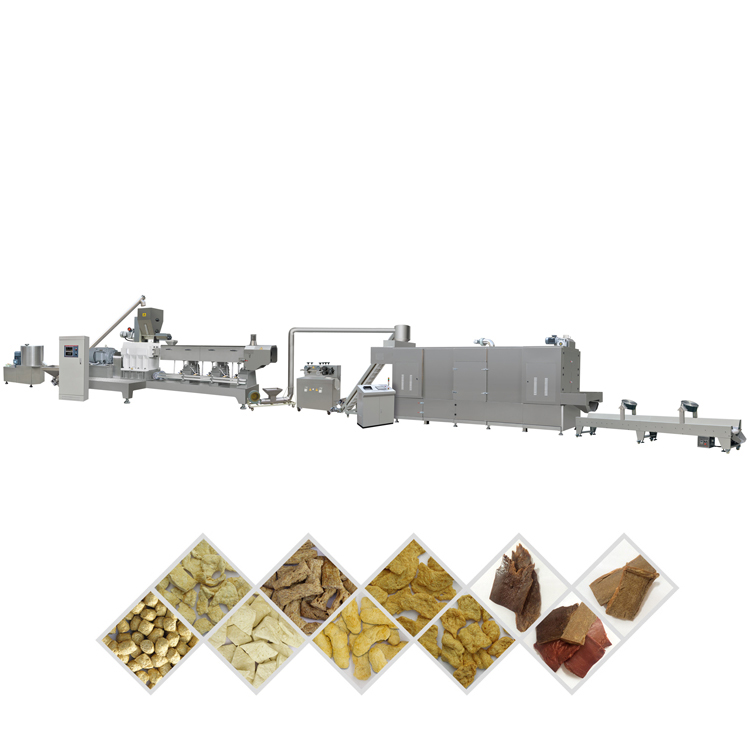

HME HMEA Textured Soy Protein Machine

Soy meat, or soya meat, a meat analogue or nutritious meat extender is made through HME HMEA Textured Soy Protein Machine. After the soya protein food is extruded from the HME HMEA Textured Soy Protein Machine, the food is sliced into granules, flakes, chunks, nuggets, goulash, steakettes by revolving knives, then dried in a rotary dryer.

Product Description:

Soy meat, or soya meat, a meat analogue or nutritious meat extender is made through HME HMEA Textured Soy Protein Machine. After the soya protein food is extruded from the HME HMEA Textured Soy Protein Machine, the food is sliced into granules, flakes, chunks, nuggets, goulash, steakettes by revolving knives, then dried in a rotary dryer. HME HMEA Textured Soy Protein Machine is made of stainless steel, it is with reasonable design and with high automation; The screws in the HME HMEA Textured Soy Protein Machine is made of alloy steel, with building block system structure and self-cleaning function.

HME HMEA Textured Soy Protein Machine Sample Show:

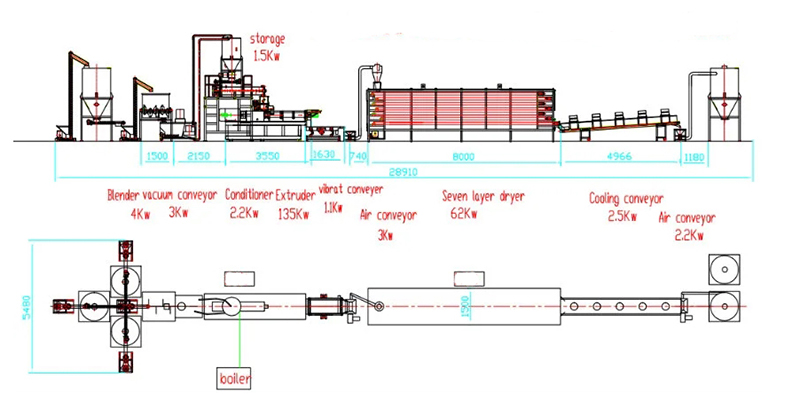

HME HMEA Textured Soy Protein Machine Flow Chart:

HME HMEA Textured Soy Protein Machine Technical Parameter:

Model | Output | power |

DS65 HME HMEA Textured Soy Protein Machine | 100-120kg/h | 90kw |

DS75 HME HMEA Textured Soy Protein Machine | 200-300kg/h | 120kw |

DS85 HME HMEA Textured Soy Protein Machine | 300-500kg/h | 135kw |

DS100 HME HMEA Textured Soy Protein Machine | 700-1000kg/h | 155kw |

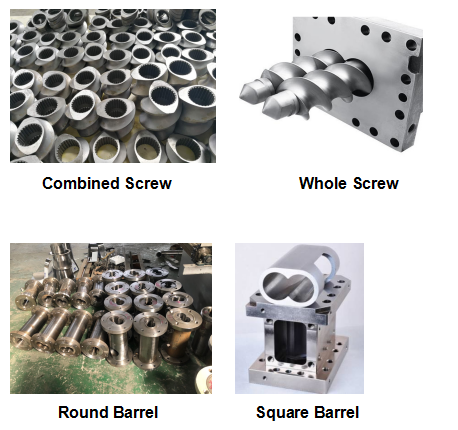

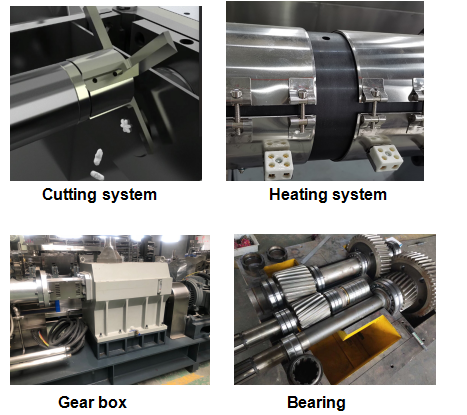

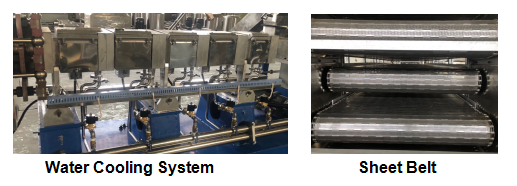

HME HMEA Textured Soy Protein Machine Main Details:

Vacuum Transporter |

| The feeding speed is fast and the continuous working time is long.

|

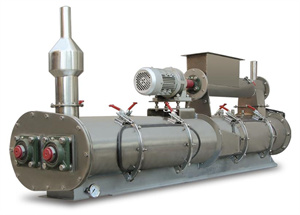

Pre-conditioner |

| The tempering device is a material that enters the tempering device with steam or sprayed water, and is uniformly mixed by high-speed stirring. The whole process is continuous and smooth without leakage, no dust, can replace the powder mixer and has high production efficiency and many functions. Features: 1. All parts in contact with the material are made of stainless steel; 2. Using imported nozzles, all the required water enters the conditioner in a mist; 3. The amount of water can be adjusted steplessly at any time to meet the requirements of different processes and different raw materials; 4. The conditioner can be filled with water or steamed for a wider range of applications. |

Double SCREW Extruder | | 1. Extruder adopts the design of combined functional screws. The production parameters can be controlled automatically and accurately. 2. Feeding, main driving device, and rotary cutting device adopt inverter to adjust the speed with more powerful drive, stable running, and low consumption. 3. Screw is made of alloy steel with long life. 5. Automatic lubrication system ensure running stable and long life |

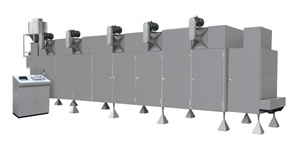

Dryer

| | 1. Heating source can be electric, gas, steam, fuel... 2. These series of roasting oven are widely used, 3. the user can choose different layer, length of dryer according to different product. |

Automatic Packing Machine | | Combination head weigher Vertical automatic packing machine . Which is chosen according to the weight of your packing bags and shape. Together with packing machine, air compressor, nitrogen system is also optional according to your basic requirements. |

Main Accessories:

Company Information:

Our Advantages:

1. High qulity: Using high quality material and establishing a strict quality control system, assigning

specific persons in charge of each part of production, from raw material purchase to assembly.

2. Professional R&D center. Employed designers with 10 years working experience in food indus-

try. Each month will release a new senies of products. OEM and ODM are warmly welcomed.

3. In General, the delivery date will be 20 working days for normal buy quantity. But if bigger order,

please check us further.

4. Small order accepted: Low MOQ accepted 2pcs are available.

Factory:

Package & Shipping:

Inside package is plastic film, outside is wooden or plywood case

(based on the customers' need).

Customers:

As HME HMEA Textured Soy Protein Machine manufacturer, we have exported the HME HMEA Textured Soy Protein Machine to more than 80 countries and regions, such as South Africa, India, Malaysia, Indonesia, Brazil and so on. Some of customers become our agents in their area. We hope to have long friendly business relationship with more HME HMEA Textured Soy Protein Machine customers from all over the world in the future.

Our Services:

I. We has professional team to design the whole production line according to your requirements

II. we also help our client to develop the old production line and carry out new products

III. Custiomized factory layout designed is provided by our professionals

IV. Overseas technicians are available to help the clients for installation and adjustment

V. 12 months warranty for the machines , 24 months for some parts

Exhibition review: