Configuration and process composition of modified starch production line

Modified starch production equipment is a mechanical equipment that performs secondary processing of starch and utilizes physicochemical or enzymatic processing to change the properties of starch. The purpose of starch denaturation is to meet the needs of various industrial applications. With the development of science and technology, the production equipment of modified starch has also made great progress. Next, let's learn about the configuration and process composition of the modified starch production equipment production line.

1. Equipment configuration of modified starch production line:

Screw conveyor → Mixer →Screw conveyor →Twin screw extruder → Cooling conveyor → Wet mill → Air blower → Auto continuous belt oven →Screw conveyor → Ultrafine pulverizer → Packaging

2. Process composition of modified starch production line

Mixer: Mix starch (corn starch, cassava starch, potato starch, etc.) alone or with some additives, add some water, and fully stir evenly.

Feeding machine: The motor is used as the power for screw conveying to convey the mixed raw materials to the feeding hopper of the extruder, ensuring convenient and fast feeding.

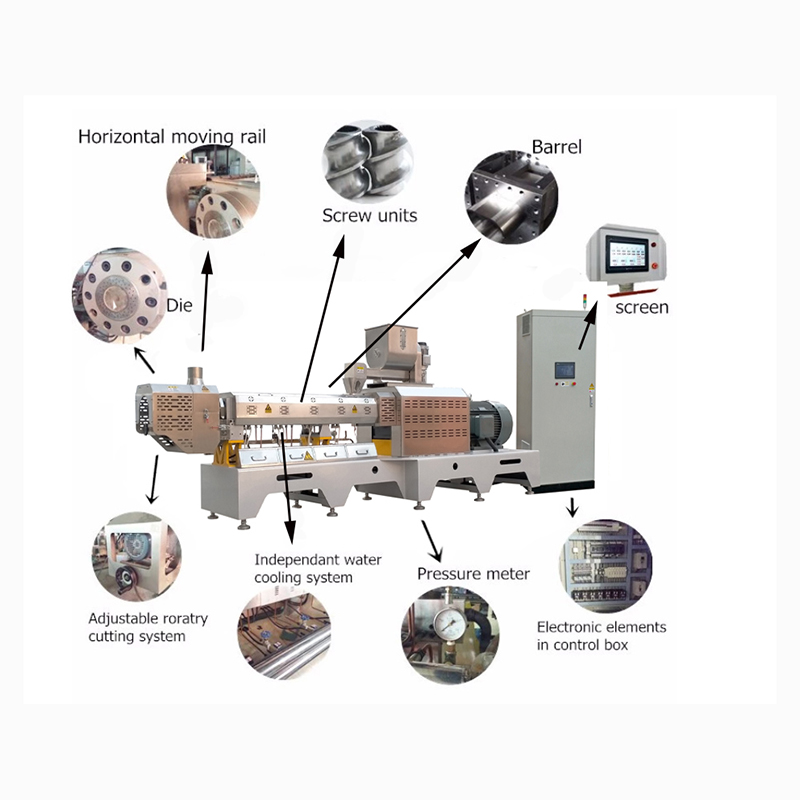

Extruder: high-strength European standard integrated frame, practical and beautiful; Servo degree European standard integrated rack, practical and beautiful; The assembled barrel and assembled screw structure can be combined according to the needs of experimental technology, practical and convenient, with strong material applicability. The barrel and screw material are made of special steel, which is wear-resistant and corrosion resistant; The compact integrated vacuum exhaust cooling system uses famous brand components, featuring high reliability and low noise; Humanized structure design, SIEMENS PLC touch screen, more convenient operation.

Air blower: Conveys particles to the oven, and the height of the elevator is determined based on the oven

Auto continuous belt oven: The oven is an electric oven, and the temperature is adjustable between 0-200 through the control cabinet

Ultrafine pulverizer: Different pulverizers are selected according to the requirements for modified starch

3. Performance characteristics of modified starch production equipment

The frequency converter speed regulation technology adopted by the host machine enables the equipment to have strong power, operate more smoothly and save electricity;

The screw adopts alloy steel nitriding treatment, with a longer service life. Individual equipment adopts a modular structure, which can be arbitrarily combined according to different needs;

Forced lubrication system to ensure longer service life of the transmission part of the equipment;

A fully automatic visual temperature control system makes temperature control more intuitive and parameters more accurate;

The screw has an automatic cleaning function, which eliminates the need to disassemble the screw for cleaning during shutdown;

Different screw and length to diameter ratio can meet different production processes;

The main components of the extruder assembly line are heavy processing equipment of the company, with stable quality, low cost, and preferential accessories;

After reading the above content, I believe everyone has a certain understanding of the modified starch production line. If you want to learn more about the relevant content, you can follow this website. Our company specializes in selling equipment such as modified starch production lines, tissue protein production lines, pet feed machinery, and twin screw extruder. Welcome to visit our factory for guidance.