Nutritional rice/ Artificial rice/ Fortified rice/ Golden rice scheme and production line

Nutritional rice production line is another innovative application of twin-screw technology. It can be completed from raw material processing, extrusion ripening, molding and drying at one time. It can also strengthen all kinds of vitamins and minerals necessary for human health in proportion to produce special nutritional fortified rice. This production technology can not only retain the original ingredients of ordinary rice, but also produce coarse grain and fine grain. With the improvement of people's living standards, People also have higher requirements for food on the table, and nutritious rice products highlight a good market prospect.

The processing technology of nutritious rice. First of all, when the twin-screw extruder extrudes the expanded food, it is necessary to crush the material with the size of 30-40 mesh, so that the material can be evenly mixed. Through extrusion and cooking, the starch can be fully gelatinized. Then condition the mixed materials, put the materials into the pre modulator, absorb water, gelatinize, etc., and extend the moisture shelf life. After baking, the food will produce fragrance, and the quality of food can be improved.

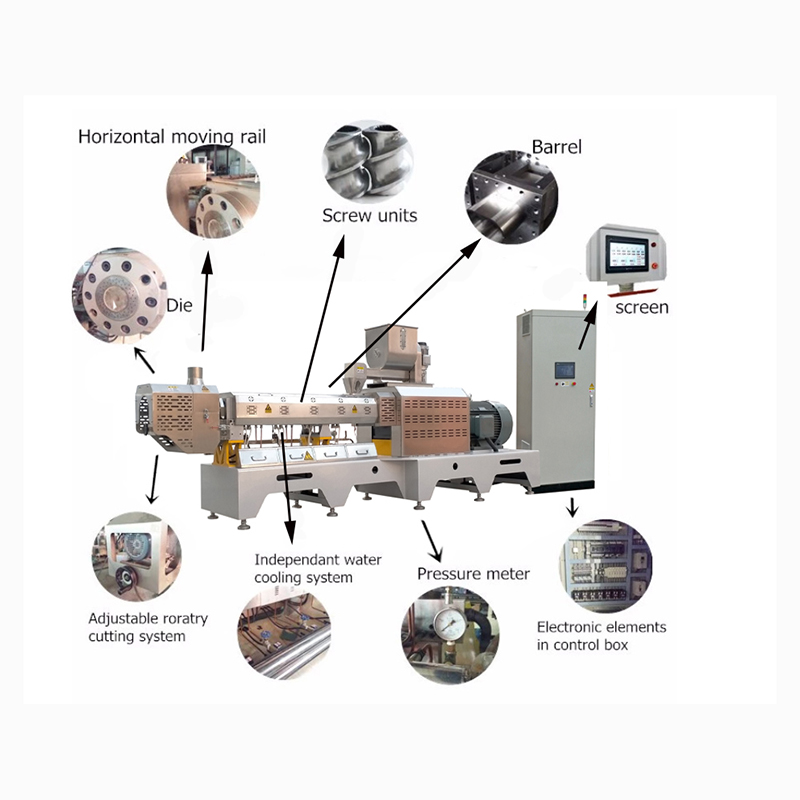

Processing principle of nutritious rice. It is necessary to put the raw materials into the extruder first. The raw materials move under the action of the screw and screw in the extruder, and friction occurs between materials, materials and barrel, screw, etc. The materials will be sheared, squeezed and stirred. The temperature inside the extruder will increase, and the pressure will increase. At high temperature and high pressure, the materials will become paste and better shaped.

Product line advantages

1. Productivity: continuous and automatic process start and fast stop, fast and simple conversion, and easy cleaning and maintenance efficiency

2. Support product innovation: used to process a variety of encouraging raw materials, sizes, shapes and fillers (with optional co-extrusion accessories)

3. Flexibility: It is only necessary to modify the module or add components to produce thin, two-color products, co-extruded grains with obvious contents or various shapes, so as to expand the product range.

4. Cost-effective: strengthen the high-temperature short-time conversion process and save raw materials, energy and water; Easy to maintain, sanitary design and compact design, requiring a small floor area.

5. Expert system: specially designed by our expert engineers, with advanced automation functions, which can ensure accurate process control to achieve consistent product quality that can be easily replicated.

6. Finished product capacity: 200kg/h to 800kg/h

7. Testing new formula and improving the processing process, ideas, product design, formula laboratory, prototype design, pre-industrial test and mass production can all be carried out independently and secretly in our factory, paying attention to people's consumption habits and lifestyle, to predict the breakfast trend, and regularly propose new product ideas to its customers

Our company is mainly engaged in twin screw extruder, single screw extruder, dryer, roast oven, fryer, flavoring line, pet food production line, fish feed processing line, puff snacks/core filled snacks production line, artificial rice production line, fortified rice machine, corn flakes production line, breakfast cereal production line, bread crumb production line, nutritional powder/ baby food production line, corn chips/bugles production line, TVP/TSP/Meat Analogue production line, Soya protein processing line, vegetarian meat production line, 2D/3D pellet chips production line, modified starch/ pregelatinized starch production line, kurkure/ cheetos production line, rice crackers/ biscuit production line, instant noodles production line. Tortilla corn chips production line, which are professional and reliable. Welcome to visit the factory.