Children’s Educational Toys Production Line

- HXSD

- China

- 30 Days After Order

- 15 Set/month

Children’s Educational Toys Production Line is kind of new application of extrusion technology. Children’s Educational Toys Production Line uses vegetable starch as main raw material. Starch-based foam pellet can be widely used, such as “educational sticky toys” “Magic corn kernels” “DIY corn kernels” etc. After lightly wet, it can be bonded with each other, and cut, press to create infinite styles.What’s more, it also can be used on packaging and filling material which can fill in the items packaging space quickly and evenly. Starch-based foam pellet is applied widely since it is green, safe for children and environment, 100% biodegradable, nontoxic, light-weight, anti-static etc.

Product Description:

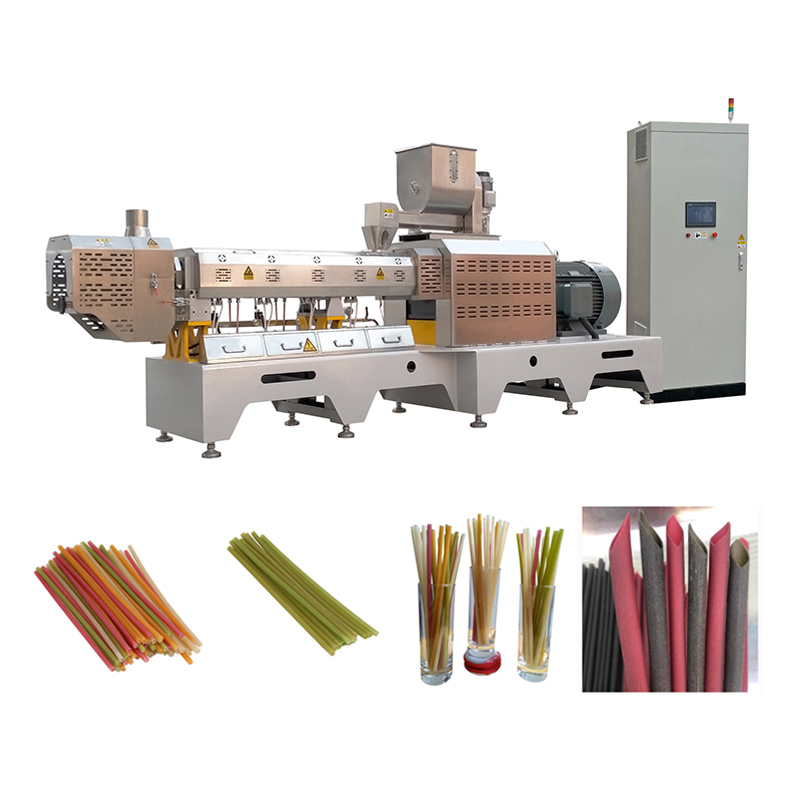

Children’s Educational Toys Production Line Sample Show:

Children’s Educational Toys Production Line Technical Parameter:

Model | Output | power |

DS65 Children’s Educational Toys Production Line | 100-200kg/h | 80kw |

DS70 Children’s Educational Toys Production Line | 100-250kg/h | 90kw |

DS75 Children’s Educational Toys Production Line | 200-350kg/h | 105kw |

DS85 Children’s Educational Toys Production Line | 300-500kg/h | 120kw |

DS100 Children’s Educational Toys Production Line | 700-1000kg/h | 150kw |

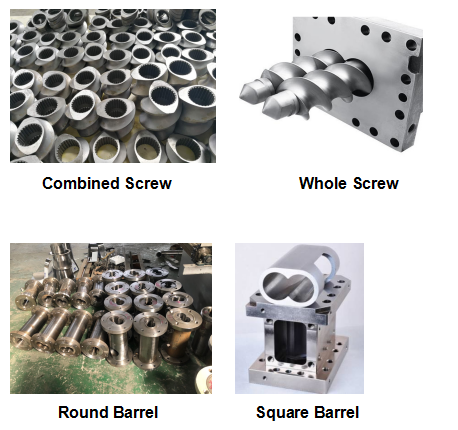

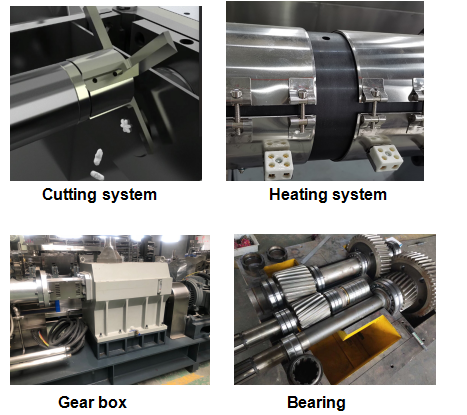

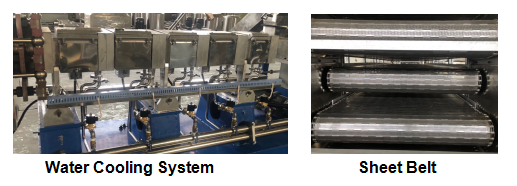

Children’s Educational Toys Production Line Main Details:

Double SCREW Extruder | | 1. PLC touch screen for Centralized ,accurate, convenient control 2. Fully automatic control system for heating and circulated cooling accurately 3. Direct transmission of motor and distribution box reduces energy loss. 4. Imported bearing group with higher bearing capacity 5. Equipment with water injecting device on barrel to meet require of various raw material and quality. 6. High-speed tool steel with hardness HRC≥62 to ensure a longer service life. 7. Suspension type rotary cutter with bearing adjusting device to ensure quick, safe and accurate 8. All barrels inlaid alloy sleeve, easy to replace and extend the life span of screw. All barrels inlaid cooling water through, spread around alloy sleeve, and can accurate constant temperature required 9. All screw sleeves is kneading, ensure that not accumulate material. The screw is installed by blocks, and can be replaced optionally ratio to achieve requirements for product. Screw sleeve is installed by spline, and it is convenient and efficient. Quality of screw sleeve according to different prices is divided into: Cr12MoV, 38CrMoAl38, W6Mo5Cr4V2. |

Main Accessories:

Company Information:

Our Advantages:

1. High qulity: Using high quality material and establishing a strict quality control system, assigning

specific persons in charge of each part of production, from raw material purchase to assembly.

2. Professional R&D center. Employed designers with 10 years working experience in food indus-

try. Each month will release a new senies of products. OEM and ODM are warmly welcomed.

3. In General, the delivery date will be 20 working days for normal buy quantity. But if bigger order,

please check us further.

4. Small order accepted: Low MOQ accepted 2pcs are available.

Factory:

Package & Shipping:

Inside package is plastic film, outside is wooden or plywood case

(based on the customers' need).

1. Only plastic film nude packing with wooden pallet.

2. We can supply fumigation package and certificate.

3. Shipping, train, express or upon clients' demands.

Customers:

Our Services:

I. We has professional team to design the whole production line according to your requirements

II. we also help our client to develop the old production line and carry out new products

III. Custiomized factory layout designed is provided by our professionals

IV. Overseas technicians are available to help the clients for installation and adjustment

V. 12 months warranty for the machines , 24 months for some parts

Exhibition review: