Corn Flakes Making Processing Puffed Extruder

- HXSD

- China

- 30 Days After Order

- 15 Set/month

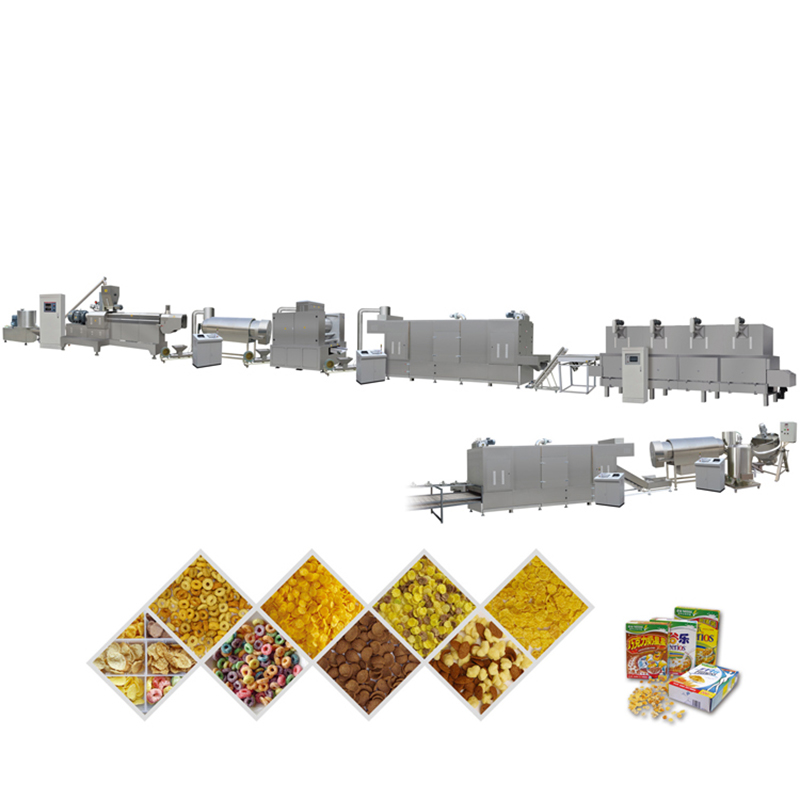

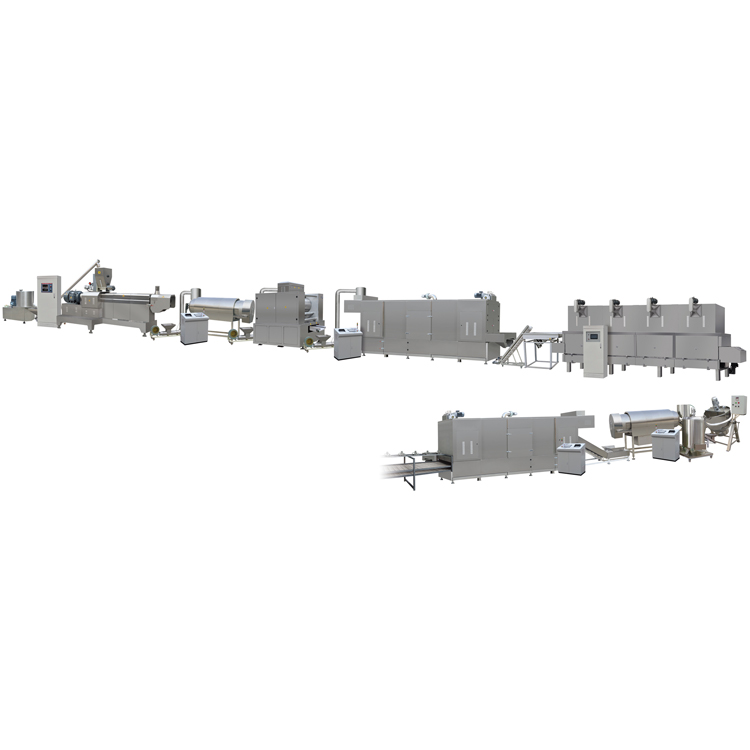

Corn Flakes Making Processing Puffed Extruder is developed and manufactured on the basis of the international advanced extruder technology, which is named corn flakes breakfast processing line. Its technology performance and quality can reach international advanced level. This line consists of mixing, boiling, pressing, drying and inflating, which can be finished one time, the level of this automation is very high.

Product Description:

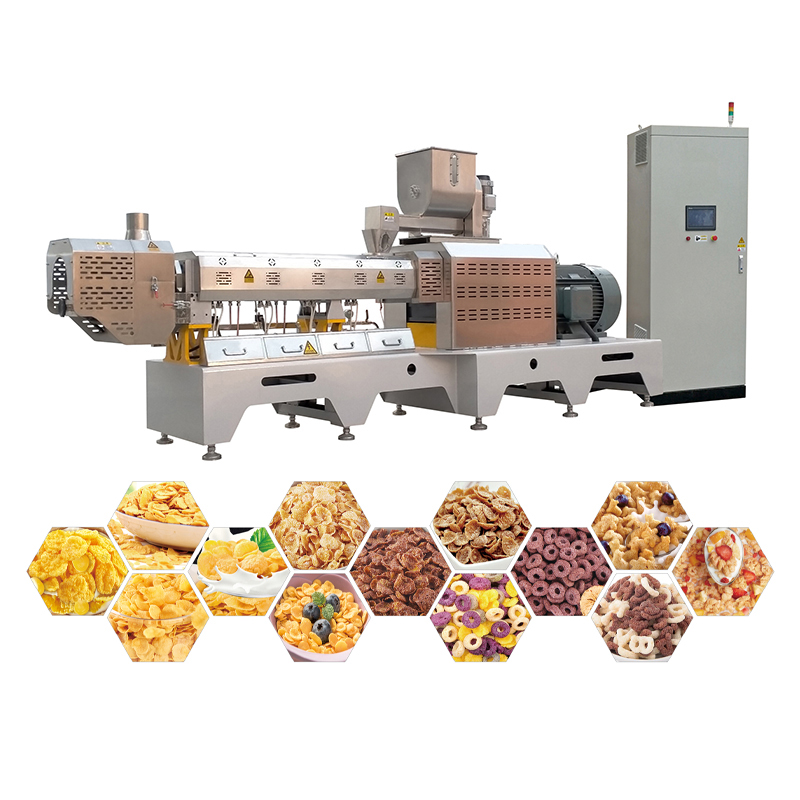

Corn Flakes Making Processing Puffed Extruder can be directly extruded from the extruder, dryer and flavoring machine. We can produce all kinds of snacks and different shapes by adjusting the dies from extruder. Snacks food line can take corn, rice, wheat, oat, rye and other grains as materials to produce extruded snacks, with crispy taste and lively shape, Snacks food processing line is designed according to market demand. It includes cheese balls, corn curls, corn sticks, coco pops, cereal, kurkure and pellets.

Reasonable equipments collocation and realizable process control ensure to produce nutritional crispy breakfast cereal corn flakes with various shapes and sizes.

Corn Flakes Making Processing Puffed Extruder not only can reduce costs, but also can improves market competitiveness.

Corn Flakes Making Processing Puffed Extruder Sample Show:

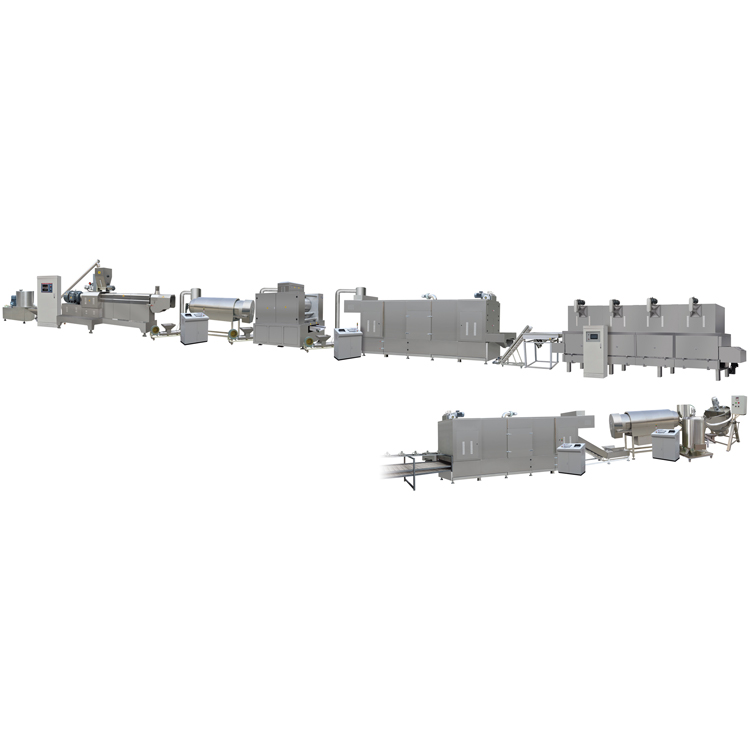

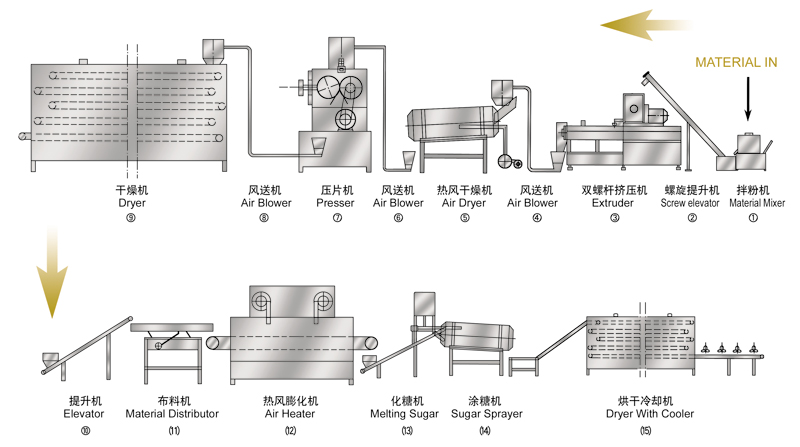

Corn Flakes Making Processing Puffed Extruder Flow Chart:

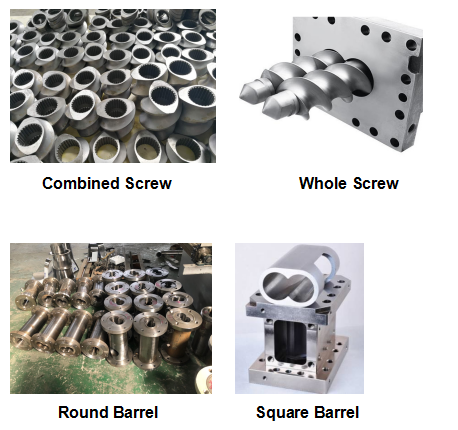

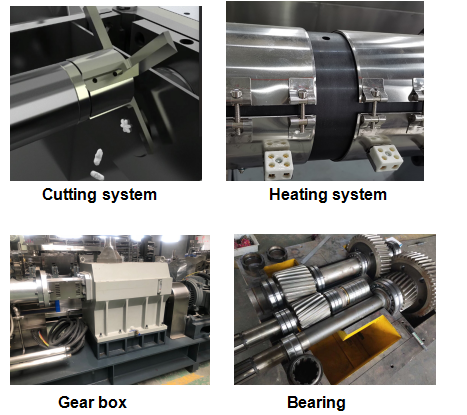

Corn Flakes Making Processing Main Machine Details:

Corn Flakes Extruder |

| 1. Frequency converter to control feeding device, extrusion screw, rotating cut. 2. Well designed screw sets for twin screw extruder ,widely application, low cost. 3. Wearable alloy steel screw lives a long life. 4. Imported bearing group with higher bearing capacity 5. Automatic lubrication system ensure running stable and long life 6. Self-cleaning function and different slenderness ratios is another feature of twin screw extruder. |

Air Roller Dryer |

| Dispersed particles, to avoid overlap pressed together into a tableting machine. |

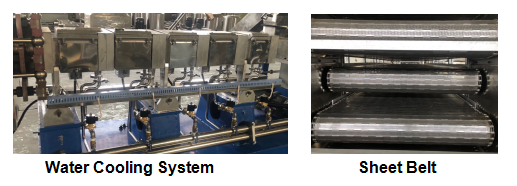

Tablet machine /Flaker/ Presser |

| As a key machine of the Corn Flakes Making Processing Puffed Extruder, this machine has high automaticity, can adjust the gap between compression rollers to ensure the thickness of products.Two compression rollers can adjust the gap between 0.3-3mm, and guarantee press uniformly, the inner of two compression roller are all have the constant temperature recirculating water, to ensure the temperature of compression rollers in order to avoid the stickness of materials. |

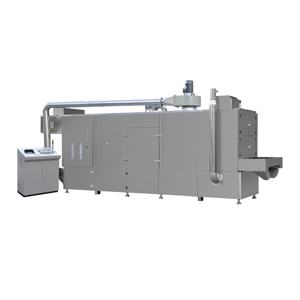

Oven |

| As Corn Flakes go through the oven, they will be dried quickly in a clean condition. In the Corn Flakes Making Processing Puffed Extruder, this oven can dry materials quickly after presser step. temperature between 0-200 degrees self-regulation through the control cabinet,internal stainless steel double mesh bag,baking time may be adjusted according to the speed,remove the water. |

Hot Air Heater | | Using the advanced technology in this field of high temperature air heating method, this method can puff the material in a short time in order to make them more puffed. The reason for using high temperature air is that materials can be heated evenly and quickly. We designed automatic leftover collecting device with the equipment, it also has characteristics like friendly interface and easy to operate. The Air Heater was build up by heating porters, stainless conveyor belt, automatic leftover collecting device, hot air pipes and warm keeping pipes. Equipment applied hot air convection and circulating flow principle.

|

Melting Sugar Machine |

| The Melting Sugar machine is the assistant equipments for the line. It was buildup by warming Jar and the mixing motor, used for mixing and melting the water, sugar and other additives.

|

Sugar Sprayer |

| The sugar sprayer was buildup by the roller and spraying system, the roller was drive by a motor, corn flakes will enter the roller from one end, so they can rolling with the roller and the sugar will sprayed on the corn flakes evenly. The volume of liquid sugar is adjustable. Sugar coating roller with insulation system

|

Oven with Cooler |

| After the sugar sprayed, the corn flakes will enter the oven automatically, to vaporize the water inside the sugar. This design has many advantages such as multipurpose usage and heating system balance etc. This equipment is used for vaporize the water inside the corn flakes, working progress non-stopping, drying time adjustable. At the end of the oven, there is a cooling belt, it will cooling the corn flakes fast, and makes the sugar agglomeration. |

Automatic Packing Machine |

| Combination head weigher Vertical automatic packing machine. Which is chosen according to the weight of your packing bags and shape. Together with packing machine, air compressor, nitrogen system is also optional according to your basic requirements. |

Corn Flakes Making Processing Puffed Extruder Technical Parameter:

Model parameter | DS65 Corn Flakes Making Processing Puffed Extruder | DS75 Corn Flakes Making Processing Puffed Extruder | DS85 Corn Flakes Making Processing Puffed Extruder |

Installed power | 180kw | 200kw | 240kw |

Power consumption | 126kw | 140kw | 168kw |

output | 120-150kg/h | 200-300kg/h | 300-500kg/h |

Length | 48m | 58m | 68m |

Main Accessories:

Company Information:

Factory:

Package & Shipping:

1) Packaging: daub coal oil on the surface to protect the machine from moisture, Then cover with plastic film. Finaly pack them with wooden case.

2) Customer's requirement is available.

Customers:

As Corn Flakes Making Processing Puffed Extruder producer, we have actually exported automated assembly lines to more than 80 countries as well as areas, such as South Africa, India, Malaysia, Indonesia, Brazil, and more. Some Corn Flakes Making Processing Puffed Extruder clients become our representatives in their area. We wish to have lengthy friendly organization partnerships with more customers from throughout the globe in the future.

Our Services:

Before sale services for Corn Flakes Making Processing Puffed Extruder

1. Provide the free consultation of the equipment

2. Provide the standard device and the flow chart

3. According to the clients' special requirement, offering the reasonable plan and free design helping to select the equipment.

Services during the sales for Corn Flakes Making Processing Puffed Extruder

1. Help client design the factory and offering professional advice, free engineering drawing for the factory layout.

2. Welcome to visit our factory .

3. Inspect the machine before leaving the factory.

After sale services for Corn Flakes Making Processing Puffed Extruder

1. Oversea install and debug the equipment.

2. Train the first-line operator.

3. Provide the basic formula

4. Operation/ Service/ Maintenance Manual: Provided in English.

Exhibition Review:

FAQ

1. What is your machine warranty ?

One year, main parts warranty time will be 2 or 3 years.

2. Do you supply spare parts ?

Yes, we supply spare parts with reasonable price;

3. What can you provide for after sale service ?

We can send engineers to your factory for installation and training if customers' required.

4. If we show you our layout of factory, can you help to design the whole process line ?

Yes, our experienced engineers and technical employee can help you to arrange the layout and installation of whole process line based on your real situation;

5. How can we contatc you if we meet problems during production ?

Phone/email/wechat/whatsapp/Skype are all available.

6. If we have samples of new products, can you help to analysis and design the machine ?

Yes, Our technical department can help to analysis, design and test the new products you offered.