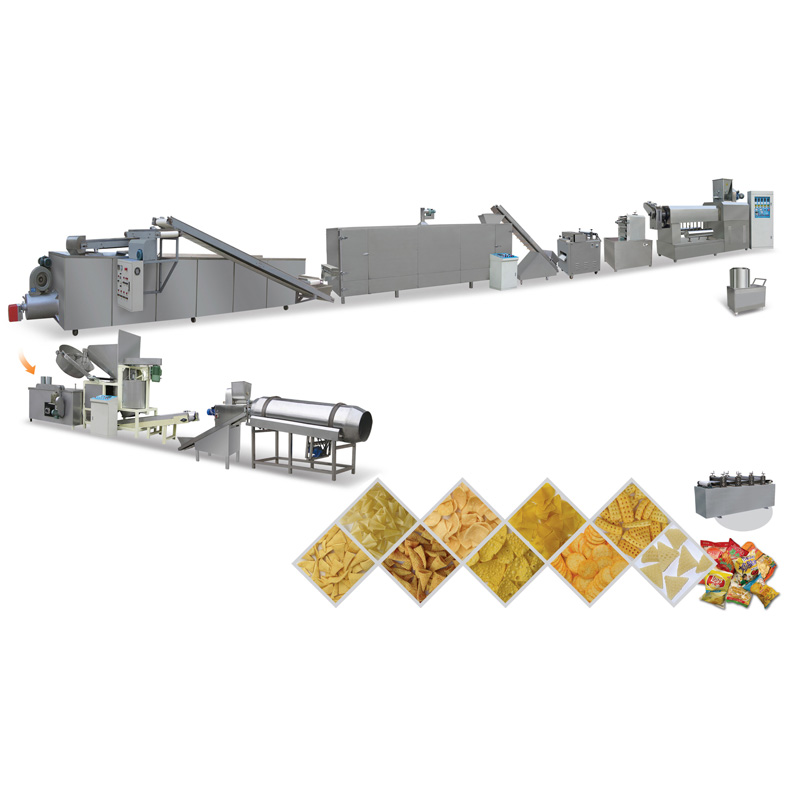

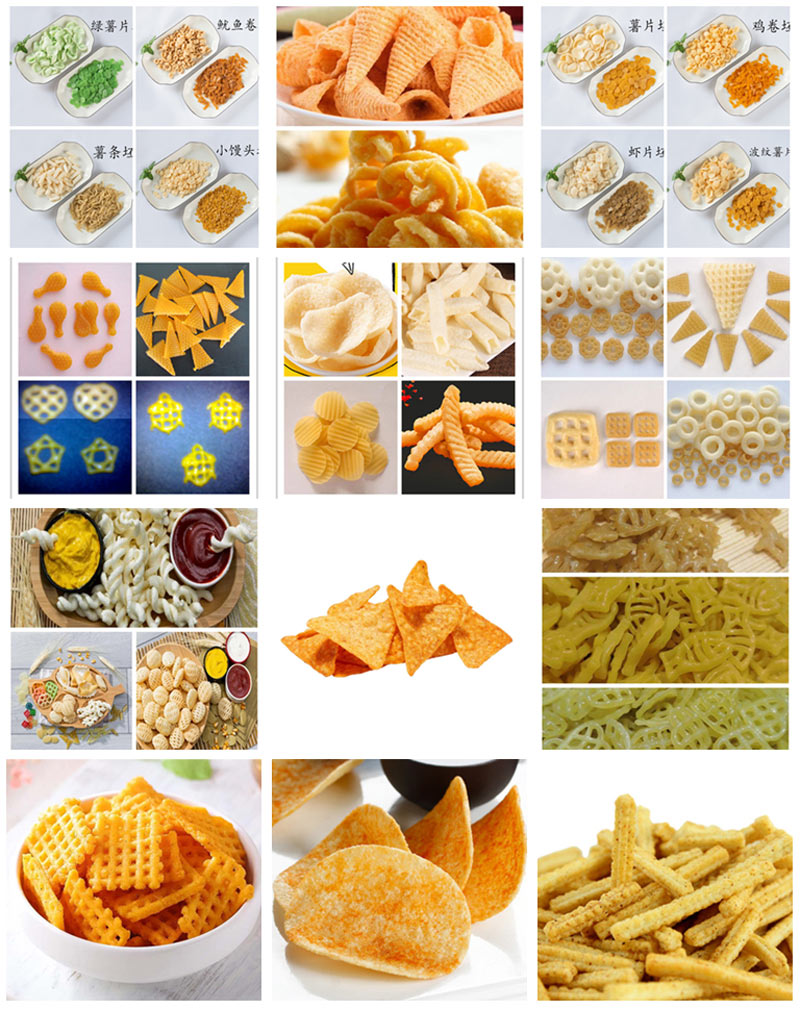

Pellet Chips Snacks Food Production Line production line can make different kinds of fried snacks (such as rice crusts, chips, bulges, pizza rolls, Doritos) by changing the moulds and manufacturing technique. The products making by Pellet Chips Snacks Food Production Line are in the following flavors: Chile Cheese, Nacho cheese, Original, Sour cream and Onion, Salsa, BBQ. The name comes from their shape.

Raw material for Pellet Chips Snacks Food Production Line:

Potato starch, corn starch, cassava starch, wheat flour, corn flour etc.

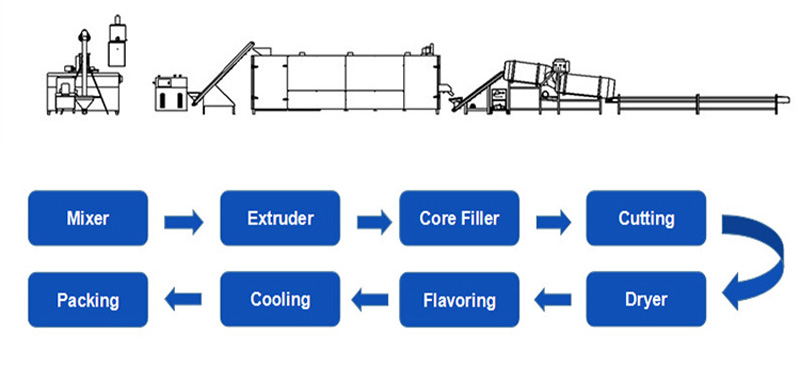

Pellet Chips Snacks Food Production Line Flow Chart:

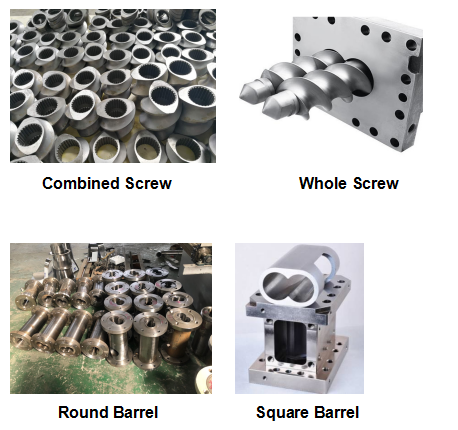

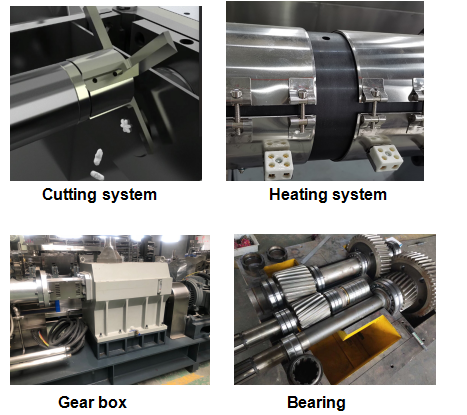

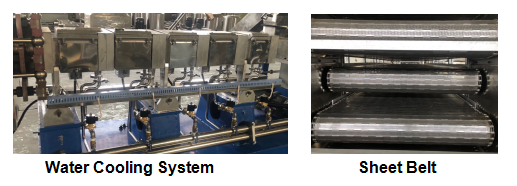

Pellet Chips Snacks Food Production Line Main Details:

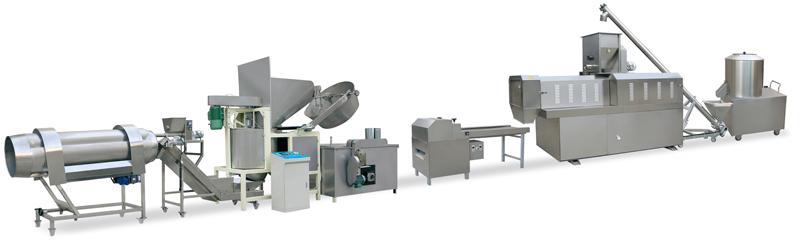

Mixer |

| Adopted the speed reducer motor connected directly with the mixing wings, then bring the mixing blade high efficiency take rounds to mix the flour flakes material inside of mixer. |

Extruder |

| 1.Extruder adopts the design of combined functional screws. The production parameters can be controlled automatically and accurately. 2. Feeding, main driving device, and rotary cutting device adopt inverter to adjust the speed with more powerful drive, stable running, and low consumption. 3. Screw is made of alloy steel with long life. 4 .Double-screw extruder can clean itself automatically. 5.special design of gearbox has long service life |

Mutifunction Nacho/ Doritos Chips /Tortilla Chips Shaper |  | |

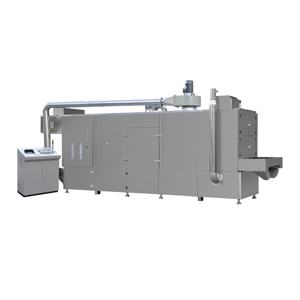

Oven |

| 1. Heating source can be electric, gas, steam, fuel... 2. Hot wind cycle device makes heat energy equal every layer of oven 3. Adjustable transit speed of conveyor belt with accurate temperature control device, Mesh belt is stainless steel material. 4. Double-roller chain and chain drive make stable and smooth running 5. Sliding board bottom of dryer for easy cleaning 6. Suitable to dry non-fried extrusion snacks. nutritional powder, bread crumb, pet food, textured protein, etc |

Automatic Continous frying system |  | Including: Auto elevator’ Auto feeding belt Smart temperature system Smart Auto oil feeding system Material belt |

Flavoring |  | Including the flavor sprayer, Belt conveyor and rotary machine. |

Pellet Chips Snacks Food Production Line Technical Parameter:

Model | DS65 Pellet Chips Snacks Food Production Line | DS75 Pellet Chips Snacks Food Production Line | DS85 Pellet Chips Snacks Food Production Line |

power | 80kw | 100kw | 120kw |

Output | 100-200kg/h | 200-350kg/h | 350-500kg/h |

Main Accessories:

Company Information:

Our Advantages:

1. High qulity: Using high quality material and establishing a strict quality control system, assigning specific persons in charge of each part of production, from raw material purchase to assembly.

2. Professional R&D center. Employed designers with 10 years working experience in food indus- try. Each month will release a new senies of products. OEM and ODM are warmly welcomed.

3. In General, the delivery date will be 20 working days for normal buy quantity. But if bigger order, please check us further.

Factory:

Package & Shipping:

Inside package is plastic film, outside is wooden or plywood case

(based on the customers' need).

1. Only plastic film nude packing with wooden pallet.

2. We can supply fumigation package and certificate.

3. Shipping, train, express or upon clients' demands.

FAQ

Q1. What's the pre-sale service of your company?

Related machines' technical parameter will be supplied to customer.

1.1 According to customer's factory size, factory layout can be provided in advance.

1.2 According to customer's material cost, general formulation can be prepared well.

1.3 Special machine can be supplied as customer's request.

1.4 Professional Advice about Market, machines, processing, materials, packing can be supplied.

1.5 Suggesting professional ship agent or helping book ship as customer request.

Q2. What's the after-sale service of your company?

2.1 Allocation chart as the buyer's request will be supplied.

2.2 Operation manual will be supplied after shipment.

2.3 One year warrantee, life time maintenance with cost price.

2.4 Free easy broken spare parts will be sent with container .

2.5 First installation can be done by engineer.

2.6 Training workers in customer's factory.

Q3. If machines wearing parts need changing, what should we do?

A3. We can offer the wearing parts all the time, and offer video.

Q4. What's the payment terms if we want to buy the machines?

A4. L/C, TT 30% down payment, 70% balance before delivery.

Customers:

As Pellet Chips Snacks Food Production Line manufacturer, we have exported the Pellet Chips Snacks Food Production Line to more than 80 countries and regions, such as South Africa, India, Malaysia, Indonesia, Brazil and so on. Some of customers become our agents in their area. We hope to have long friendly business relationship with more Pellet Chips Snacks Food Production Line customers from all over the world in the future.

Service and Training:

Services and Upgrades:We offer turnkey projects and can comprehensively upgrade all or part of your existing equipment.

Maintenance and Repair:Work with our experienced engineers to maintain your equipment.

Consultation and Training:We provide pre-production consulting and post-production worker training, as well as customised technical training.

Exhibition Review: