soya protein machine

- HXSD

- China

- 30 Days After Order

- 15 Set/month

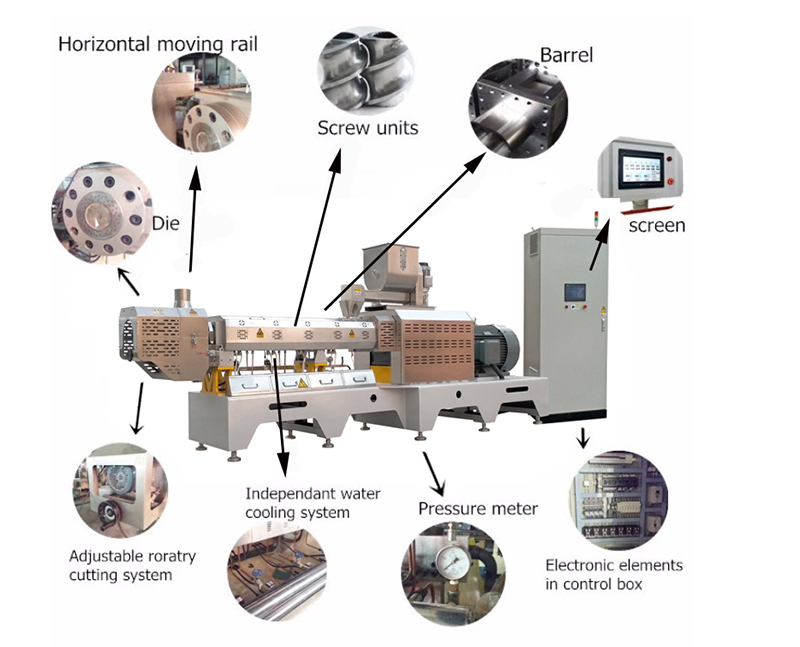

DS75 IV twin-screw extruder is the most advanced twin-screw extruder dedicated to the production of soybean protein products. It adopts screw with the L:D ratio of 45:1, equipped with multiple sets of shear blocks, resistance ring, and various screw segment to fully extrude, knead, and cut, so that the materials can be fully expanded and matured; The temperature control system adopts 12 groups of independent temperature zones for temperature control. The extrusion part is timely electrically heated and water-cooled through PID control logic, and the temperature control accuracy can be within plus or minus 2 degrees. This DS75-IV twin-screw extruder and its supporting production line are mostly used for the production and product research and development of medium and high-end standard soya meat protein products, and can produce sheet, column and granular meat protein products of various sizes

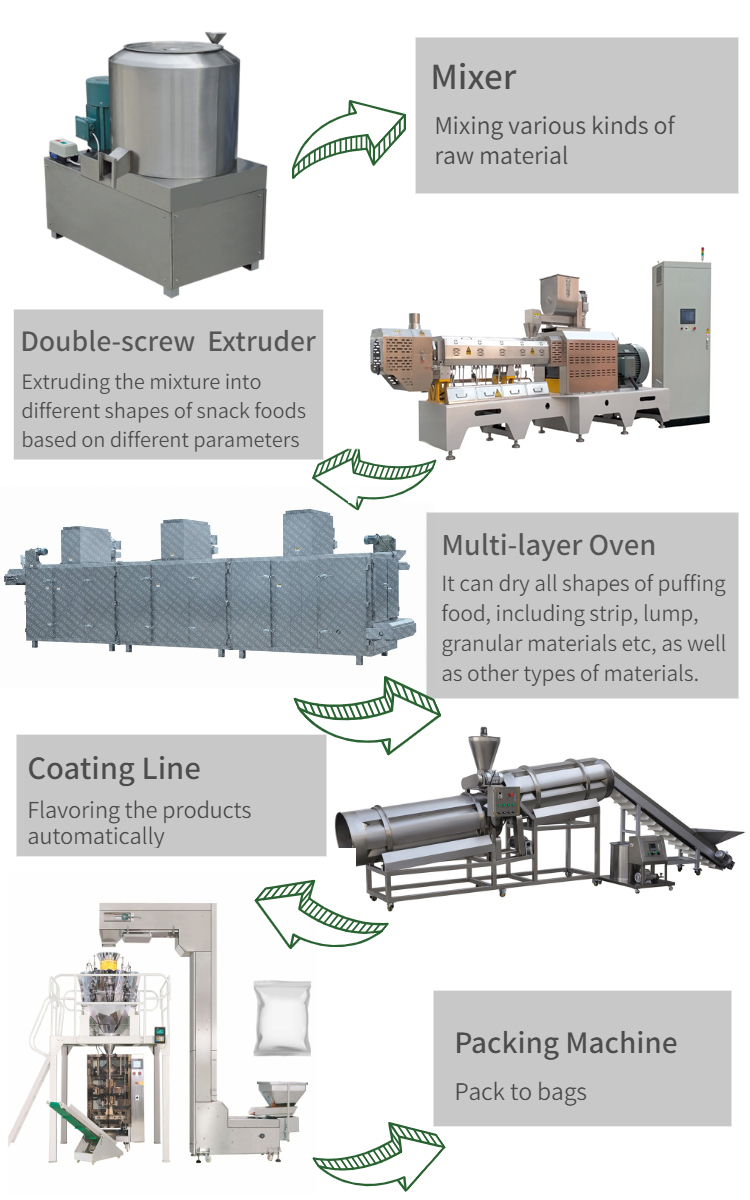

soya protein machine is a new kind of inflating processing line which is produced and developed according to our rich experiences and the requirement of food market. This line adopt low-temperature soybean meal as main material to produce new food which looks like muscle and has the sense of mastication. This kind of food has high nutrition and can be widely applied in many industries: ham, cam, fast-food, instant-cool food etc.

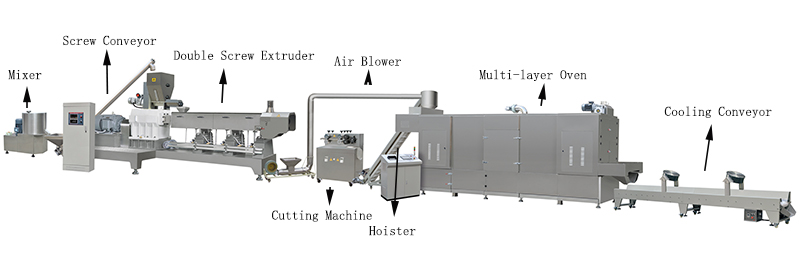

soya protein machine Processing:

Production line sample

Model parameter | DS65 Processing Line | DS75 Processing Line | DS85 Processing Line

|

Installed power | 80kw | 105kw | 125kw |

Power consumption | 60kw | 85kw | 105kw |

Output | 120-150kg/h | 200-300kg/h | 300-400kg/h |

Length | 22m | 28m | 28m |

DS75 IV twin-screw extruder is the most advanced twin-screw extruder dedicated to the production of soybean protein products. It adopts screw with the L:D ratio of 45:1, equipped with multiple sets of shear blocks, resistance ring, and various screw segment to fully extrude, knead, and cut, so that the materials can be fully expanded and matured; The temperature control system adopts 12 groups of independent temperature zones for temperature control. The extrusion part is timely electrically heated and water-cooled through PID control logic, and the temperature control accuracy can be within plus or minus 2 degrees. This DS75-IV twin-screw extruder and its supporting production line are mostly used for the production and product research and development of medium and high-end standard soya meat protein products, and can produce sheet, column and granular meat protein products of various sizes; The products produced have high degree of expansion and ripening, and obvious layered and filamentous structures; Fully expanded after foaming, with excellent toughness

Double Screw Extruder

Shaping machine

our advantage

1. Textured Fiber Soya Protein Food Production Line main motor brand is SIEMENS.

2. Relay: ABB or customized.

3. Inverter ( used to control the speed of the main motor , feeding system and cutting system ) brand can be Delta, Pioneer, CHNT or Schneider.

4. All the electric device brand can be customized as you need.

5. Baking machine source can be designed use Electricity, Gas, Oil or stream.

6. Machine material generally is Food grade stainless steel, also can customized as require.

7. Guarantee Time is 2 year.

8. After-sales Service Provided: Free spare parts, Field installation, Commissioning and training, Field maintenance and repair service, Video technical support, Online support.

Main accessories