Selection and development of puffing food machinery

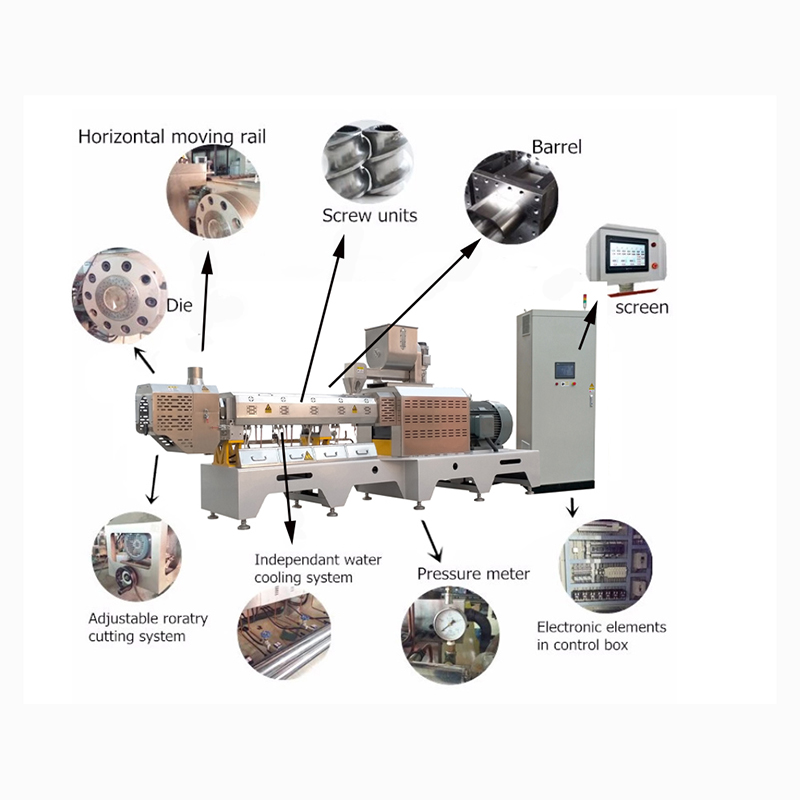

With the continuous development of the extruder, the production performance is continuously improved, the work quality is reliable, the failure rate is low, the operation and maintenance are convenient, and the economic benefits of the enterprise are effectively improved; In the continuous research, the production process of the extruder has been improved to make it have better operation methods and greatly improve the production efficiency; In the manufacturing process, the main components of the extruder are made of special alloy materials and heat treated, which have a good service life; The expansion machine adopts dry expansion process and self-heating method, which is more in line with the actual needs of users; The main parts of screw extruder have powerful self-cleaning function, reduce manual operation, and save a lot of labor costs for extruder enterprises.

Due to different uses and equipment, there are three types of puffed food:

The first is to use the extruder to produce small food with corn and potatoes as raw materials;

The second is to use the extruder to produce structured protein food with plant protein as raw material;

The third is to use grains, beans or potatoes as raw materials to expand into staple food. In addition to trial production of indirect heating puffer, refined grain puff powder was also used to test various puffed foods.

Working principle of puffing food machinery:

1. The working principle of the puffing food machine is also relatively simple. The puffing machine uses mechanical energy to convert heat energy to provide kinetic energy.

2. When the extruded food machinery materials are squeezed to the outlet, the pressure changes from high pressure to normal pressure, and from high temperature to normal temperature, resulting in the water quickly coming out of the organizational structure. With the friction between the screw and the bore, the materials are fully mixed, extruded, heated, glued, and pasted, resulting in the organizational change, the original structure is damaged, resulting in the formation of numerous microporous structures inside, and then through the cutting device, Cut and cool the extruded food to form.

3. The continuous volume of puffed food is pushed by the unequal distance non-standard spiral system of the puffer. The gas in the material is discharged and quickly filled by the material. The material is subject to the shear force to generate backflow, which increases the pressure in the chamber. At the same time, the mechanical energy is converted into heat energy through the friction of the material in the chamber, making the material become a gel state with flowing properties.

Repair and maintenance of expanded food machinery:

1. Extruded raw materials shall be cleaned to prevent metal and other foreign matters from entering the machine and damaging the machine parts;

2. It is strictly forbidden to use a hard hammer in the process of disassembly and assembly of screw, screw sleeve and other vulnerable parts, and it is strictly forbidden to place heavy objects or stand on the expansion cavity;

3. When the expansion materials are not used or replaced after long-term shutdown, the materials in the expansion cavity should be cleaned to avoid caking, mildew or cross contamination between materials;

Our company is mainly engaged in twin screw extruder, single screw extruder, dryer, roast oven, fryer, flavoring line, pet food production line, fish feed processing line, puff snacks/core filled snacks production line, artificial rice production line, fortified rice machine, corn flakes production line, breakfast cereal production line, bread crumb production line, nutritional powder/ baby food production line, corn chips/bugles production line, TVP/TSP/Meat Analogue production line, Soya protein processing line, vegetarian meat production line, 2D/3D pellet chips production line, modified starch/ pregelatinized starch production line, kurkure/ cheetos production line, rice crackers/ biscuit production line, instant noodles production line. Tortilla corn chips production line, which are professional and reliable. Welcome to visit the factory.