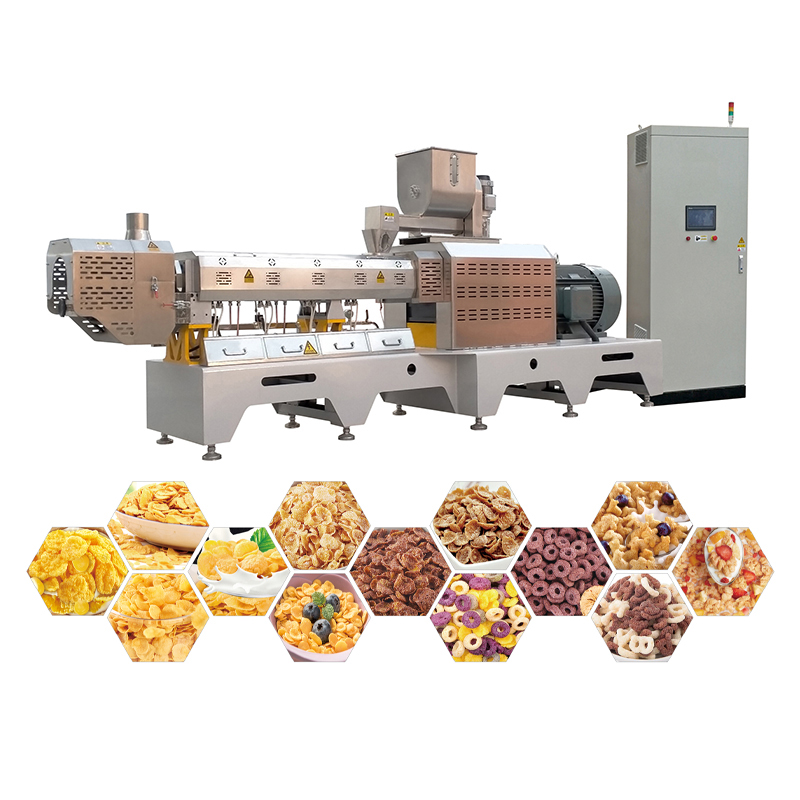

Automatic Breakfast Cereal Corn Flakes Processing Line

- HXSD

- China

- 30 Days After Order

- 15 Set/month

Automatic Breakfast Cereal Corn Flakes Processing Line main motor brand is SIEMENS. Automatic Breakfast Cereal Corn Flakes Processing Line Relay: ABB or customized. Automatic Breakfast Cereal Corn Flakes Processing Line Inverter can be Delta. Automatic Breakfast Cereal Corn Flakes Processing Line material generally is Food grade stainless steel, also can customized as require. All the electric device brand can be customized as you need. Baking Machine source can be designed use Electricity, Gas, Oil or stream.

Product Description:

Automatic Breakfast Cereal Corn Flakes Processing Line is improved and developed based on advanced technology by our company. Automatic Breakfast Cereal Corn Flakes Processing Line performance and products quality reach to the most advanced level in the world. Automatic Breakfast Cereal Corn Flakes Processing Line has features of flexible collocation, extensive applied raw materials, various snack and easy operation. It is full automatic from mixing, extruding, shaping, cutting, drying to flavoring in one-pass operation. By changing the moulds and process technology.

Breakfast Cereal Corn Flakes Sample Show:

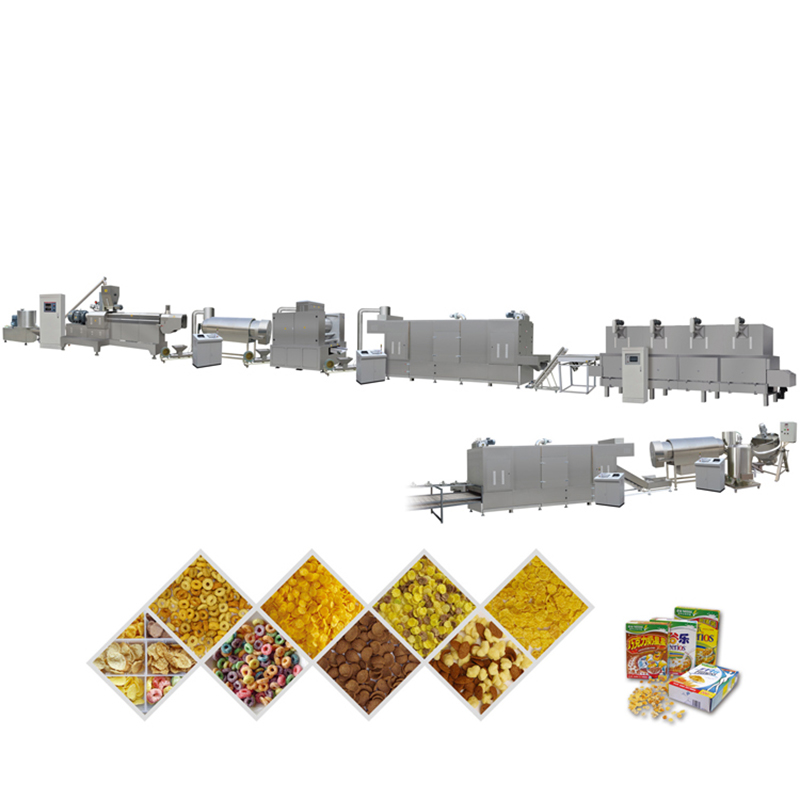

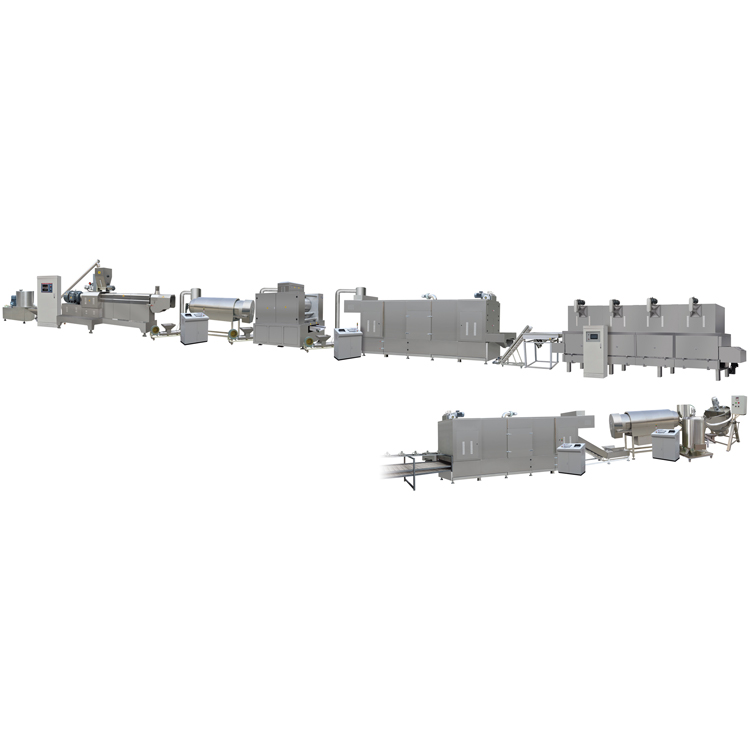

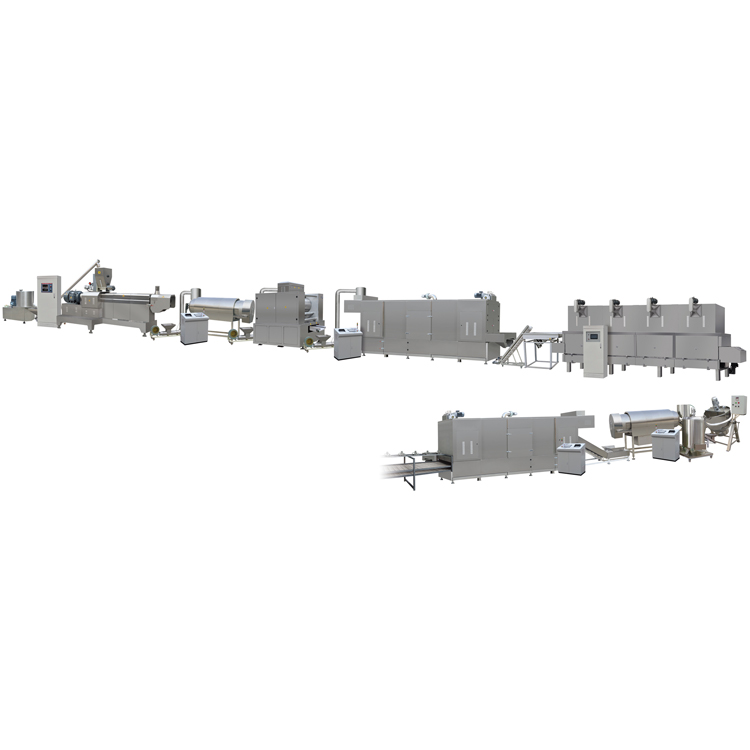

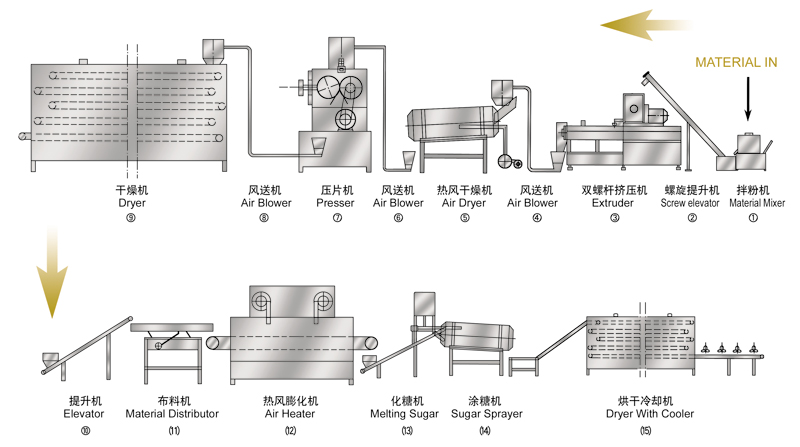

Automatic Breakfast Cereal Corn Flakes Processing Line Flow Chart:

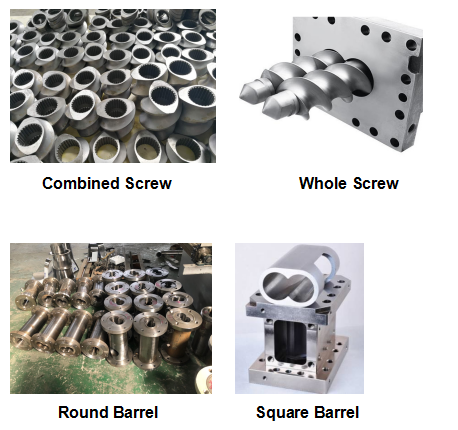

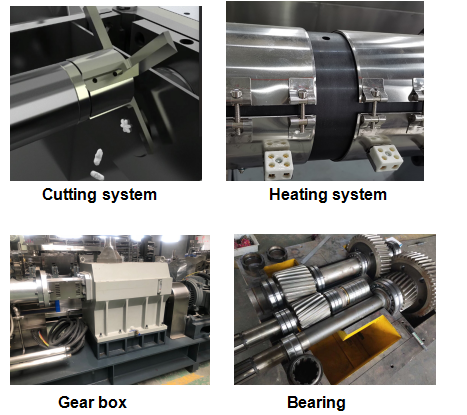

Main Machine Details:

Vacuum transporter |  | Feeding speed is fast and the continuous working time is long. The pipeline is completely enclosed and there is no leakage. Clean and suitable for clean workshops. |

Breakfast Cereal Corn Flakes Extruder |

| 1.Cereal Corn Flakes Extruder adopts the design of combined functional screws. The production parameters can be controlled automatically and accurately. 2. Feeding, main driving device, and rotary cutting device adopt inverter to adjust the speed with more powerful drive, stable running, and low consumption. 3. Screw is made of alloy steel with long life. 5.special design of gearbox by has long service life |

Air Roller Dryer |

| Air roller dryer is to dry water contained in the material. Material extruded from the extruder is high water percentage and high density. After getting into the roller material explore in the hot air, as the roller rolling the water in the material will be dried. |

Tablet machine /Flaker/ Presser |

| Tablet machine /Flaker/ Presser avoid corn flakes go through the presser become overlapped; a quantity control part is designed with it. The twin rollers are made of high rigidity metal in order to use in a long term, also it has automatic cooling system with it. Scraper is well designed and easy to operate. High standard rollers and scraper is the guarantee of quality corn flakes. Tablet machine /Flaker/ Presser has friendly interface and easy operating procedures. |

Hot Air Heater | | Hot air heater using the advanced technology in this field of high temperature air heating method, this method can puff the material in a short time in order to make them more puffed. The reason for using high temperature air is that materials can be heated evenly and quickly. We designed automatic leftover collecting device with the equipment, it also has characteristics like friendly interface and easy to operate. The Air Heater was build up by 4 sets( 6 sets) of heating porters, stainless conveyor belt, automatic leftover collecting device, hot air pipes and warm keeping pipes. Equipment applied hot air convection and circulating flow principle, it is an unique puffing machinery technique national wide.

|

Sugar Sprayer |

| The sugar sprayer was buildup by the roller and spraying system, the roller was drive by a motor, corn flakes will enter the roller from one end, so they can rolling with the roller and the sugar will sprayed on the corn flakes evenly. The volume of liquid sugar is adjustable. Sugar coating roller with insulation system

|

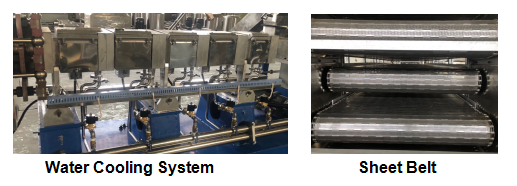

Baking machine with Cooler |

| After the sugar sprayed, the corn flakes will enter this baking machine automatically, to vaporize the water inside the sugar. The baking machine was design in five layers; it was buildup by motor, stainless conveyor belt, infrared ray heater. This design has many advantages such as multipurpose usage and heating system balance etc. The baking machine is used for vaporize the water inside the corn flakes, working progress non-stopping, drying time adjustable. At the end of the baking machine, there is a cooling belt, it will cooling the corn flakes fast, and makes the sugar agglomeration. |

Automatic Packing Machine |

| Combination head weigher Vertical automatic packing machine . we have model 420, 520, 620 and 720 vertical packing machine. Which is chosen according to the weight of your packing bags and shape. Together with packing machine, air compressor, nitrogen system is also optional according to your basic requirements. |

Technical Parameter:

Model parameter | DS65 Automatic Breakfast Cereal Corn Flakes Processing Line | DS75 Automatic Breakfast Cereal Corn Flakes Processing Line | DS85 Automatic Breakfast Cereal Corn Flakes Processing Line |

Installed power | 180kw | 200kw | 240kw |

Power consumption | 126kw | 140kw | 168kw |

output | 120-150kg/h | 200-300kg/h | 300-500kg/h |

Length | 48m | 58m | 68m |

Main Accessories:

Company Information:

Our Advantages:

1. High qulity: Using high quality material and establishing a strict quality control system, assigning

specific persons in charge of each part of production, from raw material purchase to assembly.

2. Professional R&D center. Employed designers with 10 years working experience in food indus-

try. Each month will release a new senies of products. OEM and ODM are warmly welcomed.

3. In General, the delivery date will be 20 working days for normal buy quantity. But if bigger order,

please check us further.

Factory:

Package & Shipping:

Outer Packing---Wooden case

Inner Packing----Wrapped with plastic film

FAQ

Q1. Are you a manufacturer or a trading company?

A1: We are a professional manufacturer of food & feed extrusion machine.

Q2. What after-services do you provide?

A2: Send engineers for installation, trial running and training workers at customer's site.

Handling the problems occurred during use. Supply spare and wearing parts on discount.

Help customers to solve any other proble

Q3. If machines wearing parts need changing, what should we do?

A3.We can offer the wearing parts all the time, and offer video.

Q4. What's the payment terms if we want to buy the machines?

A4.L/C, TT 30% down payment, 70% balance before delivery.

Q5. Can you provide food or feed formula?

A:We can provide basic formula for produce the food etc.

And help customer to produce new products according to customer’s formula.

Our Services:

Pre-sale service

1 Related machines' technical parameter will be supplied to customer.

2. According to customer's factory size, factory layout can be provided in advance.

3. According to customer's material cost, general formulation can be prepared well.

4. Special machine can be supplied as customer's request.

5. Professional Advice about Market, machines, processing, materials, packing can be supplied.

6. Suggesting professional ship agent or helping book ship as customer request.

Installation and after-sale service system

1. Allocation chart as the buyer's request will be supplied.

2. Operation manual will be supplied after shipment.

3. One year warrantee, life time maintenance with cost price.

4. Free easy broken spare parts will be sent with container .

5. First installation can be done by engineer.

6. Training workers in customer's factory.

Exhibition review: