Degradable Straw Extruder Production Line

Degradable Straw Extruder Production Line is a new application of extrusion technology. The main raw material of the Degradable Straw Extruder Production Line is starch, which is extruded, gelatinized and foamed by twin-screw extruder, so that it can be processed into a new type of fully degradable and edible product without adding any foaming agent. Degradable tableware is widely used because of its environmental protection, non-toxic, harmless, light weight, anti-static and other characteristics

Degradable Straw Extruder Production Line feature:

1. Degradable Straw Extruder Production Line main motor brand is SIEMENS.

2. Relay: ABB or customized.

3. Degradable Straw Extruder Production Line Inverter brand is Delta.

4. All the electric device brand can be customized as you need.

5. Baking machine source can be designed use Electricity, Gas, Oil or stream.

6. Degradable Straw Extruder Production Line material generally is Food grade stainless steel, also can customized as require.

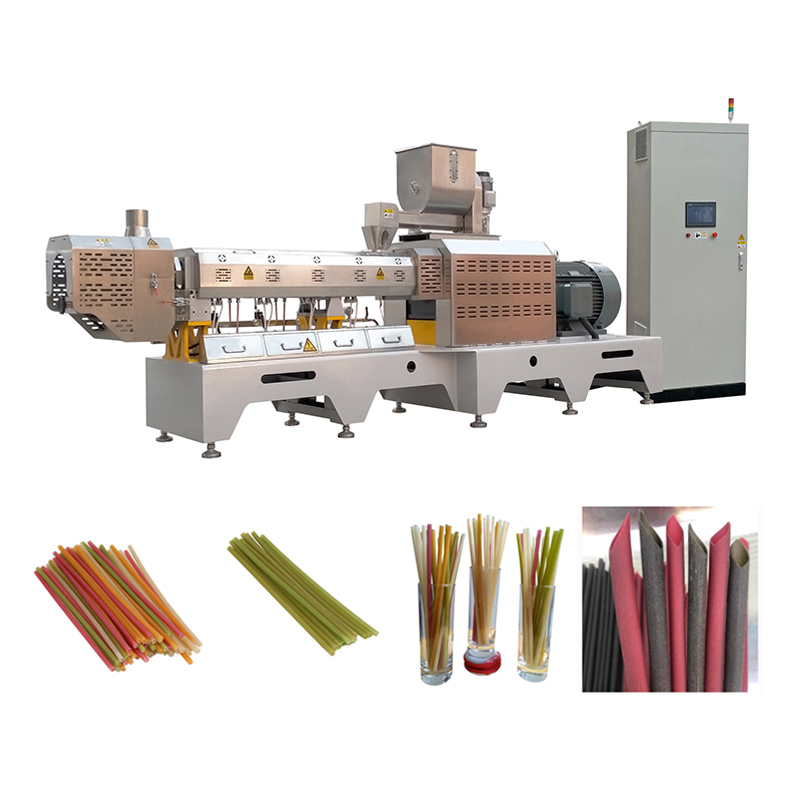

Edible Straw Machine Drinking Rice Straw Extrusion Machine Sample Show:

Degradable Straw Extruder Production Line Technical Parameter:

Model | Output | power |

DS65 Degradable Straw Extruder Production Line | 100-200kg/h | 80kw |

DS70 Degradable Straw Extruder Production Line | 100-250kg/h | 90kw |

DS75 Degradable Straw Extruder Production Line | 200-350kg/h | 105kw |

DS85 Degradable Straw Extruder Production Line | 300-500kg/h | 120kw |

DS100 Degradable Straw Extruder Production Line | 700-1000kg/h | 150kw |

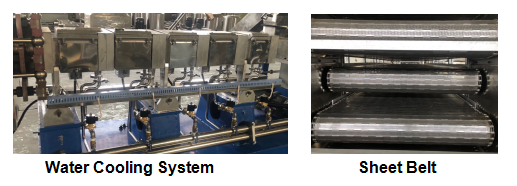

Degradable Straw Extruder Production Line Main Details:

Mixer | | Mix the raw material equally |

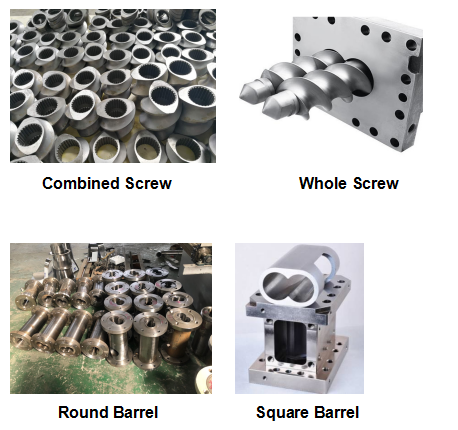

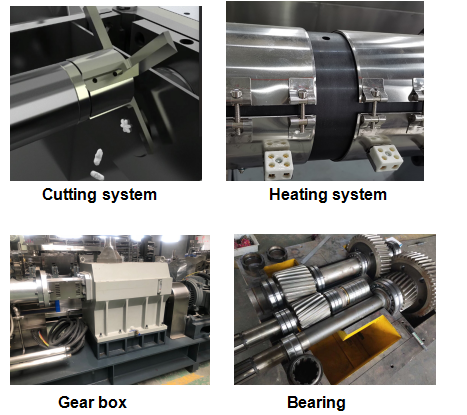

Double SCREW Extruder | | 1. Extruder adopts the design of combined functional screws. The production parameters can be controlled automatically and accurately. 2. Frequency converter to control feeding device, extrusion screw, rotating cut. 3. Wearable alloy steel screw lives a long life. 4 . Imported bearing group with higher bearing capacity 5. Automatic lubrication system ensure running stable and long life 6.Self-cleaning function and different slenderness ratios is another feature of twin screw extruder. |

Air Blower |

| The main function of air conveyor is to transmit material from upper level machine to next level machine. It contains air blower, feeding cone and air pipe etc, it is an equipment with multipurpose function. |

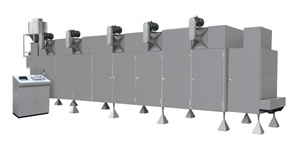

Dryer

| | 1.Heating source can be electric, gas, steam, fuel... 2. These series of roasting oven are widely used, it is used for drying all kinds of stick, piece, grain etc. puffed snacks, nutritional powder, bread crumb, pet food, textured vegetarian protein etc. 3. the user can choose different layer, length of dryer according to different product. 4. Drying temperature and time can be adjusted, effect of drying is capitally. |

Main Accessories:

Company Information:

Our Advantages:

1. High qulity: Using high quality material and establishing a strict quality control system, assigning

specific persons in charge of each part of production, from raw material purchase to assembly.

2. Professional R&D center. Employed designers with 10 years working experience in food indus-

try. Each month will release a new senies of products. OEM and ODM are warmly welcomed.

3. In General, the delivery date will be 20 working days for normal buy quantity. But if bigger order,

please check us further.

4. Small order accepted: Low MOQ accepted 2pcs are available.

Factory:

Package & Shipping:

Inside package is plastic film, outside is wooden or plywood case

(based on the customers' need).

1. Only plastic film nude packing with wooden pallet.

2. We can supply fumigation package and certificate.

3. Shipping, train, express or upon clients' demands.

Customers:

Our Services:

Before sale services:

1. Provide the free consultation of the equipment.

2. Provide the standard device and the flow chart.

3. According to the clients’ special requirement, offering the reasonable plan and free design helping to select the equipment.

Services during the sales:

1. Help client design the factory and offering professional advice, free engineering drawing for the factory layout.

2. Welcome to visit our factory or the domestic clients’factory.

3. Inspect the machine before leaving the factory.

After sale services:

1. Oversea install and debug the equipment.

2. Train the first-line operator.

3. Provide the basic formula

4. Operation/ Service/ Maintenance Manual: Provided In English.

5. We will provide 1-2 engineer to the client's factory for the installation and training. The client need provide room, food, round-trip transportation, visa fee and a nominal daily subsidy per person.

Exhibition review: