Corn Flakes Making Breakfast Cereal Machine

- HXSD

- China

- 30 Days After Order

- 15 Set/month

People are always looking for Corn Flakes Making Breakfast Cereal that are both nutritious and convenient. Experts are working with food processing professionals to develop new solutions to produce more ready-to-eat Corn Flakes Making Breakfast Cereal. Corn Flakes Making Breakfast Cereal Machine main motor brand is SIEMENS. Corn Flakes Making Breakfast Cereal Machine Inverter can be Delta. Corn Flakes Making Breakfast Cereal Machine material generally is Food grade stainless steel, also can customized as require.

Product Description:

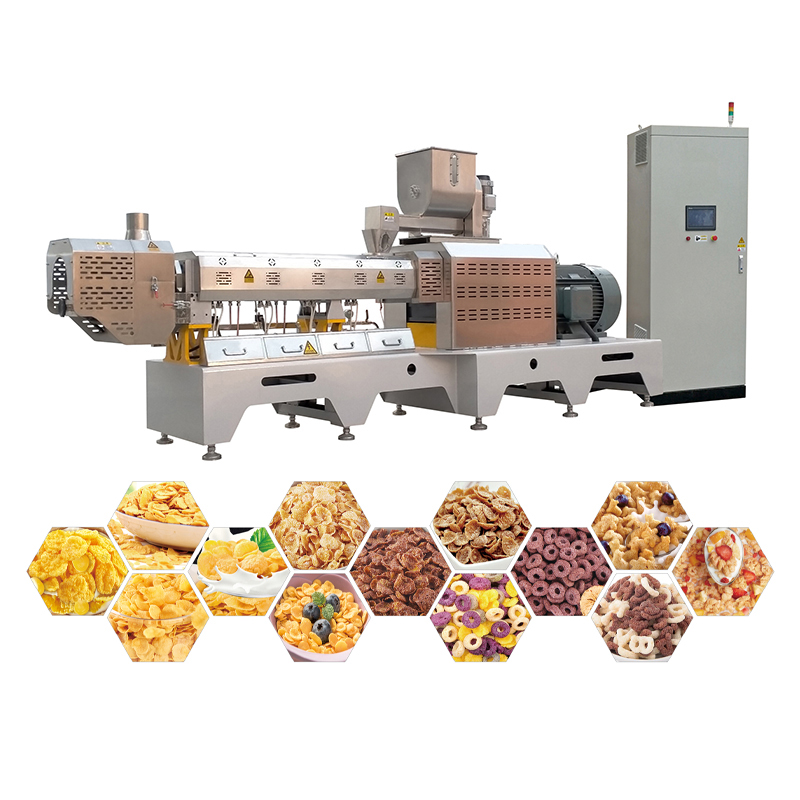

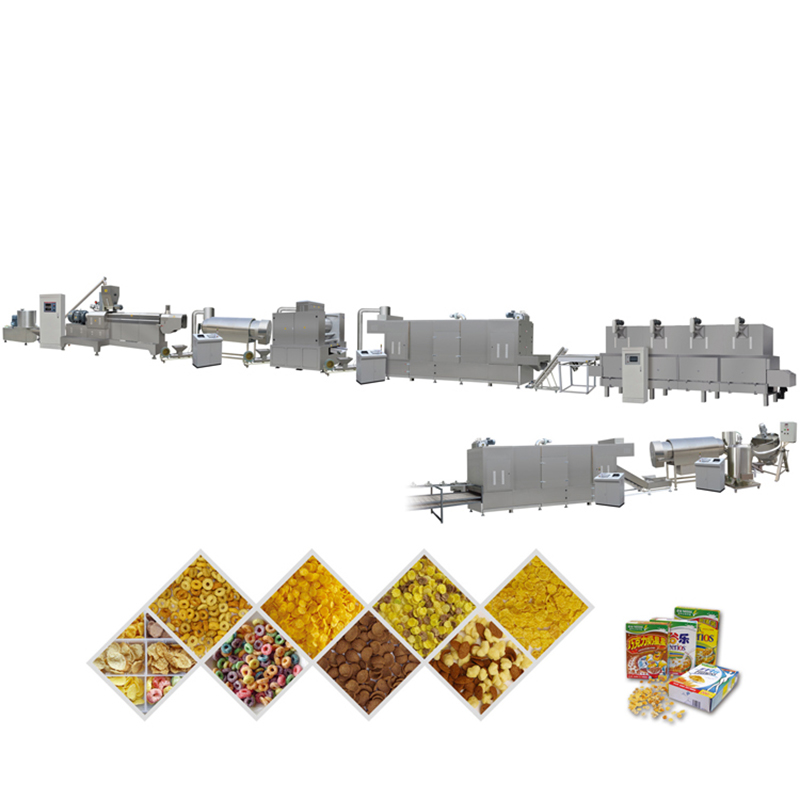

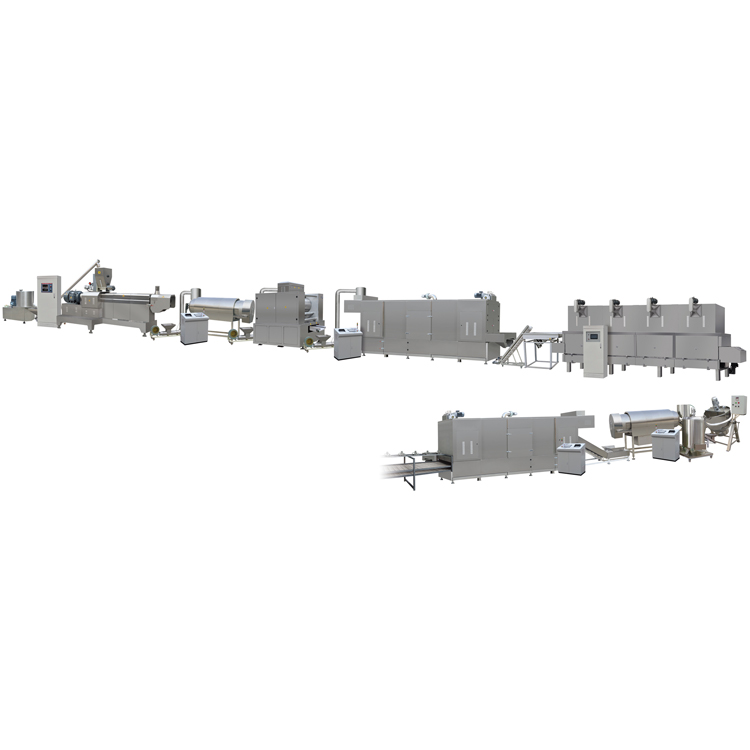

Breakfast Cereal Corn Flake Machine Corn Flakes Production Line is a fully automatic processing line which is designed and developed from our company combining with European advanced technology.

The production line uses corn flour, wheat flour, oat etc as its raw material. By twin screw extruder to accomplish cook curing, pelleting etc. Then by flakes pressing, baking, coating and other technological process to produce instant-eat crispy breakfast cereal corn flakes with regular, sweet, salty etc flavors.

Its breakthrough solves various difficult problem compared with domestic equipment, for example: pressing rollers sticking, low capacity of flakes pressing, low shaping rate, poor taste etc. Scientific processing technique can keep cereals nutritional elements.

Reasonable equipments collocation and realizable process control ensure to produce nutritional crispy breakfast cereal corn flakes with various shapes and sizes.

The processing line not only can reduce costs, but also can improves market competitiveness.

Raw material:

Corn, rice, wheat, oat, barley etc. as coating, cream, chocolate, fruit paste, date paste, jelly etc. as filling.

Sample Show:

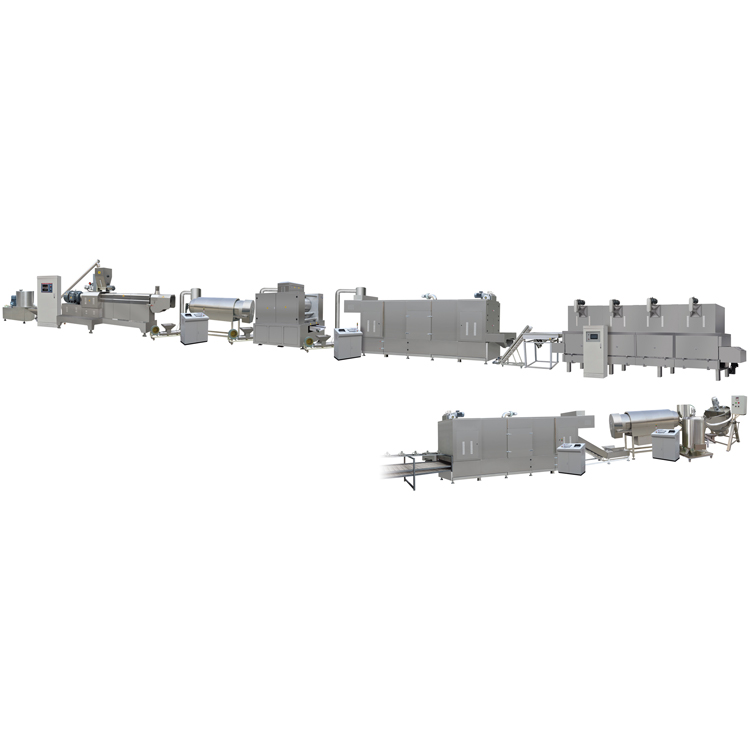

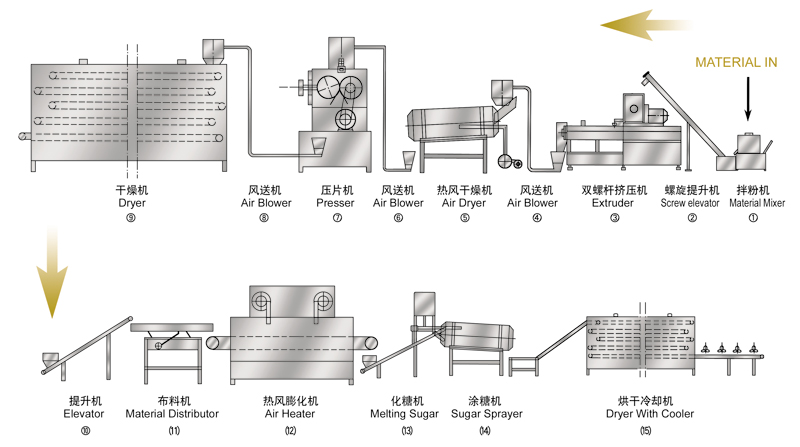

Flow Chart:

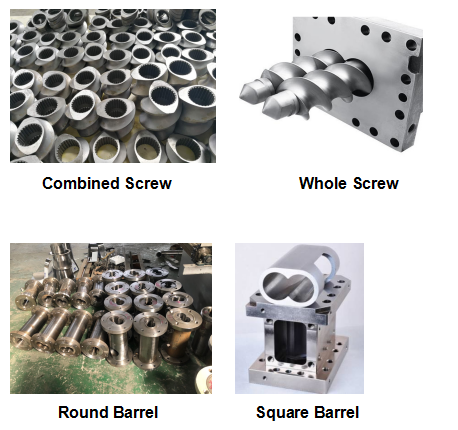

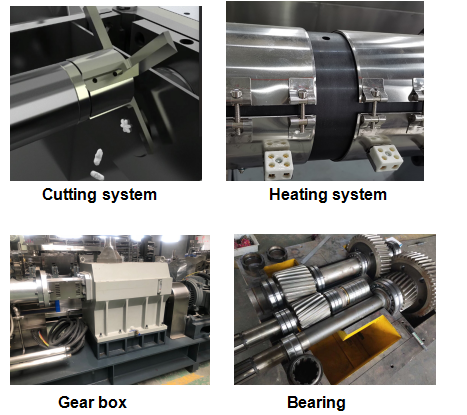

Main Machine Details:

Mixer |

| 1. Adopted the speed reducer motor connected directly with the mixing wings, then bring the mixing blade high efficiency take rounds to mix the flour flakes material inside of mixer. 2. The transmission efficiency of 100%, increase the torque. Then higher the mixing quantity up to 50-60kg per batch with stronger power. |

Screw Conveyor |

| It uses helix screw, transporting mixed raw materials into the extruder. The entire elevator is all made by stainless steel, easy to operate. Shift time can be adjusted, also it is fully automated. Capacity: Max 1000kg/h Dimension: 1600*300*20mm

|

Double Screw Extruder |

| 1.Extruder adopts the design of combined functional screws. The production parameters can be controlled automatically and accurately. 2. Feeding, main driving device, and rotary cutting device adopt inverter to adjust the speed with more powerful drive, stable running, and low consumption. 3. Screw is made of alloy steel with long life. 5.special design of our gearbox by our company .long service life |

Air Blower |

| The main function of air conveyor is to transmit material from upper level machine to next level machine. It contains air blower, feeding cone and air pipe etc, it is an equipment with multipurpose function, it can work under many snack food production line. Motor:2840RPM

|

Air Roller Dryer |

| Main function of this equipment Is to dry water contained in the material (screw leading way in the roller). Material extruded from the extruder is high water percentage and high density. After getting into the roller material explore in the hot air, as the roller rolling the water in the material will be dried. |

Tablet machine /Flaker/ Presser |

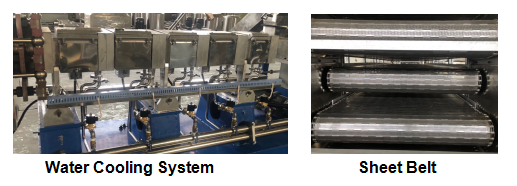

| This is the key equipment in corn flakes production line. Avoiding corn flakes go through the presser become overlapped; a quantity control part is designed with it. The twin rollers are made of high rigidity metal in order to use in a long term, also it has automatic cooling system with it. Scraper is well designed and easy to operate. High standard rollers and scraper is the guarantee of quality corn flakes. This equipment has friendly interface and easy operating procedures. |

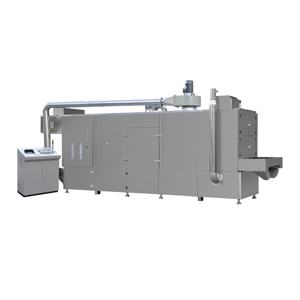

Dryer |

| The three layers drier is reciprocating structure, it contains transmission electrical motor, stainless steel carrying belt, infrared heating pipes and supporting frame. As snacks go through the drier, they will be dried quickly in a clean condition. In the corn flakes production line, this drier can dry materials quickly after presser step.

|

Hoister / Elevator |

| Elevating material already dried to the next machine material distributor.

|

Vibrator / Material Distributor |

| Through shaking method spread materials evenly to hot air heater. |

Hot Air Heater | | Hot air heater: this equipment using the advanced technology in this field of high temperature air heating method, this method can puff the material in a short time in order to make them more puffed. The reason for using high temperature air is that materials can be heated evenly and quickly. We designed automatic leftover collecting device with the equipment, it also has characteristics like friendly interface and easy to operate. The Air Heater was build up by 4 sets( 6 sets) of heating porters, stainless conveyor belt, automatic leftover collecting device, hot air pipes and warm keeping pipes. Equipment applied hot air convection and circulating flow principle, it is an unique puffing machinery technique national wide.

|

Melting Sugar Machine |

| Resistant baffle in the temperature preservation jar will impact with the liquid which can mix evenly. The Melting Sugar Jar is the assistant equipments for the line. It was buildup by warming Jar and the mixing motor, used for mixing and melting the water, sugar and other additives.

|

Sugar Sprayer |

| The sugar sprayer was buildup by the roller and spraying system, the roller was drive by a motor, corn flakes will enter the roller from one end, so they can rolling with the roller and the sugar will sprayed on the corn flakes evenly. The volume of liquid sugar is adjustable. Sugar coating roller with insulation system

|

Dryer with Cooler |

| After the sugar sprayed, the corn flakes will enter the drier automatically, to vaporize the water inside the sugar. The drier was design in five layers; it was buildup by motor, stainless conveyor belt, infrared ray heater. This design has many advantages such as multipurpose usage and heating system balance etc. This equipment is used for vaporize the water inside the corn flakes, working progress non-stopping, drying time adjustable. At the end of the drier, there is a cooling belt, it will cooling the corn flakes fast, and makes the sugar agglomeration. |

Automatic Packing Machine |

| Combination head weigher Vertical automatic packing machine . we have model 420, 520, 620 and 720 vertical packing machine. Which is chosen according to the weight of your packing bags and shape. Together with packing machine, air compressor, nitrogen system is also optional according to your basic requirements. |

Technical Parameter:

Model parameter | DS65 Corn flakes production line | DS75 Corn flakes production line | DS85 Corn flakes production line |

Installed power | 180kw | 200kw | 240kw |

Power consumption | 126kw | 140kw | 168kw |

output | 120-150kg/h | 200-300kg/h | 300-500kg/h |

Length | 48m | 58m | 68m |

Main Accessories:

Company Information:

Factory:

Exhibition Review:

FAQ

Q1. What's the pre-sale service of your company?

A1 Related machines' technical parameter will be supplied to customer.

1.1 According to customer's factory size, factory layout can be provided in advance.

1.2 According to customer's material cost, general formulation can be prepared well.

1.3 Special machine can be supplied as customer's request.

1.4 Professional Advice about Market, machines, processing, materials, packing can be supplied.

1.5 Suggesting professional ship agent or helping book ship as customer request.

Q2. What's the after-sale service of your company?

A2.1 Allocation chart as the buyer's request will be supplied.

2.2 Operation manual will be supplied after shipment.

2.3 One year warrantee, life time maintenance with cost price.

2.4 Free easy broken spare parts will be sent with container .

2.5 First installation can be done by engineer.

2.6 Training workers in customer's factory.

Q3. If machines wearing parts need changing, what should we do?

A3. We can offer the wearing parts all the time, and offer video.

Q4. What's the payment terms if we want to buy the machines?

A4. L/C, TT 30% down payment, 70% balance before delivery.

Q5: How about the delivery date?

A5: In General, the delivery date will be 20 working days for normal buy quantity. But if bigger order, please check us further.

Q6: How about the label and the logo?

A6: Customize label and logo is workable.