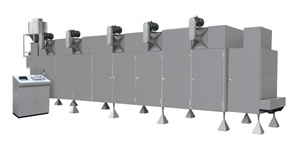

Rice Straw Making Machine

Rice Straw Making Machine using the rice produced in Asia, we have developed a rice straw that can be eaten directly. According to relevant reports, rice straws look like ordinary plastic straws, can be soaked in hot drinks for 2-3 hours, hold longer in cold drinks, and rice straw can be eaten, tastes like rice casserole, tastes a bit hard. The production process of rice straw is not complicated. Rice Straw Making Machine is composed of 70% rice and 30% tapioca starch. It is the material for making pearls in pearl milk tea.

Rice Straw Making Machine using the rice produced in Asia, we have developed a rice straw that can be eaten directly. According to relevant reports, rice straws look like ordinary plastic straws, can be soaked in hot drinks for 2-3 hours, hold longer in cold drinks, and rice straw can be eaten, tastes like rice casserole, tastes a bit hard. The production process of rice straw is not complicated. Rice Straw Making Machine is composed of 70% rice and 30% tapioca starch. It is the material for making pearls in pearl milk tea.

Rice Straw Making Machine Flow chart:

Mixing→Extruding→Cutting→Cooling→Drying

Rice Straw Making Machine Sample Show:

Rice Straw Making Machine Technical Parameter:

Model | Output | power |

DS65 Rice Straw Making Machine | 100-200kg/h | 80kw |

DS70 Rice Straw Making Machine | 100-250kg/h | 90kw |

DS75 Rice Straw Making Machine | 200-350kg/h | 105kw |

DS85 Rice Straw Making Machine | 300-500kg/h | 120kw |

DS100 Rice Straw Making Machine | 700-1000kg/h | 150kw |

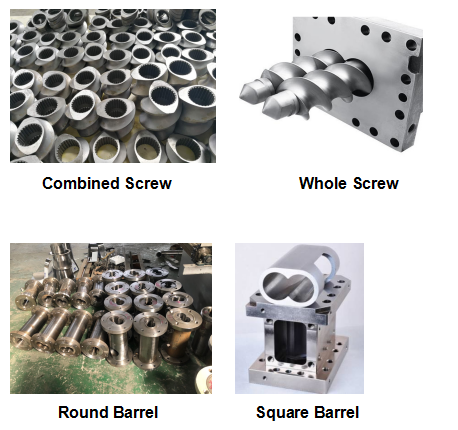

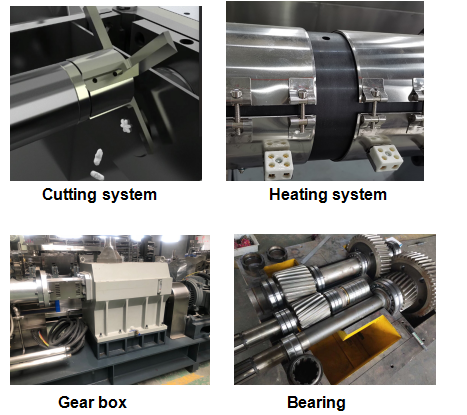

Rice Straw Making Machine Main Details:

Double SCREW Extruder | | 1. Extruder adopts the design of combined functional screws. The production parameters can be controlled automatically and accurately. 2. Feeding, main driving device, and rotary cutting device adopt inverter to adjust the speed with more powerful drive, stable running, and low consumption. 3. Screw is made of alloy steel with long life. 5.special design of our gearbox by our company .long service life |

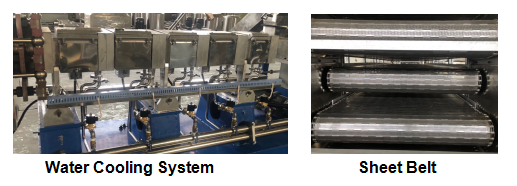

Dryer

| | 1.Heating source can be electric, gas, steam, fuel... 2. These series of roasting oven are widely used, it is used for drying all kinds of stick, piece, grain etc. puffed snacks, nutritional powder, bread crumb, pet food, textured vegetarian protein etc. 3. the user can choose different layer, length of dryer according to different product. 4. Drying temperature and time can be adjusted, effect of drying is capitally. |

Main Accessories:

Company Information:

Factory:

Package & Shipping:

Inside package is plastic film, outside is wooden or plywood case

(based on the customers' need).

1. Only plastic film nude packing with wooden pallet.

2. We can supply fumigation package and certificate.

3. Shipping, train, express or upon clients' demands.

FAQ

Q1. What's the pre-sale service of your company?

Related machines' technical parameter will be supplied to customer.

1.1 According to customer's factory size, factory layout can be provided in advance.

1.2 According to customer's material cost, general formulation can be prepared well.

1.3 Special machine can be supplied as customer's request.

1.4 Professional Advice about Market, machines, processing, materials, packing can be supplied.

1.5 Suggesting professional ship agent or helping book ship as customer request.

Q2. What's the after-sale service of your company?

2.1 Allocation chart as the buyer's request will be supplied.

2.2 Operation manual will be supplied after shipment.

2.3 One year warrantee, life time maintenance with cost price.

2.4 Free easy broken spare parts will be sent with container .

2.5 First installation can be done by engineer.

2.6 Training workers in customer's factory.

Q3. If machines wearing parts need changing, what should we do?

A3. We can offer the wearing parts all the time, and offer video.

Q4. What's the payment terms if we want to buy the machines?

A4. L/C, TT 30% down payment, 70% balance before delivery.

Customers:

Our Services:

About installation and after-sale service system

1. We can provide factory layout according to customer’s factory size in advance.

2. When we received your deposit of this order, we will ask our engineers to prepare to apply the visa, when the processing line arrived your country,

and we will send two engineers to go and help you to install the line, teach your worker(3-4 workers) how to operate the line, until your worker know the 3D line well.

3. Our engineers has responsibility to teach your worker how to clean the extruder, how to change the screw, how to change barrel etc.

and we have responsibility to provide technology support with you forever.

4. Our engineers can provide basic formula for producing the snack food etc. and help customer to produce good quality food according customer’s detailed formula.

5. We provide the spare parts will at preferential price for an extended long time.

6. other item:

a). Free consultation service before, during, and after sales;

b). Free project planning and design services;

c). Free debugging of equipment until everything is functional;

d). Free management of equipments' long distance shipping;

e). Free training of equipment maintenance and operating personally;

f). Free new production techniques and formulas;

g). Provide 1 year complete warrantee and life-time maintance service;

Exhibition review: