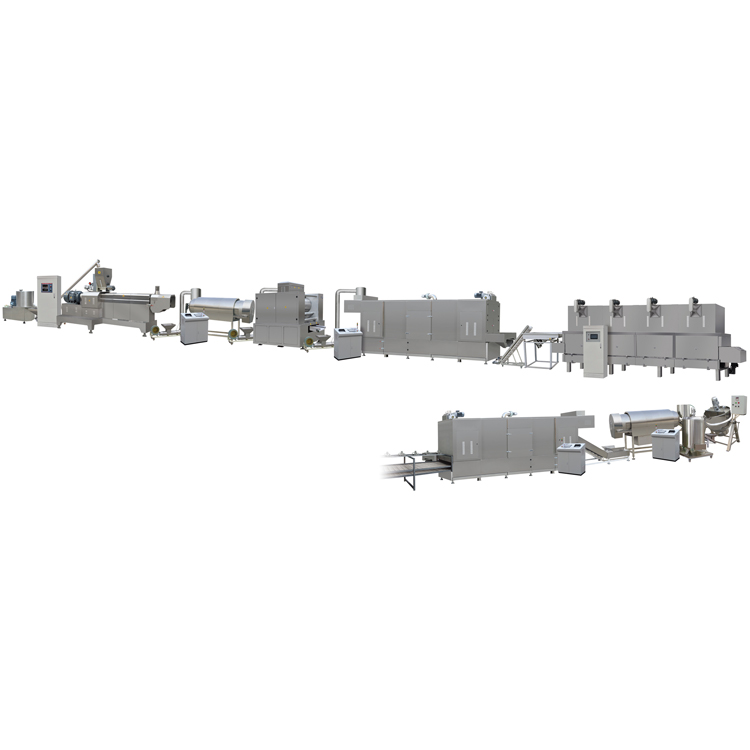

Breakfast Cereal Corn Flakes Production Line

- HXSD

- China

- 30 Days After Order

- 15 Set/month

Breakfast Cereal Corn Flakes Production Line main motor brand is SIEMENS. Breakfast Cereal Corn Flakes Production Line Relay: ABB or customized. Breakfast Cereal Corn Flakes Production Line Inverter is Delta. Breakfast Cereal Corn Flakes Production Line material generally is Food grade stainless steel. All the electric device brand can be customized as you need. Baking Machine source can be designed use Electricity, Gas, Oil or stream.

Product Description:

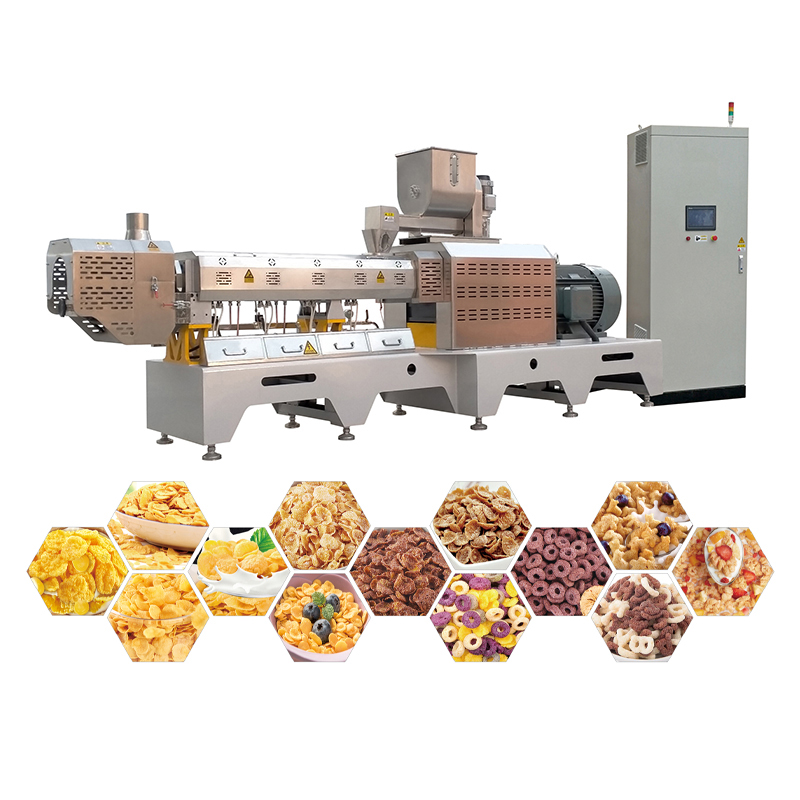

Breakfast Cereal Corn Flakes Production Line is applied to make corn flakes, cereal snacks such as coco ball ,crispy rice ,fruit loops and so on , the famous brands are Kelloggs and Nestle in the world .

The main machine for Breakfast Cereal Corn Flakes Production Line is extruder , which can adopt corn flour ,rice flour ,wheat flour ,oat flour and so on as main raw material.

Breakfast Cereal Corn Flakes Sample Show:

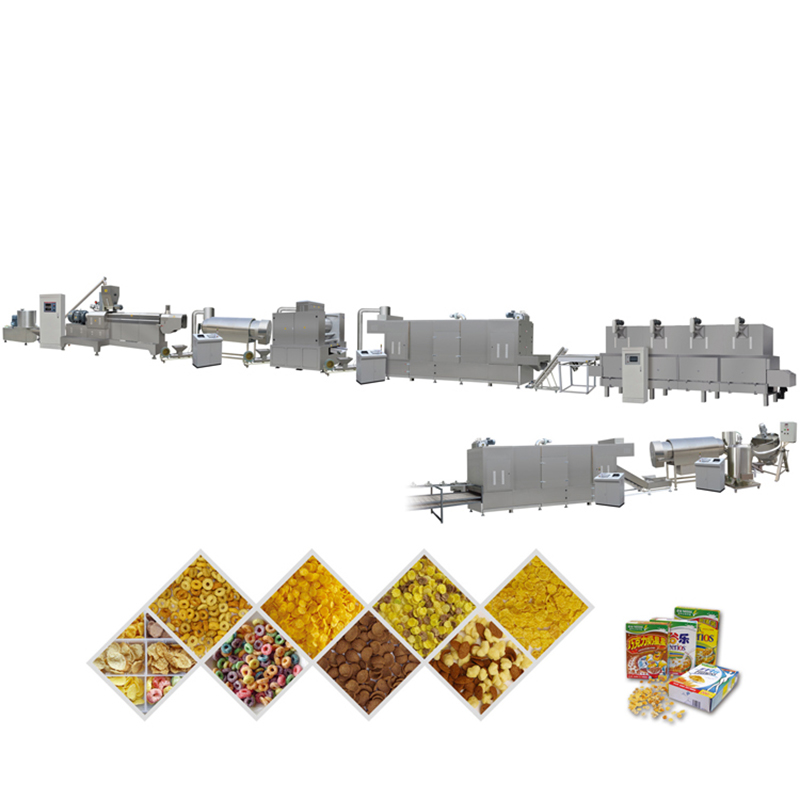

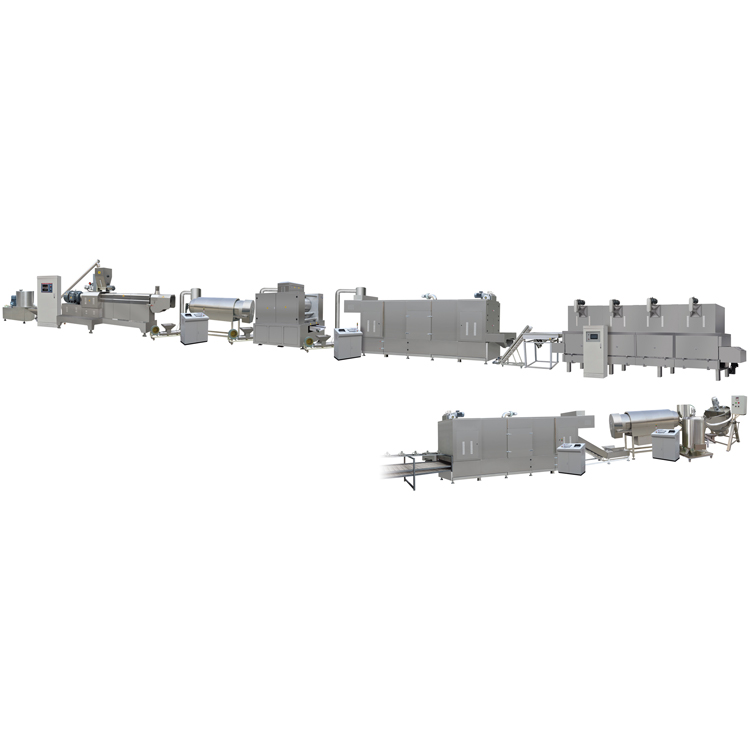

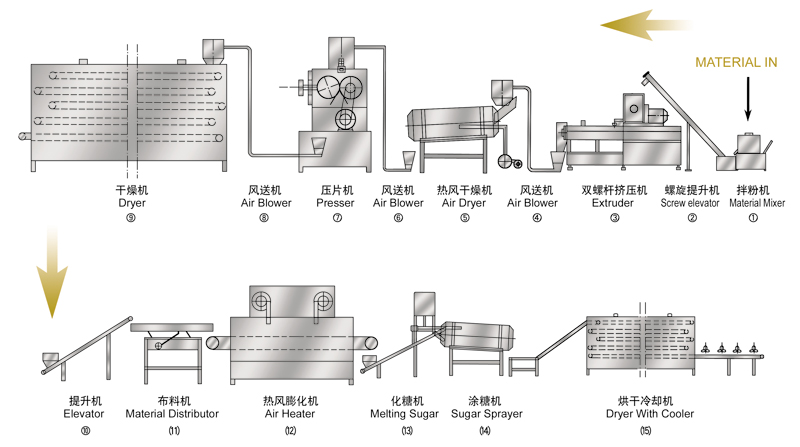

Breakfast Cereal Corn Flakes Production Line Flow Chart:

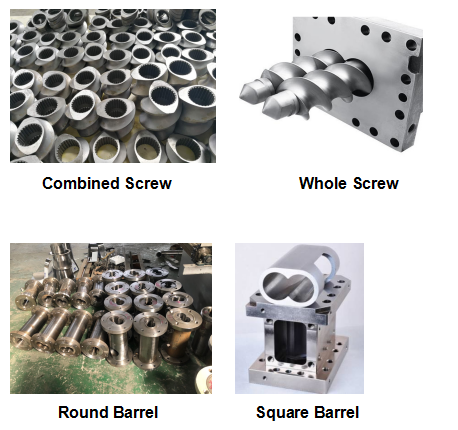

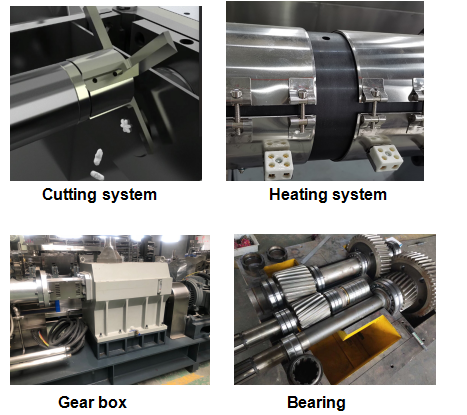

Breakfast Cereal Corn Flakes Production Line Main Details:

Breakfast Cereal Corn Flakes Extruder |

| 1. Swiss Technology,made in China; 2. PLC touch screen for Centralized ,accurate,convenient control 3. Fully automatic control system for heating and circulated cooling accurately 4. Direct transmission of motor and distribution box reduces energy loss. 5. Imported bearing group with higher bearing capacity 6. Breakfast Cereal Corn Flakes Extruder with water injecting device on barrel to meet require of various raw material and quality. 7. High-speed tool steel with hardness HRC≥62 to ensure a longer service life. 8. Modular combination of screws at will to meet require of different raw material. 9. Suspension type rotary cutter with bearing adjusting device to ensure quick,safe and accurate 10. All barrels inlaid alloy sleeve, easy to replace and extend the life span of screw. All barrels inlaid cooling water through, spread around alloy sleeve, and can accurate constant temperature required 11. All screw sleeves is kneading, ensure that not accumulate material. The screw is installed by blocks, and can be replaced optionally ratio to achieve requirements for product. Screw sleeve is installed by spline, and it is convenient and efficient. Quality of screw sleeve according to different prices is divided into: Cr12MoV, 38CrMoAl38, W6Mo5Cr4V2. 12. Applied to make all kinds of extrusion products such as corn flakes , cereal snacks ,puff snacks ,wheaten snacks , 2d /3d snack pellets , pet food ,fish feed ,soya protein ,nutritiobal powder ,modified starch and so on. |

Air Blower |

| blow the pellet balls to the next machine

|

Air Roller Dryer |

| Main function of this equipment Is to dry water contained in the material. Material extruded from the extruder is high water percentage and high density. |

Tablet machine /Flaker/ Presser |

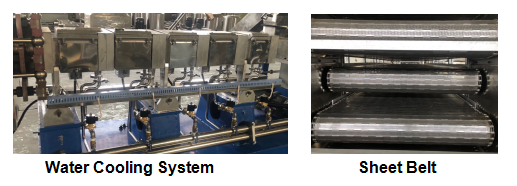

| As a key machine of the Breakfast Cereal Corn Flakes Production Line, this machine has high automaticity, can adjust the gap between compression rollers to ensure the thickness of products. Two compression rollers can adjust the gap between 0.3-3mm, and guarantee press uniformly, the inner of two compression roller are all have the constant temperature recirculating water, to ensure the temperature of compression rollers in order to avoid the stickness of materials. |

Dryer |

| dry the corn flakes to take away most of the moisture content

|

Hot Air Heater | | Hot air heater use the advanced technology in this field of high temperature air heating method, this method can puff the material in a short time in order to make them more puffed. The reason for using high temperature air is that materials can be heated evenly and quickly. We designed automatic leftover collecting device with the equipment, it also has characteristics like friendly interface and easy to operate.

|

Melting Sugar Machine |

|

|

Sugar Sprayer |

| The sugar sprayer was buildup by the roller and spraying system, the roller was drive by a motor, corn flakes will enter the roller from one end, so they can rolling with the roller and the sugar will sprayed on the corn flakes evenly. The volume of liquid sugar is adjustable.

|

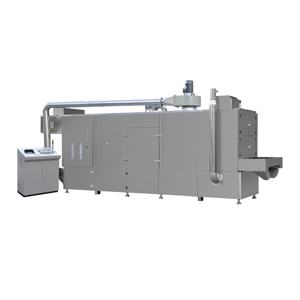

Oven with Cooler |

| After the sugar sprayed, the corn flakes will enter the oven automatically, to vaporize the water inside the sugar. This design has many advantages such as multipurpose usage and heating system balance etc. This oven is used for vaporize the water inside the corn flakes, working progress non-stopping, drying time adjustable. At the end of the oven, there is a cooling belt, it will cooling the corn flakes fast, and makes the sugar agglomeration. |

Automatic Packing Machine |

| Combination head weigher Vertical automatic packing machine . Which is chosen according to the weight of your packing bags and shape. |

Technical Parameter:

Model parameter | DS65 Breakfast Cereal Corn Flakes Production Line | DS75 Breakfast Cereal Corn Flakes Production Line | DS85 Breakfast Cereal Corn Flakes Production Line |

Installed power | 180kw | 200kw | 240kw |

Power consumption | 126kw | 140kw | 168kw |

output | 120-150kg/h | 200-300kg/h | 300-500kg/h |

Length | 48m | 58m | 68m |

Main Accessories:

Company Information:

Our Advantages:

1. High qulity: Using high quality material and establishing a strict quality control system, assigning

specific persons in charge of each part of production, from raw material purchase to assembly.

2. Professional R&D center. Employed designers with 10 years working experience in food indus-

try. Each month will release a new senies of products. OEM and ODM are warmly welcomed.

3. In General, the delivery date will be 20 working days for normal buy quantity. But if bigger order,

please check us further.

4. Small order accepted: Low MOQ accepted 2pcs are available.

Factory:

Package & Shipping:

Inside package is plastic film, outside is wooden or plywood case

(based on the customers' need).

1. Only plastic film nude packing with wooden pallet.

2. We can supply fumigation package and certificate.

3. Shipping, train, express or upon clients' demands.

FAQ

Q1. What's the pre-sale service of your company?

A1 Related machines' technical parameter will be supplied to customer.

1.1 According to customer's factory size, factory layout can be provided in advance.

1.2 According to customer's material cost, general formulation can be prepared well.

1.3Special machine can be supplied as customer's request.

1.4 Professional Advice about Market, machines, processing, materials, packing can be supplied.

1.5 Suggesting professional ship agent or helping book ship as customer request.

Q2. What's the after-sale service of your company?

A2.1Allocation chart as the buyer's request will be supplied.

2.2 Operation manual will be supplied after shipment.

2.3One year warrantee, life time maintenance with cost price.

2.4 Free easy broken spare parts will be sent with container .

2.5 First installation can be done by engineer.

2.6Training workers in customer's factory.

Q3. If machines wearing parts need changing, what should we do?

A3.We can offer the wearing parts all the time, and offer video.

Q4. What's the payment terms if we want to buy the machines?

A4.L/C, TT 30% down payment, 70% balance before delivery.

Q5: How about the delivery date?

A5: In General, the delivery date will be 20 working days for normal buy quantity. But if bigger order, please check us further.

Q6: How about the label and the logo?

A6: Customize label and logo is workable.

Customers:

As a professional Breakfast Cereal Corn Flakes Production Line manufacturer, we have exported the Breakfast Cereal Corn Flakes Production Line to more than 80 countries and regions, such as South Africa, India, Malaysia, Indonesia, Brazil and so on. Some of customers become our agents in their area. We hope to have long friendly business relationship with more Breakfast Cereal Corn Flakes Production Line customers from all over the world in the future.

Our Services:

I. We has professional team to design the whole production line according to your requirements

II. we also help our client to develop the old production line and carry out new products

III. Custiomized factory layout designed is provided by our professionals

IV. Overseas technicians are available to help the clients for installation and adjustment

V. 12 months warranty for the machines , 24 months for some parts

Exhibition review: